In the 70s of the last century, an energy crisis ensued, which entailed the need for an active search for alternative building materials with higher thermal insulation qualities. These materials were supposed to save electrical resources and heat.

History of creation

For several years, experts conducted hard work, the fruit of which became porous blocks. They received the second name - warm ceramics, and were patented in the early 80's. in Italy. More than 30 years have passed since then, and today ceramic blocks are officially manufactured in 32 countries of the world. The porous blocks received the aforementioned name for the reason that they have excellent heat-saving qualities. In their manufacture, environmentally friendly components are used that are mixed with clay and have the full range of characteristics of traditional bricks. But if we make a comparison with a brick, then the ceramic blocks weigh less, have better thermal insulation qualities and cover an impressive area at a low consumption.

Positive characteristics

Porous blocks have advantages over bricks. Among the advantages, it should be noted the porous structure, which allows to obtain higher qualities of sound insulation and heat saving with less weight. Among other things, such products are large, which allows you to complete the construction of houses in a shorter time. They are durable, have high strength and guarantee lower consumption of the solution. Even 20 years ago, the consumer knew 2 types of ceramic blocks, today there are several dozen of them. Products differ in size, format, purpose, performance and other properties. The most popular porous blocks are marked like this: 2.1 NF or 14.5 NF. The designation indicates how many times the product is larger than modern brick. They are used for commercial and residential construction, from which they form parapets, load-bearing walls, partitions and fences. A building erected from this material will have a microclimate suitable for a person inside, providing good sound insulation and keeping warm.

Main advantages

Porous blocks have many advantages, with their help you can erect walls, the thickness of which will vary from 38 to 50 cm. At the same time, there is no need to use additional insulation in the form of expanded polystyrene and mineral wool. Not one modern building material is capable of boasting such advantages. Despite the fact that many consumers consider the cost of a porous ceramic block to be quite high, it saves a considerable amount. This is due to the absence of the need for thermal insulation, as well as material savings. After all, if the wall of the porous block has a thickness of 50 cm, that it will turn out to be as warm as that made of ordinary brick, only the thickness of the latter should be equal to two meters. Large-format porous blocks provide good vapor barrier, protecting residents from noise. After the construction is completed, you will receive walls that are already prepared for the finish. The master will not need to equip the crate, fix plywood or gypsum plaster to cover the surface with plaster or use wallpaper as a decoration. The surface is quite smooth, has high adhesion with any materials. Such a wall can be immediately faced with brick or covered with plaster.

Additional advantages

A house made of porous blocks has many advantages. For example, for its construction it is not necessary to erect a heavy foundation, as for a brick building. For the construction of porous blocks will need the simplest construction of the base. The consumer will be able to save even at the stage of transporting the blocks, since the products weigh much less than ordinary bricks. Even an inexperienced builder will be able to cope with the technology of laying ceramic blocks. The large size of the products and the absence of joints can simplify the installation and save on the solution. Concrete consumption will be three times less compared to brickwork. Thus, it will be possible to save not only on transportation, installation and foundation, but also on the finish. Brick walls need to be primed, leveled and refined. But the perfectly smooth seamless surface of ceramic blocks allows you to cope with the plastering work in the shortest possible time.

For reference

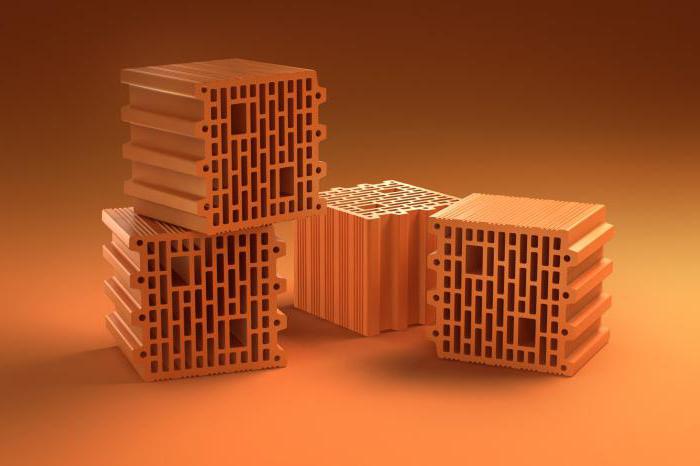

Large-format ceramic porous blocks have an interesting pattern of voids, which cannot be called random. This arrangement of cavities allows you to get the most balanced heat transfer, which provides vapor barrier and breathing to the wall. In homes made of such products will be comfortable and fresh, as the walls will provide natural ventilation. For the same reason, they always remain dry, since condensate water evaporates due to microventilation. Additional advantages are fire safety and environmental friendliness, as well as resistance to deformation.

Main disadvantages

The disadvantages of porous blocks are not numerous, but they exist. The first of them is fragility. However, if the masonry is carried out according to technology, then the load on the products will be distributed evenly, and the ceramic blocks will be able to withstand a lot of pressure. However, as practice shows, if you drop a separate brick, and also hit it with something solid, then it will crack. These are just clay products, the fragility of which is quite high. Therefore, craftsmen should take protective measures during the installation and transportation of blocks. The material has thin walls, and if you look at it in section, the block consists of many partitions. Therefore, during internal finishing work, there will be a need to make holes in the wall and hammer anchors into it. Only in this way you can hang a radiator, a shelf or a gas column. With the help of simple short dowels, this problem cannot be solved, so it will be necessary to stock up on long fasteners.

The cost of Porotherm blocks

On sale you can find porous Porotherm blocks, which are presented in a wide assortment. For example, the 51 Green Line variety costs 118 rubles. apiece and is intended to form load-bearing external single-layer walls that do not provide for additional insulation. For dressing the vertical joints of the masonry, the Porotherm 51 1/2 variety is used, for which one unit you will have to pay 199 rubles. These products are additional elements to the large-format unit. For dressing the seams of the masonry, the Porotherm 44 1/2 block is used, which costs 168 rubles. a piece. It approaches the large-format Porotherm 44 block . For load-bearing external walls with additional thermal insulation, Porotherm 38 blocks are used, the cost of which is 109 rubles. a piece.

Masonry

The laying of porous blocks is carried out after wetting the surface of the previous row with water. The solution is applied along the entire base of the wall to the outer edges. Each row should begin with the installation of corner bricks. It is necessary to ensure that the step between the vertical seams of adjacent rows along the wall is 125 cm. The horizontal and vertical position of the laid blocks should be checked using a plumb line and level.