Self-made greenhouses from a profile pipe are quite common today. This is due to several reasons, one of which is expressed in ease of installation, and the second in the budget for the work. If you are a thirsty home master, then you can build such a structure without even acquiring material. In order to assemble, you do not need to have special skills, you will only need to follow certain tips. Once the greenhouse is ready, it will not have to be maintained, and if a durable variety is chosen as a covering material, then the greenhouse will not even have to be dismantled for the winter. Unlike greenhouses, which are based on other types of wood-based materials, the steel structure is durable, in addition, its elements are not able to infect rotting processes, and fungal damage to the plant is not terrible. Greenhouses of this type are resistant to deformation, which can be caused by elevated temperatures.

Varieties of forms of greenhouses

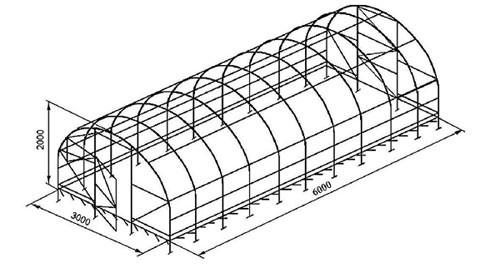

The most often built arched greenhouse from a profile pipe with their own hands. It is suitable for growing low plants in its space. One of the features of such a greenhouse is the ability of the roof to self-clean. After all, debris, as well as rainfall, will constantly fall on the surface. The shape may also be tunnel. Such installations have standard sizes. Thus, its height is limited to 5 m, while the width is 10 m. If there is a need to grow tall plants, then it is worth choosing a tunnel shape for construction. If strong winds prevail in the construction area, then such a greenhouse will endure them steadily.

Do-it-yourself greenhouse from a profile pipe can be made. If you choose this form, you can set a rather high design, inside which you can move in full growth. This form is used for growing greens, mounted on supports, as well as upright and climbing crops. If there is a need to distribute the area of the site rationally, then it is worth choosing this form. Sometimes a pyramidal shape is also used in construction; a greenhouse of this type will also take up little space.

Determining the location for the installation of the greenhouse

Before you start building a greenhouse from a profile pipe with your own hands, you need to determine the place where it will be installed. Among the main features of the installation site, you can highlight the presence of a sufficient amount of light during the day. You should not start work if there are tall trees nearby that give a shadow. It should be noted that there should be a convenient approach to the greenhouse in order to be able to bring water and fertilizers into its internal space.

If you plan to build an elongated greenhouse in shape, then it is preferable to arrange it from east to west. When constructing a structure with a gable roof, a sash intended for ventilation should be located on the southern slope.

Preparation for construction

For a greenhouse from a profile pipe with your own hands, you need to prepare pipes that will form the basis of the frame. The diameter of these elements should be limited to 40x20 mm, it is precisely such blanks that will be able to provide strength and stability. But in the manufacture of a bundle between frames, it is necessary to use pipes whose cross section is 20x20 mm. Initially, it is necessary to prepare a design diagram. If there is a need to build a greenhouse, which will have a more impressive usable area, then it is worth using a semicircular frame, rather than a gable, but if you decide to choose it, you will have to stock up on a pipe bender. Its cost is quite impressive, so it is not advisable to purchase it for the manufacture of one greenhouse. Well, if there is an opportunity to rent such equipment.

Parameter Definition

Before making a drawing for a greenhouse from a profile pipe with your own hands, it must be taken into account that the frame must have a length of 6.05 m. This parameter is due to the standard size of the pipe sold in stores. As for the height, it is necessary to stop the selection by 1.7 m. This indicates that the profile will need 3.4 m. A piece of 2.65 m will remain from the length of the segment. If we take into account the angle of inclination of the roof slope, then, as a rule , the angle is 30 0 , but the width will be 2.24 m. If you remove 24 cm from the resulting width, this will allow you to cover the structure with a standard polycarbonate sheet, in addition, overhangs will be left on the sides for water flow.

If you prefer just such a greenhouse, then this will do without tools, the cost of which is high.

Foundation design definition

Before you start building a greenhouse frame from a profile pipe with your own hands, you need to take care of the foundation. Options for its construction may be different. The basis can be materials that can be found on the site, it can be a railway sleeper and even a grillage made of screw piles. But the most popular among summer residents is the foundation, built on the basis of concrete. In this case, the design will be shallow. Lay the foundation on one bayonet shovel.

Foundation construction

Before pouring the foundation, it is necessary to carefully level the site and prepare the pit. After the perimeter, it is necessary to lay the anchor for the installation of profile pipes. The next step will be to prepare a solution, among the ingredients of which will be pebbles, sand and cement. The prepared mixture can be poured into the pit and left in this state until the solution sets.

Work on mounting the frame

The next stage involves the manufacture of a greenhouse from a profile pipe with your own hands, which indicates the need for assembly of the frame. For this, a profile with a cross section of 40x20 mm is to be welded to this. This design will act as a reliable basis for fastening auxiliary and main frames. In order to avoid distortions, the installation of frames should be carried out on a smooth and durable surface. If you need to perform a cut, do not rush to cut the entire segment, initially you should only make an incision in the bend area. After that, it is recommended to bend the pipe so that it is possible to get the frame of the desired configuration. Then you can begin to weld the joints on the workpiece, which must first be assembled.

When working, a greenhouse scheme from a profile pipe should be used, it is not difficult to make it yourself. It is worth remembering that the end frame acts as an important supporting structure, it is necessary to mount a door and a window in it. It is recommended to do this on a frame that is previously laid on the site. The door frame must be welded from a pipe, the cross-section of which is 40x20 mm, with regard to the window, it will have to be made from a 20x20 mm profile.

It is necessary to take into account the width of the polycarbonate paintings, which is 2 m, this will determine the distance between the arches. The length should be selected so that the joints are on the profile pipe. With frame pipes 40x20, a step of 1 m can be ensured. The frame frames must be mounted at a distance of 1 meter, after which they must be strengthened together with 20x20 pipes. Why do the segments should be welded flush with the main profile. This compound helps to cover the greenhouse with an even layer of material.

Mounting frame elements

A do-it-yourself scheme of a greenhouse from a profile pipe should be prepared in advance. The vertical assembly of the elements should begin with the end frame with the door. In order to ensure accurate mating with the vertical plane, it must be strengthened by the braces of the corners, which must be welded to the horizontal pipe of the base. A horizontally positioned bundle of profile pipes must be mounted indented 10 cm from the inflection of the frames, which will allow polycarbonate to be well fixed in length and width.

Shelter Mount

In the work it is necessary to use the drawing of the greenhouse from the profile pipe, with your own hands it will turn out to produce a better assembly. At the last stage, it is necessary to strengthen polycarbonate, it is necessary to do this using self-tapping screws 3.2x25 mm with a washer.