A chainsaw is one of the indispensable tools in a private household. It is very important that this tool functions continuously and without interruption. The quality of the chainsaw depends on the reliability of the carburetor. As it is used Walbro. This carburetor is quite reliable. But sometimes he also needs tuning, maintenance and repair. Well, let's look at the features of this site.

Mechanism device

The device is supplied in an aluminum case, which is made by casting. Inside it there are internal channels with contours. These are diffusers. Air passes through them, which is then absorbed by the internal combustion engine.

The diffuser has fuel channels. When air passes through an element, it flows with gas in a stream, forming a combustible mixture.

The fuel pump, the nozzle system, as well as the mechanism for adjusting the mixture parameters are installed externally and integrated into the Walbro carburetor. The power that the chainsaw engine can develop, as well as the amount of air in the carburetor, is controlled by a throttle. Impulse chamber of a fuel injection pump. It is supplied through a pulse channel that connects to the engine boat. When the piston in the cylinder moves, the pressure in the crankcase changes. These changes affect the operation of the fuel pump diaphragm. The pump starts forcibly, while its operation is synchronized with changes in pressure in the crankcase. Its level depends on the engine speed. Fuel is supplied to the carburetor from the tank through a special carburetor fitting. Passes through the diaphragm, intake and exhaust valves on the fuel pump, and also through the filter. Next, the mixture passes through the fuel channel past the needle into the chamber where the control membrane is located. The needle valve, or rather the needle, is connected to the membrane by means of a lever. The camera located below it through a special hole enters the atmosphere.

Operating principle

Walbro carburetor for chainsaw functions by changing the pressure in the crankcase. At the beginning of the suction stroke in the diffuser, air begins to flow through the diffuser. Its volume depends on the engine speed and its load.

It also depends on the position of the

throttle. It is controlled by a special handle. Using fuel jets, during the passage of air, a mixture is formed. Further, gasoline is sprayed and a finished mixture is obtained, optimal for combustion. Usually it is prepared in a ratio of 1 to 14. Then the mixture will fall into the cylinders, where the combustion cycle takes place. Due to the fact that the volume below the control membrane is connected to the atmosphere, it moves up. Then, using the lever, she pulls the needle along, opening the fuel channel. So, the next dose of fuel gets into the camera. As the fuel chamber fills with gasoline, the membrane will go to its usual place. The needle valve closes and, as a result, the correct amount of gasoline appears inside the chamber. It will be fed through the jets. This process is cyclical and constantly repeats. To adjust the amount of fuel that will come from the fuel jets, there is a diffuser. The Walbro carburetor is equipped with tuning screws. The first is the main one, the second is to adjust the idle speed. As a result of the rotation of these screws, the mixture is enriched or depleted. If you unscrew them, then the mixture becomes richer. If you spin it, it’s impoverished.

It is necessary to choose the optimal ratio so that 1 kg of fuel accounts for 14 kilograms of air. The manufacturer additionally provided the ability to adjust idle speed. This screw can be found outside. If you screw it, it rests against the lever mounted on the axis of the throttle. By rotating these screws, you can independently adjust the carburetor to obtain the required power in a variety of conditions.

How to understand that carburetor adjustment is required ?

There are several signs that may indicate that Walbro is not working properly. The carburetor in these cases must be adjusted. If the engine of the chainsaw starts with great difficulty and stalls immediately after starting, the reason for this phenomenon is in the non-optimal fuel mixture. In other words, she is too poor. Also, the carburetor requires tuning, if suddenly the saw began to consume too much fuel. Another sign is the greater amount of exhaust gases. This is a signal that the mixture is not completely burnt. She is too rich. The mounting screws of the adjusting screws may be broken. This happens due to strong vibrations and various defects of the protective cap. This phenomenon is very rare in Walbro products. The carburetor can then be easily repaired. Another problem is blockage. Often the carburetor channels, diffuser and cavities can become dirty due to poor-quality fuel or a defective air filter. Too worn engine pistons also affect carburetor operation.

In this case, setting up a Walbro carburetor, if it helps to solve the problem, is only temporary. In this situation, it is necessary to overhaul the motor.

Identification of problems in the carburetor and typical malfunctions

Often owners of chainsaws are faced with a leak of fuel. In order to diagnose this, an external examination is necessary. To do this, it is recommended to remove the device and check the integrity of the gasket. It can be found between the device and the crankcase. If everything is in order with the gasket, then the device is checked for leaks. All malfunctions, which we will consider later, affect the level of tightness. Many of them can be fixed if you purchase a Walbro carburetor repair kit and replace damaged or malfunctioning parts.

How to check for leaks?

The fuel supply hose is put on the input channel of the measuring device. Then the tap opens, if any. Then, with a pear, a certain amount of air is pumped into the carburetor cavity. In this case, the pressure gauge should show at least 0.4 bar. If after some time the pressure remains the same, then you have a working Walbro carburetor. Repair is necessary if the pressure drops. There may be several reasons.

This is a malfunction of the fuel pump diaphragm. It may be damaged. Holes or tears occur on it. The malfunction is eliminated by replacing the membrane with a new one, from the repair kit.

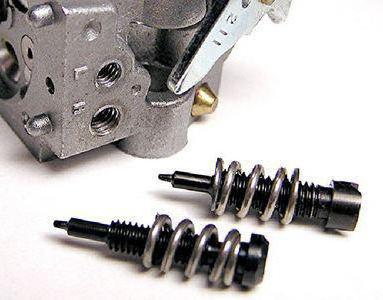

Needle valve

Sometimes the needle in the valve cannot completely close it. This situation can occur due to blockages, severe wear or a damaged needle cone. The valve lever also loses its mobility, its geometry is disturbed. The spring elasticity changes.

Membrane

Tightness is reduced due to the loss of shape of the control membrane. This may occur due to overheating, prolonged operation of the device.

Inlet and outlet valve

This problem may occur in the fuel pump.

The fact is that at the petals of the valves their “flatness” leaves. They no longer cling to their supporting planes, the tightness is broken. The result is a loss in pump performance. He no longer pumps fuel in the right amount. Why does this happen? Everything is very simple. The owner used the saw for a long time with another fuel, and not the one recommended by the manufacturer Walbro. Because of this, the carburetor often overheated. As a result of such a malfunction, a too

lean mixture is prepared

, the engine is poorly lubricated. This can lead to more serious problems. These are badass in the cylinders, problems with starting, unstable operation of the unit in all modes. Also among the problems with the fuel pump can be identified membrane deformations in the area of the pulse chamber, pollution and slags. Many of the symptoms in carb work are often associated with blockages. Cleaning and flushing can restore the device to function. There is a special spray for this.

Carb adjustment

The setup process is quite simple, especially if you already have a similar experience. The first thing to do is to tighten the screws that are responsible for the maximum and minimum turns clockwise. They can be designated as H and L. They should be twisted all the way. Then, by half a turn, the screws are unscrewed. All manipulations are performed on a drowned motor. After completing this procedure, the motor must be started and warmed up at medium speed.

Idle setting

It is recommended that this screw be turned counterclockwise until the engine runs as smoothly as possible.

It is important to keep an eye on whether the chain is moving. If it rotates, then you should still tighten the screw. When in this mode the motor starts to stall, the screw is slightly unscrewed back.

Testing work after setup

Check how the Walbro carburetor works. Adjustment may not give the desired result. For testing, the engine is started, warmed up and gently pressed on the accelerator. If, as a result, the turnover has increased to a maximum, then everything works correctly. If this does not happen, screw L is turned counterclockwise 1/8 of a turn. The maximum engine speed of the chainsaw is approximately 11.5 thousand revolutions per minute. If their number is higher, this can cause disturbances in the ignition system. In the event of a malfunction, screw H is turned counterclockwise, thereby reducing the maximum speed.

Conclusion

Knowing the Walbro carburetor device and its principle of operation, you can easily adjust it to work in the required modes. The device is simple and even people without experience will be able to cope with it. Any problems can be eliminated with your own hands without significant costs.