In metalworking processes, abrasive and cutting tools play a key role. It is a snap in the form of cutters, which are installed in machine chucks by means of shanks. The quality of the tool is affected by the characteristics of the tool, and the reliability of its fit is ensured by a collet. What is the clamp in the processing equipment in principle? This device is an auxiliary part of the cartridge, but due to differences between different types of shanks and machine designs, there are many variations and sizes of this element.

Collet design

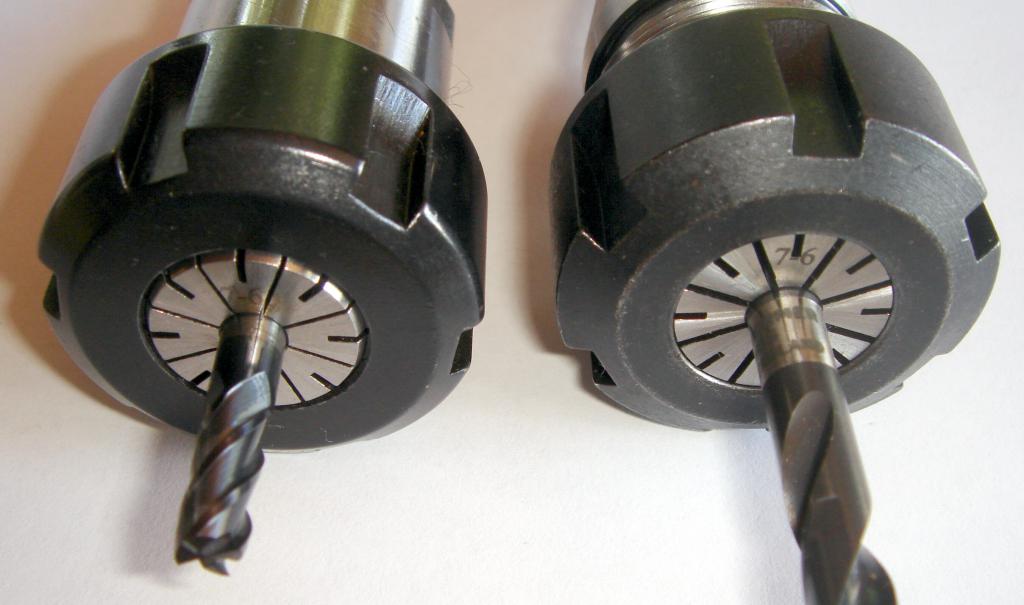

The part is made in the form of a split spring sleeve with a truncated cone. On the surface of the body there are also cuts that provide the mobility of the clamping tabs when removing or installing the milling nozzle. Directly gripping the shank is carried out due to the force from the nut. What is a collet in terms of interaction with a cartridge? This is a component of a metal-cutting machine design, which is initially worn on a cartridge for a working tool and performs a kind of adapter function.

The mounting equipment of the collet itself is, as a rule, universal. Different models can be used for one group of machines. But the part that secures the milling shanks is almost always focused on a limited range of sizes. As for the material of manufacture, the structural basis is formed by metal - usually tool steel. Unless in places of interfacing with a fixed mill, inserts from solid alloys and special ceramics can be used. This is necessary to increase the wear resistance of the working surfaces and to prevent the sticking of the hot shank to the collet.

Product Dimensions

The collet can be used in machines of various types, which determines the breadth of its size ranges. On average, we can talk about the following parameters:

- Length - from 35 to 70 mm. Moreover, the standard is 35.5 mm.

- The diameter of the clamping head is from 8 to 13 mm.

- Thread length - from 9 to 16 mm.

- The depth of the groove profile is the usual format 2x0.8 mm.

- Landing diameter - from 6 to 22 mm.

The gradation of the size range does not in any way determine the relationship between different characteristics. For example, a typical turning collet for an 8 mm milling cutter can have a length of 70 mm, and a part with a landing diameter of 10 mm can be 45 mm. Much of the size is determined by the nature of the processing. Mechanical action can be performed obliquely on some machines, which, for example, complicates the use of long elements. The same applies to restrictions on the combination of clamping mechanisms with the headstock of a machine of various calibers.

Features of Collet Chuck

This device is easily confused with a cam chuck, which is used not only in machines, but also as part of manual processing tools. They are combined in that they act as a universal means of gripping the nozzle. However, in both cases, universality is conditional, since we can talk about certain sizes of shanks. The main feature of the collet chuck is the ability to adjust the clamp according to the diameter of the tool used. Moreover, fastening can be provided with respect to shanks with different cross-sections and shapes. Usually cylindrical and rectangular rods are used, but there are also special models for capturing triangular elements.

Classification of collet types by purpose

The configuration and functionality of the collet fixtures varies depending on the place they occupy in the gripping mechanism. The most common elements are of two types:

- Clamp collet. The classic and most common sleeve design with multiple shock absorbing petals for universal grip. As a rule, such a collet for the machine is used in the processing of workpieces with a diameter of 30 to 80 mm.

- Supply collet. Also performed in the format of a sleeve with spring tabs formed due to three incomplete cuts along the cylinder of the housing. Ready for use, the petals are pressed together.

Separately, it is worth noting detachable collets, which are used specifically in the processing of small-format products. Such devices support the ability to disassemble and modular layout - at least allow inserts to be updated.

Classification by technical device

A typical collet differs from many cartridges in that it can be easily removed and, as noted above, even disassembled in some modifications. But collet fixtures differ in the way they are combined with machine tools. In the same metalworking, static non-separable (fixed) and built-in removable models are involved. Also the collet chuck can be retractable and retractable. Belonging to one or another group is determined by the gripping configuration of the processing tool, the range of angles of mechanical impact, and the control system, since there are manual and to some extent automated assemblies for setting up equipment.

Applications for collet fixtures

Advantageously, such devices find a place as a tooling element for turning, drilling, rotary and longitudinal machines. This applies to one part of the installation, but what is the collet in terms of compatibility with the processing tool? Among the target means for capturing, taps, dies, drills and mills can be distinguished. The specific compatibility will be determined by the type of shank. By the way, not only machines use similar systems for fastening processing parts. A hand-held power tool is also provided with spring-loaded chucks with a screw nut, only in a smaller format.

Collet manufacturers

The premium manufacturers include Metabo, Jet, Bosch, Makita and other manufacturers, which are also involved in the development of equipment for solid billets. For example, the common collet for the 8 mm milling cutter in the Bosch line is also suitable for grinding hand machines of its own production. As for the cost, the products of the above-mentioned brands are estimated at 700-1,200 rubles. per collet element. Kits with parts of different formats and additional equipment can cost 15-20 thousand rubles. Domestic products from Zubr and Enkor enterprises are slightly inferior in quality of execution, but cost 15-20% cheaper.

Conclusion

The use of auxiliary transitional parts when fixing the processing nozzles does not in itself add reliability to the working process. Intermediate nodes also reduce security. What justifies the use of universal cartridges with spring segments? To answer, you need to turn to another question - what is a collet in the general technological process of processing? This is an element due to which the operations of selecting and changing the same cutters and taps are optimized. The operator does not need to select the nozzle for the cartridge strictly for a specific format for a long time. It is enough to carry out the collet layout and insert the part into the cartridge. Of course, in such a system there are limitations, but the range of variations when combining a working tool with equipment is wide enough for the complete universalization of equipment within a certain enterprise.