Not so long ago, almost all heat exchangers had a shell-and-tube construction, in which the media rush to each other, moving along the tubes. The last elements are placed one into the other. But today, such a heat exchanger device is a thing of the past. Such devices are quite bulky, but they function quite efficiently. Among their shortcomings, one can single out a large consumption of the heated medium. Considering the types of heat exchangers, you should notice that today the new devices are replacing the above - plate high-speed units.

The principle of operation of the plate heat exchanger

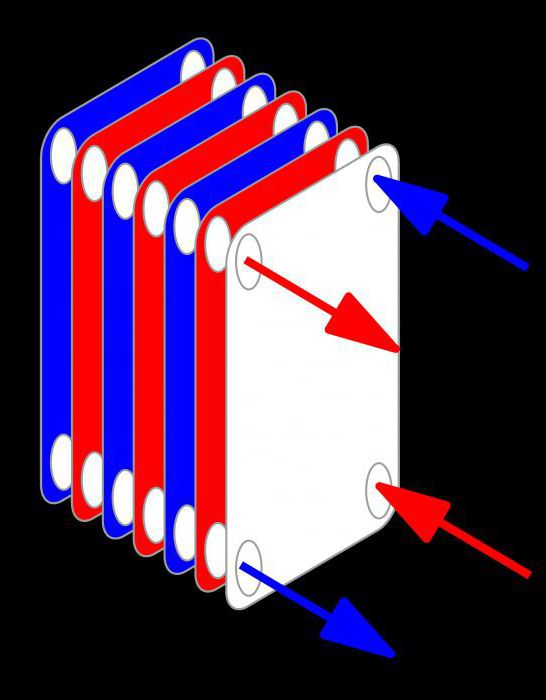

Considering the types of heat exchangers, you need to pay special attention to the plate variety of such devices. Structurally, such devices differ from the shell-and-tube predecessor. In the latter, the surface area of energy exchange increases due to the impressive length of the coil, which certainly became the reason for the more impressive size of the device. If we are talking about a new heat exchanger, then the goal is achieved by increasing the number of plates that have the same area. Modern types of heat exchangers have the same power, but they are 3 times smaller in size than shell-and-tube models. New devices provide an impressive flow rate of the heated medium, which is used for the needs of hot water supply. This led to the fact that the unit acquired a second name - it is called a high-speed heat exchanger. Such devices include return and supply pipes, which are used to connect the heating medium, the latter being the coolant.

Device and features

The device has an outlet and inlet nozzles of a heated medium. You can notice in the design a fixed plate, which is located in front. There are holes in the apparatus for water to enter. The heat exchanger will not work even without a sealing gasket, which is represented by a ring, as well as a heat exchange working plate. There is a rear movable plate and upper guides in the design. The device is equipped with a back support, a stud and a gasket, which is located along the contour of the plate.

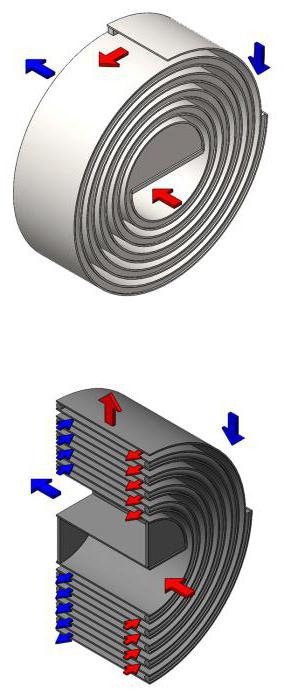

The described types of heat exchangers are used for heating a simple design with pipes that are located on opposite sides of the device. Between the plates, which are on two guides, a certain number of plates are clamped with a seal between them. On the plates to increase the exchange surface there is a relief corrugation. In some models, the connecting pipes are located on one side of the device, they are located on the front plate, which, however, does not affect the functioning of the plate device. Plate heat exchangers work according to the principle, which involves filling the space between the plates with a heated medium.

Additional work information

The shape of the gaskets determines the order of filling: in one section they open the way to water, in another section, heat is absorbed. During the operation of the devices of each section, in addition to the last and the first, you can notice a fairly intense heat exchange through the plate on both sides. Media flow through the sections, heading towards each other. The heating medium enters from above, and exits through the lower pipe. As for the heated, it follows the direction opposite to the heating medium.

Varieties of heat exchangers

On sale today you can find a cast-iron heat exchanger, but there are other devices that are made of other materials. Varieties of such devices are presented in a wide assortment. Their application is not limited to one area of the industry; today, units are used everywhere: in metallurgy, chemical industry, energy, at heating stations, in heating, air conditioning and ventilation systems.

Differences in heat transfer method

If you want to install a furnace with a heat exchanger, you should first understand the varieties of the devices described in the article. So, they can also be distinguished by the method of heat transfer, in this respect they can be surface and mixing. In the first case, heat transfer occurs between different media through walls made of heat-conducting special material. In this case, the contours remain completely tight. If you are interested in surface-type equipment, then you should be aware that regenerative and regenerative devices exist. In the latter case, the temperature exchange between the heat carriers occurs through the thin walls of the contours, while the flow of the medium has the same direction. In the second case, the flow direction may change. If you decide to install a gas heat exchanger, then you should pay attention to the mixing varieties of devices. Heat is transferred to them by mixing two media, but devices of this type are used less frequently than those indicated above.

Varieties of heat exchangers by area of use

When the owner of a private or country house decides to install a furnace with a heat exchanger, he most often chooses a shell-and-tube system, which includes a bundle of pipes connected to each other in a grate by welding and soldering. Another variety is plate heat exchangers, which were discussed above, they have a heat transfer area, presented in the form of plates. The latter are interconnected by heat-resistant gaskets. Concentric coils are used for mounting cast heat exchangers, the working medium in them moves along curved pipes, as well as the space between the pipes.

You can not lose sight of the spiral devices, which are represented by thin metal sheets. They are rolled up in a spiral during the manufacturing process. The presented list is not complete; among the most common, airborne as well as waterborne devices can be distinguished.

The heat exchanger, the price of which can be 7,000 rubles, is presented today in a wide variety. It is simply impossible to list all types of such units, therefore only the most popular were presented above. The leader among them is lamellar.

Varieties of plate devices

Plate heat exchangers are available for sale in a wide range, they can be collapsible, soldered, welded and semi-welded. The first variety was discussed above, but as for the soldered version, it has corrugated metal plates made of stainless steel. These elements are interconnected by soldering in vacuum using nickel or copper solder.

Conclusion

The heat exchanger (price presented above) can also be welded. Such devices are designed for operation in high temperature and extreme pressure conditions. They are used in installations whose parameters do not allow the use of sealing elements.