Today in the field of construction of prefabricated structures, sandwich panels are very popular. They are used in the construction of frame houses, offices, industrial buildings, sports facilities. Method of application depends on the type of material.

Design features

Sandwich panels are large three-layer structures consisting of two sheets of rigid material and a heater located between them. To keep all these components together, they are pressed in a hot or cold way. For the insulation layer, polyurethane foam, mineral wool, polystyrene foam are used. The outer shell can be made of PVC, fiberboard, metal, ceramics, drywall. The metal lining is coated with such polymers as: pural, polyester, plastisol. Coatings have a variety of colors. The technology of installing sandwich panels allows you to use them in any terrain.

Varieties

There are several types of sandwich panels. They are distinguished by several criteria.

By appointment:

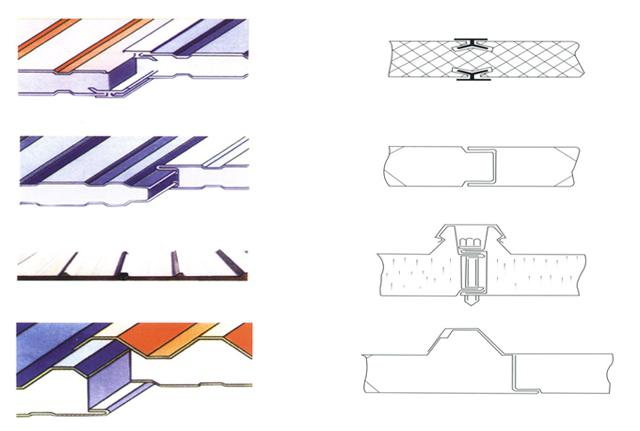

By profiling the surface of the panel:

- small-profile;

- smooth profile;

- trapezoidal;

- grooved.

Regardless of which installation of sandwich panels is carried out, its price depends on the amount of work. The larger it is, the lower the cost of 1 m 2 .

Sandwich Panel Mount

Panel mounting elements are selected depending on the thickness and type of construction being constructed. Usually, self-tapping screws are used for these purposes. To determine their required length, it is necessary to carry out a calculation - add a self-tapping screw, the thickness of the frame and washer to the panel thickness.

To protect against damage to the surface of the plate, as well as to ensure the tightness of the structure, fasteners with a rubber gasket are used. Fastening should be done carefully, avoiding deformation of the washer. The fastener itself must enter at right angles into the panel.

Installation of wall panels

In order to properly install sandwich panels, first of all, it is necessary to study the design and installation documentation. It should contain information about the types of products and their layout options. The installation of wall and roofing plates differs from each other. Each has its own nuances of fastening. The cost of installing sandwich panels depends on the amount of work and the thickness of the structure.

Wall plates can be installed horizontally and vertically. The place and order of installation depends on the method. Combining methods is not recommended. Installation of sandwich panels is carried out in accordance with the technology.

In the vertical method, installation is made from the corner by a panel abutting end-to-end, and the horizontal method involves laying the first row from the base.

In order to prevent contact of the product with the structural supports, it is necessary to lay a layer of insulation between them. According to technology, if the length of the panels is more than 4 m, the seam should be 1 cm wide. With smaller dimensions, a seam width of 1.5 cm is permissible. The locks of the panel boards must be connected tightly (especially for vertical installation).

So that the product does not lose its properties, a layer of insulation is laid between them. With the horizontal method, this is done simply due to their own weight. To ensure tightness, silicone sealants are used. Docking seams are protected by overlapping strips. Installation ends with an additional panel.

How much does it cost to install a sandwich panel? Price for 1m 2 :

- with the scope of work up to 1000 m 2 - from 280 to 380 rubles, depending on the thickness of the structure.

- from 1000 m 2 to 2000 m 2 - 260-370 rubles.

Roof Panel Installation Procedure

Installation of roofing sandwich panels is carried out in three main stages. The first is the installation of the first plate and its fastening. Lifting products is carried out using a special vacuum mechanism. In places of tacking, it is necessary to remove the plastic film. The fastening of the first panel is carried out to the rafter or run, which are located near the ridge, and then it is attached to all remaining runs. If the roof slope is more than 12 m, installation is carried out from the overhang to the ridge. After laying, check the correct position.

The second stage is the transverse docking of the product. The bottom end of the next panel is trimmed by attaching it to the run. At the same time, part of the unnecessary insulation is removed. After the expansion is carried out, both panels are connected at the transverse joint. Then a longitudinal locking joint is performed. Before mounting in the groove of the lock, be sure to apply silicone sealant, and then connect the panels.

The cost of installing sandwich panels decreases with an increase in the volume of work.

When installing roofing panels, the following rules should be followed:

- Before laying the product, remove the protective film from the underside. Between the panels and connection elements, the angle of inclination should be 5%.

- To avoid deformation of the locks and skew plate, when joining it is necessary to use two grips.

- When installing sandwich panels, outside the beams or girders, it is necessary to attach a sealing tape.

- The type of fastener, their number and location of the fasteners of one panel are indicated in the design documentation.

Skate installation

After all the roof sandwich panels are installed, you can lay the inner skate plate. The free space is filled with mounting foam. If the mineral wool is the insulation in the product, the cracks are laid with the same material. You can use a special sealant for this. Then, profile polyurethane gaskets are installed, to which a ridge rail is attached from both roof slopes. Then, a polyurethane gasket with an adhesive base is laid again. After that, the ridge bar itself is installed.

The strength of the structure will depend on how correctly and competently the technology for installing sandwich panels is observed. Therefore, when conducting work on their installation, it is necessary to pay attention to the tool, product quality, fasteners and strictly adhere to the technology of their installation. It is best to entrust the installation of sandwich panels to qualified specialists.