Beginning needlewomen often ask themselves how to properly insert a needle into an old or new sewing machine . After all, the thread immediately breaks when installed incorrectly, stitches are skipped or the device abruptly simply stops sewing. To avoid such problems, you should use a few tips below.

Needle device

The simplest and most ingenious invention is a machine needle. Of course, compared to manual, it is more complicated. But if one day to understand her device, then there will never again be a question about how to insert a needle into a sewing machine.

The device of the needle does not depend on what type of machine - mechanical or electrical. All machine needles have one design:

- shaft or blade;

- thickened flask;

- point;

- the ear;

- the grooves are long and short;

- scandal.

Varieties of sewing machines

Two sewing machines can be divided into two groups: domestic and industrial. With household, everything is much simpler. In such machines, the needle is often already inserted. And if you still have to replace it, then there will not be a question about how to insert the needle into the household sewing machine, since the place in it for the tool is made specifically by its shape, that is, it is inserted in one single way.

The situation is somewhat more complicated with industrial sewing machines, because if the needle is not inserted correctly, the unit will simply not work. Threading in most industrial machines is necessary from left to right. But it is also known that the thread is inserted from the side of the long, and comes out from the side of the short groove. That is, during the installation of the needle, it is necessary to pay attention to the fact that the long groove looks to the left and the short groove to the right (exactly the opposite, everything happens in a household machine).

Instructions on how to insert a needle into a sewing machine

- First you need to carefully study the attached instructions for the sewing machine. If you have a good idea of how the machine and the sewing process are arranged, there will be no question of how to insert the needle into the sewing machine. It will just be necessary to strictly adhere to the manufacturer's requirements.

- It must be noted that a sewing machine can be adjusted to a specific standard of needles. If you use a non-standard tool, it will break.

- According to the thickness indicators, it is necessary to check the conformity of the new needle and thread. To do this, take the tool with a long groove up, put the thread into the groove and probe the surface of the blade. The thread should completely fill the groove, but not protrude above it, if this protrusion is formed - a too thin needle for the working thread is selected.

- If you manage to find a suitable needle, this is not the time to insert it into the needle bar: put the tool on a glass surface and raise it to eye level. If the rod is evenly spaced along its entire length, then such a needle can be used - it is not a curve.

- The nail plate must be held along the needle, it is necessary to start from the bulb. This determines whether the tip of the needle is blunt or not. If so, then you should not use such a tool.

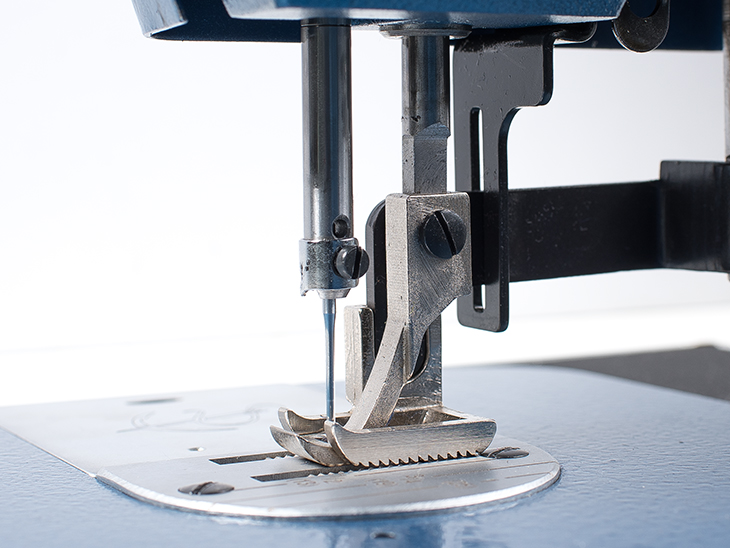

- Finally, a correctly selected needle is inserted into the sewing machine. Do not forget that a long groove when refueling in the needle bar always looks in the direction of the thread direction. To install the needle in the machine, it is necessary to raise the needle bar in the upper position and loosen the needle clamp screw, so that the groove will be visible, into which the needle is installed. The scaffold is attached to the bottom of the groove, the needle through the needle holder should go into the needle bar. It is inserted all the way, and then securely fixed with a fixing screw.

Double needle installation

Many beginning seamstresses are also wondering how to insert a double needle into the sewing machine. The answer to this question is very simple: a double needle can be installed in any sewing machine that sews in a zigzag pattern. The main thing that you should pay attention to before buying it is the width of the slit of the needle plate and the distance between the tools.

However, in a sewing machine such as Podolskaya, you cannot insert a double needle. Indeed, in such machines in the needle plate there is only one round hole, and to use a double needle, you will need a wide and narrow gap, which is also necessary in order to perform zigzag stitching. In addition, a stand for another spool and additional thread guides are required.

If you plan to insert a needle (double) into a sewing machine such as "The Seagull", you should pay attention to how it, when performing straight stitching, enters the hole in the needle plate. The tool should pass exactly in the center of the hole. If there is a displacement of the center, it can break.

Operation tips

There are some tips to help you less often face the problem of changing the needle in the sewing machine due to breakage. Here are these tips:

- you should never pull work cloth from under the paw with a movement toward you;

- Do not help a working machine by manually pushing a cloth;

- it is necessary to ensure that the needle plate is always firmly fixed;

- the foot should be set only after the needle is lowered;

- if you have to put a line across a thick seam, you must do this carefully and not at fast speeds;

- if the upper thread breaks, the sewing machine skips stitches and knocks strongly during operation, the needle must be replaced.

Half of the problems are due to improper maintenance of the sewing machine. Therefore, another important reason why the machine breaks the thread, makes gaps, etc., are lubricated parts. Therefore, in order to avoid problems, it is worthwhile to timely lubricate each part of the mechanism.

Incorrect needle installation: cause breakage

A tool that has been improperly installed causes problems. These malfunctions, in turn, make it impossible to continue the sewing process. The main problems are needle breakage and skipped stitches.

Machine needle failure reasons include:

- mismatch of needle number and fabric thickness;

- tool curvature;

- the needle is not fully inserted into the needle bar;

- the needle bar itself may be bent.

Skip Skips

The reasons for skipping stitches when replacing the needle are as follows:

- the needle is curved;

- the tip is dull;

- there is rust on the tool;

- the needle is inserted on the wrong side;

- needle mismatch with device type or fabric thickness.

Simple manipulations on installing the needle can affect the operation of the device in an unpleasant way. If you have problems with the tool or for some reason you need to repair the components of the sewing machine, it is best not to engage in amateur performances, but contact the service department for the repair and diagnosis of such units.