The beautifully faced facade of a house or building always attracts attention. Moreover, any types of finishing work should be planned at the design stage, and it doesn’t matter if a new building is under construction or an old one is being renovated. When choosing materials, you should give preference to those that have received good reviews. Facade thermal panels, for example, have appeared on the building materials market for a long time, however, in European countries, and in Russia they began to use them only recently.

What is a thermal panel?

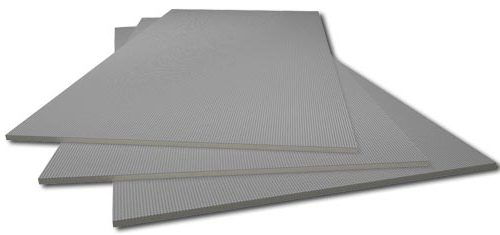

This innovative material was presented by experts from Germany 40 years ago. It was obtained as a result of a combination of durable clinker tiles and polyurethane foam, which is a good insulating material. This combination has made facade thermal panels with clinker tiles one of the highest quality and most reliable materials for decorating. It turns out that with the help of one material two goals can be achieved at once: on the one hand, the facade will have an attractive appearance, and on the other, its thermal insulation will be achieved. As you know, polyurethane foam has excellent insulation properties. The process of manufacturing a thermopanel is that polyurethane foam is poured into special forms, where clinker tiles and various fasteners are already laid. As a result, a seamless material without joints is obtained, which allows for excellent thermal insulation.

What is the difference?

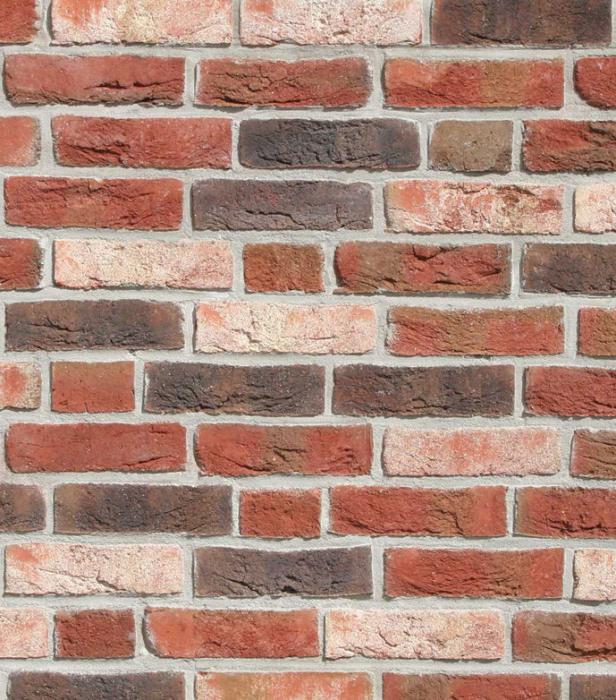

Facade thermal panels receive positive reviews not at all by chance. Firstly, modern manufacturers offer a huge selection of shades and textures. For example, a smooth surface is ideal for applying glaze on it or imitating it under a stone or wood. Secondly, during installation, all joints are hidden due to the use of a special solution that strengthens the structure. Thirdly, the material is distinguished by good heat and waterproofing performance, while the process of its installation is simple and convenient.

Benefits of Thermal Panel Finishes

Facade thermal panels (for brick or other materials) for decorating buildings and cottages today are used more and more often. Their main advantage is that these panels are a unique combination of thermal insulation properties and decorative cladding. Accordingly, you can significantly save on the purchase of additional materials. In addition, many are attracted to this material in that when it is used, the surface is obtained without joints, and this makes it possible to minimize heat loss. Good waterproofing properties are the guarantee that moisture will not enter the room.

Externally, facade thermal panels with clinker tiles are very aesthetic and attractive, therefore with their help any facade can be given a specific architectural appearance. In addition, clinker tiles are easy to care for, high strength and maintaining an attractive appearance for a long time. It is important that the panels have an acceptable weight, therefore, additional reinforcement of the foundation is not required.

When to install?

As a rule, finishing work is the last stage in the construction or repair of a house. If you choose facade thermal panels with clinker tiles (reviews about them are exclusively positive), you should know a few basic rules before installing them:

- Panels are mounted on special guides on fasteners.

- It is possible to sheathe the facade at any time of the year, since the work is carried out quickly enough without the use of special equipment or compliance with a certain temperature regime.

- Thermal panels are quite light, so the pressure on the base of the house will be uniform.

German-made products: features and reviews

Facade thermal panels were first produced in Germany, and today certified products are available both in Europe and in Russia. The use of innovative technologies, coupled with high-quality raw materials, makes facade slabs with clinker tiles the most optimal choice for finishing various residential and commercial buildings. The use of polyurethane foam, which is simply ideal for thermal insulation of the facade and surpasses mineral wool or polystyrene foam in many respects, plays a large role in popularizing the material.

Polyurethane foam is a rigid, non-meltable thermosetting plastic having a mesh structure. This material occupies about 97% of the volume of the entire panel, while only 3% of its volume is solid material. The peculiarity of polyurethane foam is that it is resistant to solvents, acids and alkalis, does not collapse under the action of fungus or rot, and also has no smell. At the same time, polyurethane foam is absolutely safe.

Production technology

When choosing building materials, we focus primarily on reviews. Facade thermal panels in this regard are an ideal choice, since they are known as reliable and high-quality heaters and at the same time decorators of facade structures. The process for creating thermal panels is as follows:

- Clinker tile is added to the matrix in the mold, to which quartz sand is subsequently added: thanks to it, the joints during installation will be reliably protected from external factors.

- Plasticizers are also added to the matrix - they contribute to improved adhesion of the material to the surface.

- The mold is filled with liquid polyurethane foam, which hardens and forms a single system with clinker tiles.

Since clinker ceramics are made of crude clay and have many pores, liquid insulation penetrates well into them, due to which the thermal panels become even stronger. The production technology eliminates the appearance of harmful substances in the material, while it meets all existing requirements and standards.

Thermal panels front under a stone or other material are used for decoration or repair of the facade. At the same time, work with the cladding is carried out without preparatory work, and the panels are fastened to the outer wall with dowels.

How is the installation done?

The panels are connected to each other through a tongue-and-groove connection, so the installation process is quick and not very difficult. Thanks to such a connection, there is no need for gluing the connecting tiles, and the adhesion strength of the material and the wall surface becomes much higher. Clinker thermal panels are front, reviews of which are only positive, can be attached to the wall from any material - aerated concrete, brick, limestone, sandstone, wooden beams or frames. At the same time, there is no need to strengthen the foundation.

Installation of thermal panels is carried out in several stages. First, horizontal and diagonal lines of the facade are drawn. Then the panels are fastened in the first row. First, a horizontal profile is set, and then rows of thermal panels are laid from left to right. All seams should be foamed with mounting foam. Then the next row is fastened. And at the last stage of work, the seams are sewn. To fill the joints, use a special frost-resistant grout, which is suitable for wide joints. You need to work with it only at positive temperature.

How to choose facade thermal panels?

The photo shows how diverse solutions can be implemented using this interesting material. You can purchase thermopanels based on polystyrene foam or polyurethane foam. Each of these varieties has its own characteristics, and therefore it is worth considering carefully before making your choice. At the same time, the use of this material is the confidence that the facade of your house will be impeccable, bright and memorable.