The solenoid (electromagnetic) valve is remarkable in that it can be controlled by an electrical signal coming through the wires. The response time does not exceed half a second, which allows the use of such devices as an automated high-speed pipe shutoff valves, working from signaling sensors. But first of all, let's talk a little about the composition and principle of action.

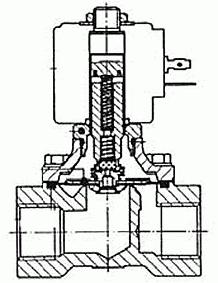

The solenoid valve forms a bronze body with a channel and a solenoid with a divided core in the form of a fixed rod and rod, enclosed in a sealed sleeve. The latter is connected to the membrane via a plunger. A pair of springs controls the smooth running of the moving part. The plunger is most often supplied with an axial hole with a side groove. It equalizes the pressure acting on the membrane on both sides. As a result, the solenoid valve switches with minimal effort from open to closed and vice versa. The solenoid is screwed into the housing with a sealing ring around the perimeter. In this case, the membrane rests on the saddle formed by the fluid flow channel. The upper part of the core contains a fixed element and is equipped with a shielding coil. This is necessary to improve the properties of the

electromagnetic field in the inner space of the liner and prevent vibrations when the device is powered by alternating current.

Everyone, it seems, is familiar with the hum of wires under power lines - this is the result of vibrations caused by alternating voltage. The passage channel is blocked by a membrane with an anchor from the moving part of the core of the solenoid - a wire coil. In the normal state, the passage for the fluid may be free, or may be blocked. Depending on this, the solenoid valve may be:

normally open;

normally closed.

The normal state in this case is the initial one when there is no external voltage. The blocking core is driven by an electric current supplied to the external coil of the solenoid. As soon as the control voltage is applied to the electrodes, the metal rod connected to the diaphragm activates it. Then the path for the medium to flow through the valve is blocked or opens. As soon as the external signal disappears, the system returns to its original state.

The solenoid valve, the principle of which is based on mixing two inlet streams into one outlet or diverting part of the inlet stream, has more than two sockets for connecting pipes.

Depending on the number of inputs and outputs, models are distinguished:

two-way;

three-way;

four-way.

If the first variety is designed directly to work as shutoff valves, then more complex modifications allow you to solve quite specific problems. When certain conditions occur, part of the flow goes down into the branch. Or, mixing of two streams in certain proportions is carried out. A three-way solenoid valve can be used to maintain a given temperature in a hot water or heating circuit. If the temperature is too high, water traffic through the boiler will be blocked. Conversely, a decrease in temperature below a given point will lead to the fact that the bulk of the water will certainly be heated.