In a private house, the task of thermal insulation of floors does not cease to be relevant. The owners of their homes are trying to solve this issue with the help of different materials, each of which differs in its characteristics. In order to make the right choice, you must familiarize yourself with them.

The use of expanded clay

Insulation for concrete floors should have excellent sound and heat insulation characteristics, as well as strength, frost resistance and fire resistance. Many consumers pay particular attention to durability and environmental friendliness. Expanded clay possesses such properties. If you use a certain technology when warming, then even the coldest floor will gain excellent thermal insulation qualities. When using expanded clay, laying the waterproofing layer is more than relevant. Due to the fact that the described material has high porosity, it is able to easily absorb moisture, which can cause unpleasant consequences. After installing the waterproofing, it is necessary to spread the heat insulator. In order to achieve perfect uniformity, backfill must be equipped after the installation of guide beacons. The first of them is set indented from the wall by 30 millimeters. Subsequent elements should be mounted in parallel with the first. Between them, a distance must be maintained, which will depend on the length of the rule.

Expanded clay floor screed

If you choose a floor insulation on concrete for a balcony, then expanded clay can be preferred. This is due to the fact that this material does not have an impressive weight, which is most relevant for the described case. Before pouring the finish screed, it is necessary to work on arranging the fixation layer. To do this, mix water with cement. The result is a uniform suspension, which should not be too dry or too liquid.

This manipulation is necessary in order for the liquid mixture to fill all full spaces and displace air. After drying this layer, a monolithic insulated floor is obtained, which will not be afraid of moisture and heavy loads. The final step will be a screed for the final alignment.

Screed mortar

If the floor is insulated with concrete, it is important to properly prepare the mortar for pouring. The ratio of 60 to 40 is the most suitable ratio of cement and sand. The liquid should be added in an amount of 10-20% of the total weight of the dry mixture. Then all the ingredients are mixed, and the resulting solution is poured onto the expanded clay layer. At the next stage, the master must level the surface with a large spatula, the length of which is 100 centimeters.

Alternative solutions for concrete floor insulation

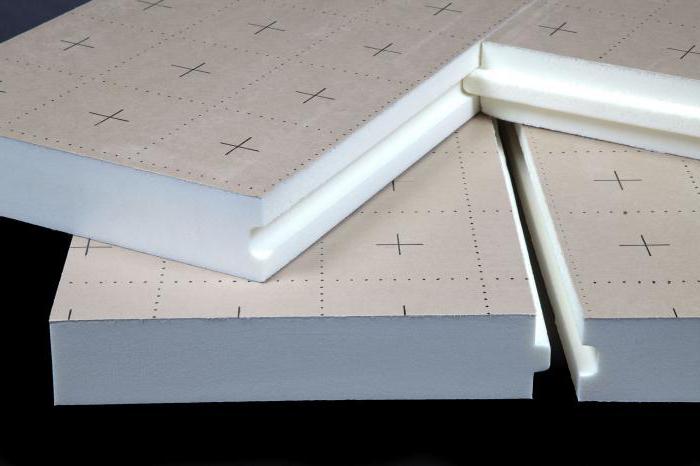

If you decide to choose a heater for the floor on concrete 10 mm thick, then you can prefer expanded polystyrene. It has excellent thermal insulation qualities, serves for a long time and has an affordable price. If you decide to equip a heated floor in the bathhouse , then this solution acts as the optimal one. Expanded polystyrene can be laid on an old coating made of ceramic tile, metal, wood or concrete surface. Thermal insulation is strengthened on the base, then a reinforcing mesh is mounted, only then you can proceed to the arrangement of concrete screed.

Features of the use of expanded polystyrene

Choosing a heater for a floor on concrete, you can get expanded polystyrene. Its insulation properties are 25 times better compared to expanded clay concrete. Among other things, this technique has a more pleasant operating experience. Due to the fact that polystyrene foam is not afraid of moisture, it can be used for work on balconies, as well as in rooms whose conditions are characterized by an increased level of humidity. Such insulation for concrete floors can be used to equip a floating screed.

Technology of work

For rough leveling, it is possible to use slabs of different thicknesses, however, it is recommended to fill the screed before installing the floor. This is true if the work is carried out on a balcony or loggia. Then a waterproofing film is laid, followed by expanded polystyrene, and then a reinforcing mesh is mounted. First, you will need to apply a fixing solution, for this you can use the composition to equip the screed. The layer should be 2 cm thick.

At the next stage, a final screed of 5-8 cm is poured. It is important to consider that at the final stage it is necessary to close up the technological gaps located around the perimeter. In this case, fiberglass or mounting foam is used. When a floor insulation for concrete polystyrene foam is used, it is important to consider that roll waterproofing is overlapped. Its width should be 10 cm. Separate strips should be fixed with adhesive tape. Then you can begin to arrange flooring.

The use of foam

Penoplex is a foamed polystyrene, which is characterized by low thermal conductivity and excellent sound insulation, as well as durability and moisture resistance. If you have a base with any design features and configuration, penoplex is the best option. After laying, the screed is arranged.

Floor insulation using the technology of spraying polyurethane foam

If you need insulation for concrete floors in the country, then you can prefer the thermal insulation popular today in the form of sprayed polyurethane foam. This insulation material is economical and also characterized by short deadlines. After application, you can get an even coating that is free from joints and joints. Other advantages of this technique can be distinguished, among them the possibility of arranging the floor base with an area of 100 square meters by one team. It is impossible not to note the insignificant transportation costs, this is due to the fact that polyurethane foam is supplied in special containers in the form of barrels, the volume of which is 200 liters. As a result, it is possible to obtain an insignificant layer thickness of 50-100 millimeters, which does not steal excess space.

If you decide to use such a heater for concrete floors on the balcony, it should be noted that it does not imply the use of additional vapor barrier. Due to its unique structure, the material is not able to form condensate. When used by spraying, you can insulate both inside and outside the building. In the latter case, we are talking about insulation of basements, facade walls, as well as structural joints, which are part of the ceilings. Polyurethane foam is not afraid of the effects of mold, rodents, as well as temperature extremes. The material can not be negatively affected by natural and climatic factors. After spraying polyurethane foam, you can lay any type of screed. If there is a need for insulation of the floor of the first floor, then the described technique acts as the most suitable solution.

Features of the use of sprayed polyurethane foam

When choosing a floor insulation for concrete under a screed, you may prefer polyurethane foam, which has a negligible thermal conductivity coefficient within 0.021 W / m * K VK. This characteristic makes the material a leader in its field. Spraying can be carried out on a surface that does not require additional preparation. However, the master still has to carry out dust removal, which will increase the adhesion characteristics.

It is worth considering that the adhesion quality of polyurethane foam is 1-2 kg / cm 2 , which looks impressive. It does not absorb water and is not able to pass water vapor, so there is no need to carry out additional moisture protection. When choosing a heater for concrete floors in a bathhouse, many owners of private houses face a problem that is expressed by the complexity of the configuration of the rough foundation. The described materials completely solve this problem, because they can be sprayed onto any surface, and the structure will repeat the existing relief. During the work, you can apply a thinner layer that will perform its tasks, which cannot be said about a number of competitive materials that suggest the need for a longer layer. This allows you to save space, for example, in baths, country houses, as well as on balconies and loggias.

additional characteristics

The insulation for the floor described above for concrete, the photo of which is presented in the article, does not require fasteners that could act as cold bridges. You can use this thermal insulation without worrying about the health of your loved ones, as it is environmentally friendly and does not cause allergic reactions. Manufacturers guarantee the life of the insulation, which lasts for 25-50 years, which will depend on external conditions and factors that affect the material. Polyurethane foam is not a favorable environment for the reproduction of bacteria and fungi, in addition, this thermal insulation is not of interest to rodents. After carrying out the work, you can count on improving the soundproofing characteristics of the floor. During the work, it is possible to spray material, the density of which can vary from 15 to 500 kilograms per cubic meter. The final value depends on the tasks.

Conclusion

Each of the above insulation materials has its own quality characteristics. The choice must be made only after you become familiar with their properties. For example, if polyurethane foam is sprayed with a density of 50 kilograms per cubic meter, it will perform the additional function of a waterproofing layer. If there is such a need, then you can spray the material in compliance with these features. Then you can save on the purchase of related materials.