Our country for the most part lies in those latitudes that provide significant changes in annual temperature - from frosty events to searing heat. In this sense, in order to improve the comfort (thermal insulation) of the home, people have to thicken the walls. However, thick walls can exert noticeable pressure on the foundation. The question is how to solve this problem. The answer can give a special brick, hollow and durable.

This material is much lighter and easier to handle than simple building materials. Hollow ceramic bricks make it possible to build thinner walls, while maintaining the properties of absorption of noise and heat. In addition, the floors from it do not lose in strength, as is the case with solid brick. The use of such bricks in construction is convenient and beneficial for two reasons. Firstly, the cost of the material is reduced due to the saving of raw materials and energy resources, and secondly, construction will require less material.

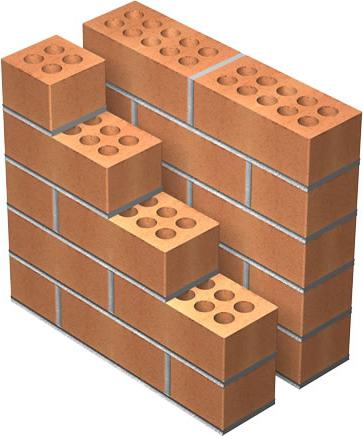

Hollow brick is molded from clay. It differs from other building materials by the presence of holes of various shapes, sizes and quantities. The slots can be either through or through recesses. Round and oval hole shapes greatly reduce the likelihood of unwanted cracking during brick making. The resulting air volumes closed in the product increase the thermal insulation properties of the material. It is important that the solution is sufficiently thick and does not fill the gaps, thus displacing the air from the cavities. This will reduce the efficiency of using bricks. The maximum volume of slots in relation to the whole figure can reach 50%, but the average figure is within 36%. Such a percentage of voids will allow to achieve the best operational properties of bricks.

Of the types of products existing on the market - ceramic hollow and solid brick - each has its own advantages and disadvantages. For example, the solid volume of the figure allows you to use it for laying the foundation, bearing parts of the building, where the hollow version is forbidden to use due to the high probability of freezing, tearing and breaking into pieces. It is also not recommended to use hollow bricks for the construction of furnaces - due to the constant change in temperature and frequent overheating of the material, its integrity is violated. A solid brick, on the contrary, accumulates heat due to its mass. Such properties will be combined as a base and cladding - a full-bodied body accumulates heat, and a hollow one - retains.

Hollow brick finds effective application in the construction of small-sized residential premises. In the case of the construction of non-residential and, accordingly, unheated buildings, it will be more expedient to give preference to another type of brick. The hollow version will come in handy for the construction of internal walls and partitions. Based on the strength properties, brick with holes is produced under the following brands - M-75, M-100, M-125, M-150, M-200.