Electromechanical machines are complex devices. Depending on the purpose, they can consist of many nodes, both mobile and stationary. But, among other things, the machine has a bed. This is the foundation on which all these nodes are fixed.

What is a bed

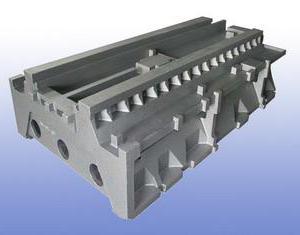

The bed for the car performs the same function as the frame for the car. Regarding it, all drive mechanisms produce their rotational or linear motion. Therefore, the design of the bed provides for the placement of all the guides and special seats on it, where different machine nodes are located. The configuration of the bed forms is very diverse. They are either solid or with stiffeners. Beds of small machines are often solid. Bulky machines are assembled on a composite base. The bed itself is a product that is mounted on a powerful foundation. According to technical standards, it must withstand not only static, but also dynamic loads. The bed should have strength and durability.

The material from which the frame is usually made is cast iron or low-carbon steel. Heavy machines are installed on reinforced concrete beds. High-precision machines - on beds made of artificial material based on mineral chips and resinous substances (syntheran). Beds of these types are little susceptible to deformations caused by temperature.

Varieties of beds

The bed is a cross-sectional shape of a different design with:

- ring type profile;

- box-shaped profile;

- box-shaped profile and stiffeners of longitudinal type;

- a box-type profile and a stiffener located diagonally;

- open profile type;

- open profile and double walls.

In the longitudinal direction, the bed is the base with:

- square windows;

- windows and stiffener diagonally in one direction;

- stiffeners in both directions (like the letter X);

- solid body design.

Machine bed

The bed of the lathe performs the function of the base. It has in its design two walls of longitudinal arrangement. These walls connect the ribs in the transverse direction. On top of the bed are guides, of which there are four pieces. Of these four, three are prismatic, and one is flat. In the left edge of the bed at its end there is a place where the headstock is fixed. In the opposite part on the edge from the inside of the guides, the tailstock is installed. On the bed along the guides, this headstock can be freely moved and fixed at any point. The plate carriage also moves along the bed guides, which are prismatic. In order for parts to be machined with high precision, all guide beds must be carefully machined in all planes. The strictest straightforwardness and parallelism must also be observed.

Repair work with a bed

In the process, the machine bed can be worn out, which leads to the need for repair. Basic malfunctions of the bed:

- The presence of cracks in cast iron material. To repair small cracks, welding with bimetal electrodes is used. When the crack reaches a size of more than 5 mm, then instead of welding, a connection with clamps is used. Initially, holes are drilled along both sides of the crack and steel mortgages are inserted. Further, these mortgages are connected with welding clamps.

- Depreciation of the bed guides. To restore these details of the bed, apply the method of scraping. Its essence lies in the fact that planing of surfaces is carried out cleanly with the help of wide cutters of scraper.