Paving slabs (paving stones) are intended for paving sidewalks, pedestrian paths. They use it also in the areas, parking lots of vehicles. Paving slabs are made from durable varieties of natural stone: granite, basalt, diabase.

It withstands high mechanical stress and is more durable than asphalt, as it is not afraid of adverse weather conditions and temperature extremes.

Paving slabs can be of several types. Chipped paving stones with uneven edges are more affordable. Polished tiles are more expensive, but ideal for walking. The choice of material depends on the location of the site. With proper installation, paving slabs will last a long time.

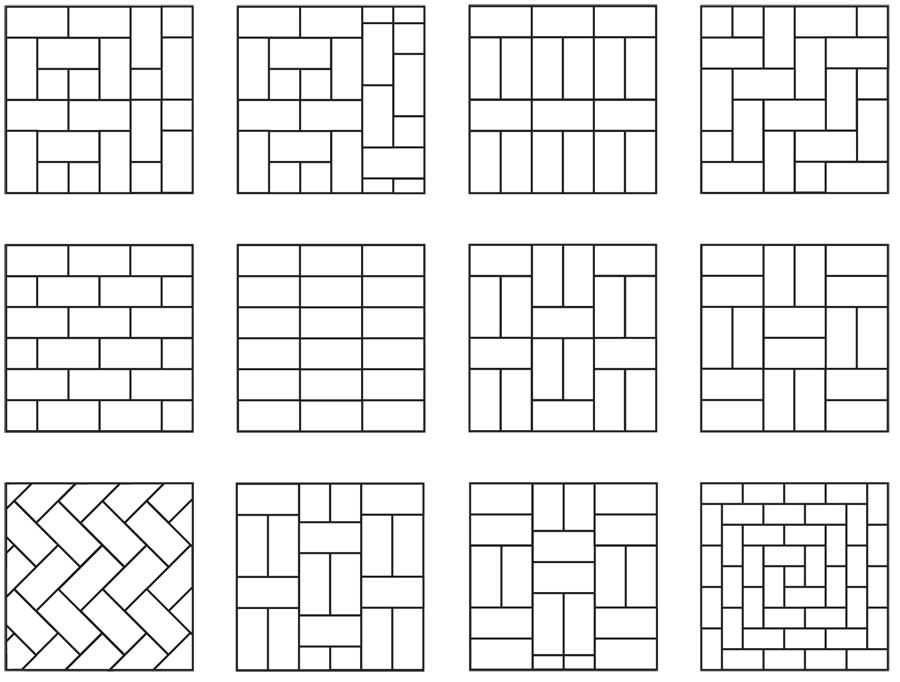

Layout Schemes

Using paving stones, you can create a beautiful design for a personal plot. The most popular patterns for laying paving slabs:

- Mosaic. Hexagon tiles are laid out with a mosaic pattern. With the help of elements of different colors, it is possible to create any ornaments. You can pre-select the picture, practicing with the help of a children's play set.

- Christmas tree. This pattern of paving slabs is the most common. The tile is placed at a right angle or 45 degrees to each other. This method of paving is characterized by high strength, so it is often used in the installation of access roads. Professionals talk about some of the nuances of this method of styling. If the tile is placed at an angle of 90 degrees, the site is visually wider than with the paving method at 45 degrees.

- A brick. Laying paving slabs using such a scheme will save material. This is the simplest drawing, but if you alternate tiles of different colors, the coating will have a very original appearance.

- Chess. The tile, staggered, looks neat and beautiful. The way of laying with symmetrical squares will look spectacular in the design of garden paths of a strict form.

- Rhombs. This drawing of paving slabs has several options. At the same time, you can combine elements of different colors, as well as lay out any pattern on a spacious platform. A classic option is laying tiles in burgundy, white and gray. This type of paving requires preliminary preparation of a schematic drawing and careful marking of the surface. It is this method that allows you to create a pattern with a 3D effect.

- Circular diagrams. The tile is laid in circles, for each of which elements of the same color are selected. This type of paving is used in large areas. They look especially impressive from a height.

- Arbitrary order. In this case, you can use tiles of different sizes and colors. Paving is carried out in random order, but if the owner has abstract thinking and artistic taste, then the layout can turn out to be original and stylish.

- Figured pattern. Paving according to the template is not as simple as it seems at first glance. It is necessary to observe the drawing and the color scheme of the picture. The sample can be the most diverse: leaves, star, flower, animal figure. You can use a sketch created on a computer. For proper laying of paving slabs with the help of a template, careful preparation and accurate marking on the territory is required.

- Under a natural stone. Tile, which resembles natural stone with its texture, looks natural and beautiful on the paths of the garden plot. Paving is done in random order. The material can be combined with wood or pebbles. Tile imitating stone is very appropriate if the facade of the house is decorated with the same material.

Ready-made forms for styling

You can buy similar products today at any hardware store. In this case, it is necessary to choose a really high-quality shape. They are made from a wide variety of materials, and their operational characteristics are significantly different.

Forms are made of polypropylene, rubber, plastic, polyethylene, silicone, polyurethane. You need to carefully consider plastic products, they are often made from recycled materials, so not all of them are of high quality.

You should not acquire forms that have a rough surface and look unattractive. Chips and other flaws, the lack of gloss also indicate a low quality of the material from which the products are made.

When buying, it is important to pay attention to the price of the form. Quality material may not be too cheap. As a rule, the manufacturer does not give a guarantee for such products.

Consider the types of paving slabs that deserve attention.

Silicone

These are the most popular models, high-quality and easy to use. The elastic material allows you to reproduce on the tile even small details of the picture.

The only thing that prevents the introduction of silicone molds in mass production is the not very high strength of the material. As for home use for laying paving slabs in the country, here they are indispensable. The cost of silicone molds is quite affordable.

Polyurethane

Good quality products, strong and durable. Polyurethane molds are well suited for pouring paving tiles with your own hands. Their only drawback is the high cost.

Polystyrene

High quality molds are made from this material. They perfectly convey the texture and pattern of natural stone, are easy to use and durable. These forms do not need to be soaked after pouring, the tile is easily separated from the container during operation. You must be careful when buying, so as not to purchase a fake. In quality forms, the inside is protected by a special film.

Fiberglass

Products from this material are used for laying volumetric slabs in the garden. Fiberglass mold is used for the manufacture of dimensional tiles for garden paths. It can be used in the manufacture of decorative figures and decorations for the country landscape.

It is not very convenient to work with such forms, since in this case preliminary lubrication is required. This can lead to the formation of pores in the molded products, so the tile after removal from the mold must be modified.

PVC

The greatest strength is possessed by PVC products with a thickness of at least 1.5 mm. For containers filled with concrete, special supports and a place for drying are required. Keep the solution in forms for at least two days until completely dry. Such containers withstand up to 70 fillings.

There are film forms made of PVC. Their walls are thinner. These products, filled with a solution, cannot be moved, otherwise they will be deformed. The containers are placed on a stand and filled with concrete.

After use, they are immediately washed in soapy water and dried. This is time consuming, so they are not used for large volumes of work. But even the most gentle care will not make these forms durable; after 20 fillings, they must be replaced with new ones.

ABS plastic

Large concrete elements for wide areas are made from this material. Quality form will never be dark in color. This should be considered when buying. Dark plastic is usually made from recycled materials, so it can burst during deformation.

Rubber

Once such forms were popular when laying paving slabs in the country. With the advent of more modern materials, rubber products are used less and less. These forms are heavy, which will complicate the work with them. In addition, their cost is now quite high when compared with plastic products.

Paving technology

Paving slabs are installed on the base in several ways. All of them are popular, and the choice depends on the characteristics of the territory, soil composition and financial capabilities of the owner of the site.

Laying on a concrete base provides the coating with the highest reliability and durability. This technology is used if a large load on the base is planned. This method is used when equipping parking lots and in storage areas for large vehicles.

Dry mix installation is used for pedestrian roads. This installation process is quite simple, but requires patience and strict adherence to technology features.

Before laying paving slabs in the yard, you must carefully prepare the site. To do this, mark the boundaries of the track, dig a recess of 10-15 centimeters along the entire length. The bottom of the base is covered with a cushioning net, it is necessary to protect the path from germination of weeds. Further, the process depends on the method of paving.

On concrete base

Laying paving slabs on a concrete mortar is more difficult than other technologies. However, it is this method that keeps the paving stones in good condition for many years.

In addition to concrete, it is necessary to prepare geotextiles, sand and gravel for the construction of pillows. A step-by-step instruction for laying paving tiles with your own hands with the help of a solution looks like this:

- First you need to make a pillow. It can be stacked in many ways. The first is to fill the base with sand, then rubble, and then again with a layer of sand. The second - to make screenings of gravel, and then fill it with sand.

- Each layer must be carefully tamped. Between a layer of sand and gravel, geotextiles can be laid.

- Then you need to prepare a concrete solution. You can make it yourself from sand and dry cement, but it is easier to purchase the finished mixture in the store and dilute it with water in the proportions indicated on the package. You should not do a lot of solution at once, as it quickly sets, and the process of laying pavers is quite slow.

- Concrete mortar is poured onto a track or pad. The recommended thickness is 2-3 cm. The mixture is leveled with a notched trowel.

- The next step is the installation of borders. They are of three types: road, garden and trunk. Depending on the place where the paving stones will be installed, use vibropressed curb stone, brick. Large paving slabs can also be used. A groove must be dug around the perimeter of the concrete layer. Cover its bottom with cement mortar with a thickness of 3 centimeters. Do not allow the complete drying of the solution. It is necessary to use a rubber mallet to establish a curbstone around the perimeter of the track.

- The last step is laying pavers. The concrete mortar is laid out in parts on the track and at the same time the tile is installed. The gaps between the elements are filled with concrete.

The finished track is left unloaded for 3-4 days. For travel on it vehicles must be expected at least 25 days.

Dry mix

Dry laying of paving slabs is made on a special mixture, which is sold in hardware stores. Subsequent pouring with water reliably fastens the tiles together and does not allow moisture to pass inside. A step-by-step instruction for laying paving slabs with your own hands on a dry mixture looks like this:

- First, a pillow is prepared from sand and crushed granite. Between the layers laid geotextile. You should not save on materials for pillows. Good drainage will ensure long-term operation of the track.

- Next, dry mixture is poured onto the site and carefully leveled. The layer thickness should be approximately 3 centimeters.

- Then, curbs are installed in the trench on the cement mortar.

- At the final stage, paving stones are installed, they are leveled with a rubber hammer.

- When all the tiles are laid out, the path is filled with water. Getting into the joints between the elements, it passes to the level of the dry solution and concrets it.

Sand laying

Sand is one of the most accessible materials, so this technology is the simplest and cheapest. On the prepared surface lay a layer of sand up to 15 centimeters thick.

For proper laying of paving slabs, the construction of slopes up to 5 degrees is required. They are necessary so that moisture does not linger on the track and does not erode the tile.

The sand layer is leveled, filled with water and compacted. Then, curbs are installed on the concrete solution. Paving stones are laid, leaving a distance of 5 mm between the elements.

The gaps between the tiles are filled with sand, and then the whole track is rammed with a vibrating plate. Correct laying of paving slabs is carried out while maintaining a slope so that moisture does not accumulate on the track. Pavers cannot be paved tight. In this case, she will not hold.

Professional Tips

When purchasing paving slabs, it is necessary to provide for possible waste that is inevitable when cutting. It is worth buying it a little more so that later you do not have to look for identical material.

Excessively bright paving stones do not indicate its quality. The abundance of pigment can adversely affect the strength of the material.

It is not always possible to trim the tiles evenly and clearly. To make the cut neat, it is cut with a grinder, and then chopped. It is not recommended to completely cut it, as it takes too much time.

The preparation of the foundation for paving depends on how the paving stones will be used. For the passage of people, you can lay tiles on a dry mixture. A reinforced concrete base is prepared for the passage of cars.

The choice of tile thickness also depends on the tasks that it will perform. For pedestrian paths, paving stones with a thickness of 4 centimeters are sufficient. To ride a bike you need tiles at least 6 centimeters thick. For cars, paving stones of 8 cm are necessary, and for trucks - 10 cm.

Correct laying of paving slabs is not as difficult as it seems. The main thing is to carefully prepare the foundation and carefully perform all paving work.