Perhaps the main aircraft unit is the wing. It is the wing that creates the lifting force that keeps the multi-ton aircraft in the air, preventing it from falling. It is no accident that the designers have an expression that the one who owns the wing also controls the aircraft. The pursuit of improving the aerodynamic characteristics of aircraft forces developers to constantly improve the wing, working on its shape, weight and profile.

Profile Wing

The wing profile of an airplane is the geometric section of the wing that runs parallel to the axis of the airplane. Or easier - side view of the wing. Over the many years of development of the aircraft industry, various laboratories and institutes have constantly developed and tested wings of various configurations. Speed, mass of aircraft increased, tasks changed - and all this required new wing profiles.

Profile Types

Today, there are various wing profiles that differ in purpose. The same type can have many options and can be used on different aircraft. But in general, the existing basic types of profiles can be illustrated by the image below.

- Symmetric.

- Asymmetrical.

- Flat convex.

- Biconvex.

- S-shaped.

- Laminated.

- Lenticular.

- Diamond shaped.

- Wedge-shaped.

On individual aircraft, a varying profile is used along the length of the wing, but usually its shape is constant throughout.

Geometry

Outwardly, the wing profile resembles a worm or something like that. Being a complex geometric figure, it has its own set of characteristics.

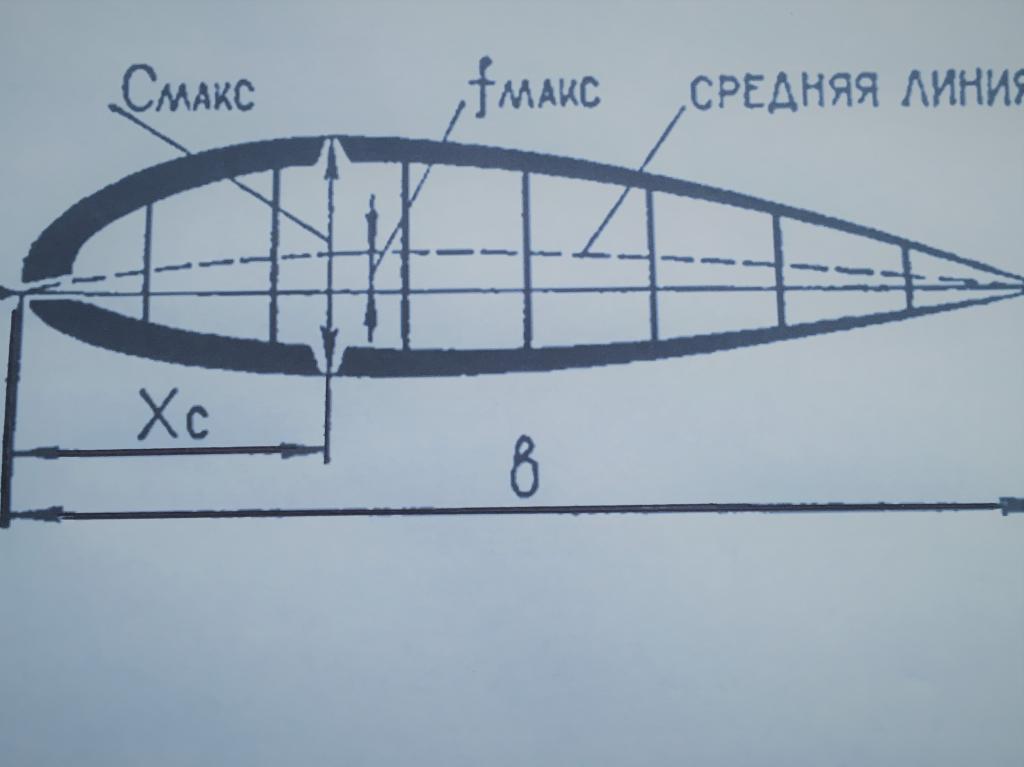

The figure shows the main geometric characteristics of the wing profile of the aircraft. The distance (b), called the chord of the wing, is the distance between the extreme points in front and behind. The relative thickness is determined by the ratio of the maximum thickness of the profile (Cmax) to its chord and is expressed as a percentage. The maximum thickness coordinate is the ratio of the distance from the toe to the maximum thickness (Xc) to the chord (b) and is also expressed as a percentage. The middle line is a conditional curve equidistant from the upper and lower wing panels, and the deflection arrow (fmax) is the maximum distance of the midline from the chord. Another indicator - relative curvature - is calculated by dividing (fmax) by chord (b). Traditionally, all these values are expressed as a percentage. In addition to the already mentioned, there is a radius of the nose of the profile, the coordinates of the greatest concavity, and a number of others. Each profile has its own code and, as a rule, the main geometric characteristics are present in this code.

For example, profile B6358 has a profile thickness of 6%, a concavity arrow position of 35%, and a relative curvature of 8%. The notation system, unfortunately, is not unified, and different developers use ciphers each in its own way.

Aerodynamics

Fancy, at first glance, drawings of wing sections are made not because of a love of high art, but exclusively for pragmatic purposes - to ensure high aerodynamic characteristics of wing profiles. These critical characteristics include the lifting coefficient Su and the drag coefficient Cx for each particular profile. The coefficients themselves are not constant and depend on the angle of attack, speed and some other characteristics. After conducting tests in the wind tunnel for each profile of the wing of the aircraft, a so-called polar can be compiled. It reflects the relationship between Cx and Su at a certain angle of attack. Special directories have been created containing detailed information about each aerodynamic profile of the wing and illustrated with corresponding graphs and diagrams. These guides are freely available.

Profile Selection

The variety of aircraft, the types of propulsion systems and their purpose require a careful approach to the selection of the wing profile of an aircraft. When designing new aircraft, several alternatives are usually considered. The greater the relative thickness of the wing, the greater the resistance. But with thin wings of great length, it is difficult to ensure proper structural strength.

Separately, there is a question on supersonic machines requiring a special approach. It is natural that the profile of the wing of the An-2 aircraft (corncracker) will differ from the profile of the fighter and passenger airliner. Symmetrical and S-shaped wing profiles create less lift, but are stable, a thin wing with a small bend is suitable for high-speed sports cars and fighters, and the wing profile with the highest lift can be called a thick wing with a large bend, used on large passenger aircraft. Supersonic planes are equipped with wings having a lenticular profile, and for hypersonic planes, diamond-shaped and wedge-shaped profiles are used. It should be borne in mind that by creating the best profile, you can lose all its advantages only because of poor-quality surface treatment of the wing panels or unsuccessful aircraft design.

Characteristic Calculation Method

Recently, the calculation of the characteristics of a wing of a certain profile has been carried out using computers that are capable of multivariate modeling of wing behavior in different conditions. But the most reliable way are natural tests conducted on special stands. Individual “old school” employees may continue to do this manually. The method sounds simply menacing: "a complete calculation of the wing using integro-differential equations for unknown circulation." The essence of the method is to represent the circulation of the air flow around the wing in the form of trigonometric series and to search for the coefficients of these series that satisfy the boundary conditions. This work is very time-consuming and still gives only approximate characteristics of the wing profile of the aircraft.

Aircraft wing design

A beautifully drawn and detailed calculated profile must be made in reality. The wing, in addition to performing its main function of creating lift, must perform a number of tasks related to the placement of fuel tanks, various mechanisms, pipelines, electrical harnesses, sensors and much more, which makes it an extremely difficult technical object. But speaking very simply, the wing of the aircraft consists of a set of ribs that provide the formation of the desired profile of the wing, located across the wing, and the side members located along. Top and bottom, this design is covered with aluminum paneling with a stringer set. Ribs on the outer contours fully correspond to the wing profile of the aircraft. The complexity of manufacturing the wing reaches 40% of the total complexity of manufacturing the entire aircraft.