For those who wish to carry out stationary installation or provide power to equipment, machines and machines, a wide range of different conductive systems is presented on the market of electrical goods. One of the most popular products is considered to be the PV-1 copper wire.

Since 1979, these electrical products comply with GOST No. 6323-79. Since 2010, the PV-1 wire is marked as PuV No. 53768. This means that this power wire can also be used as an installation wire. Information on what the PV-1 wire is, technical characteristics and the scope of this product are presented in the article.

Device

The PV-1 wire is made from tinned copper. If the product is single-core, then with its help only one communication line is laid.

The PV-1 wire consists of the following components:

- conductive copper core;

- isolation.

Lived

Depending on the cross-sectional class, the conductive core can be single or multi-wire. In accordance with GOST 22483, wires whose cross-section is from 0.5 to 10 mm. sq., contain a core of one wire and belong to the first class of rigidity. Products having sections from 16 to 35 mm. sq., equipped with seven wire cores, so that the flexibility of the wires increases. These products are also called PV-1. Cross section from 50 to 95 mm sq. have wires that contain at least 19 cores. Conducting electrical systems with a cross section of 12 cm square. equipped with 37 cores.

Insulation coating

Polyvinyl chloride plastic is used as a winding for PV-1 wires with the addition of various stabilizers, plasticizers, fillers and dyes to its base. Thanks to the use of insulating plastic compound, the wire has good electrical characteristics. Due to the hose compound, the insulation winding has high mechanical properties and resistance to external mechanical influences. Polyvinyl chloride plastic is used for the manufacture of both the outer and inner insulating layer.

The insulation coating may have various colors. Depending on the scope of the wires, the colors are applied to them in different ways. To perform grounding, the PV-1 wire is yellow-green in color. The cross section of the wires of such products does not exceed 6 mm. For wires with cross sections above 6 mm, the insulation coating is represented by eleven colors.

Also, the electrical conductive system can be completely painted over or contain longitudinal diametrically spaced stripes.

Abbreviation

- P - is the general designation of the class of an electrical product: wire. When marking conductive electrical products, the letters “” (cord) and “” (cable) are also used.

Sometimes a product is designated as follows: PuV. This means that the wire PV-1 is installation.

- B - indicates the type of insulation: polyvinyl chloride plastic. Due to its high physicochemical properties, it is a good dielectric.

- The number indicates which stiffness class the conductive core belongs to. The higher this figure, the smaller the bending radius of the wire.

Technical characteristics of the wire PV-1

- The cross section of the conductive wires varies from 0.5 to 120 mm square.

- The wire is intended for work with alternating voltage (450/750 Volts) and constant (1000 Volts).

- The frequency of the alternating current is 400 hertz.

- Climatic modification - UHL.

- The wire has an electrical resistance of 1 MΩ * km.

- Construction length up to 100 meters.

- The wire is characterized by high resistance to air humidity, mechanical shock, linear acceleration. Withstands bending, vibration loads and acoustic noise.

- The wire does not spread combustion. This feature is due to the use of an insulating winding prone to “attenuation” in the product.

- It is highly resistant to mold fungi.

- The service life of the wire is up to 15 years.

- Sold by bays from 20 to 100 meters.

- Upon purchase, the manufacturer provides a two-year warranty card.

What is UHL?

For each electric machine, device or other electrical product manufactured in the Russian Federation in accordance with GOST 15150-69, a corresponding type of climatic modification is provided. It is indicated by the letter part in the last group of characters. The climatic version of the wire PV-1 manufacturer designated: UHL. In order not to make a mistake when buying the necessary conductive electrical system, you need to know how these abbreviations are deciphered.

The letter "U" indicates that the product is suitable for wet, hot, dry, but moderate temperature conditions.

"HL" - a product with this designation can also be used in cold climates. Thus, it can be used at temperatures from -50 to +70 degrees.

Where is the wire used?

Due to its characteristics, the PV-1 wire is a universal electrical product. These products are used:

- During installation of stationary lighting and electric power lines.

- When connecting industrial equipment, various electrical appliances.

- At installation of interblock switching connections.

- When arranging grounding.

What should be considered during the work?

Using the power cable PV-1, its temperature range should be taken into account. You can operate the product at temperatures from -50 to +75 degrees.

For the installation of this conductive system, the temperature range must be at least -15 degrees. This means that at this temperature a previously unheated wire is not recommended.

The characteristics of the PV-1 wire make it possible to heat it up to 70 degrees.

In places where the wire will be laid, structural elements should not contain moisture condensation.

Where is the product placed?

Places for products can be:

- Hollow channels in building structures.

- Mounting boxes, trays and pipes.

- Switchboards and control panels for electrical equipment. The product in such cases is part of the harnesses.

- Construction channels, metal pipes.

- Plastic or metal trays.

- Plastic or metal pipes. The wires laid in them stretch along the ground.

What should I look for when buying?

Before you purchase a wire PV-1, experienced craftsmen recommend that you consider the following nuances:

- Perform an external inspection of the product. There should be no damage or deformation on the surface of the insulation coating.

- Check the structural dimensions of the wire. To do this, measure the cross section PV-1. It should correspond to the thickness of the insulating layer.

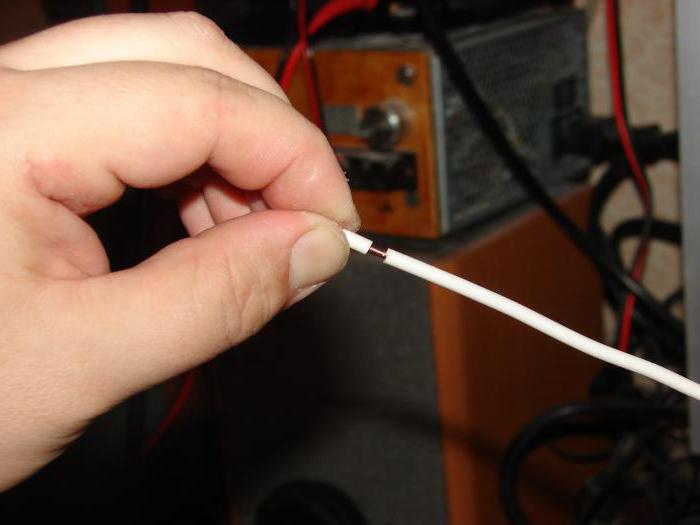

- Check the product for ease of stripping. To do this, using a construction knife, make an incision at a distance of 130 mm from the edge of the wire. According to GOST, during the cutting of PV-1, the insulation from the copper core should be separated easily and without gaps. If you have to make an effort to remove it, then this indicates that during storage of the wire the technologies and conditions of detention were violated or its shelf life has expired.

- Test the electrical resistance of the wire. You can use the same piece for this.

- Check bending strength. Work is carried out using a roller, the diameter of which must correspond to ten diameters of PV-1. The product is checked by wire passing through this roller. If at the end of the test there are no deformations on the surface of the conductive system, then this wire can be operated.

- Check marking. On the tags of bays PV-1, all necessary designations must be present: wire length, bay weight, manufacturing plant and date of manufacture.

Consumer opinion

Judging by numerous reviews, the following qualities are characteristic of the PV-1 copper wire:

- High moisture resistance. The craftsmen appreciated the ability of the wire to fully work at a temperature of 30 degrees in rooms with 100% humidity.

- Incontinence of burning.

- The wire functions properly even when interacting with chemically active materials.

High characteristics of PV-1 are appreciated by manufacturers of various electrical systems. Base PV-1 is also used to create high-voltage wires PVV-1 for the automotive industry.