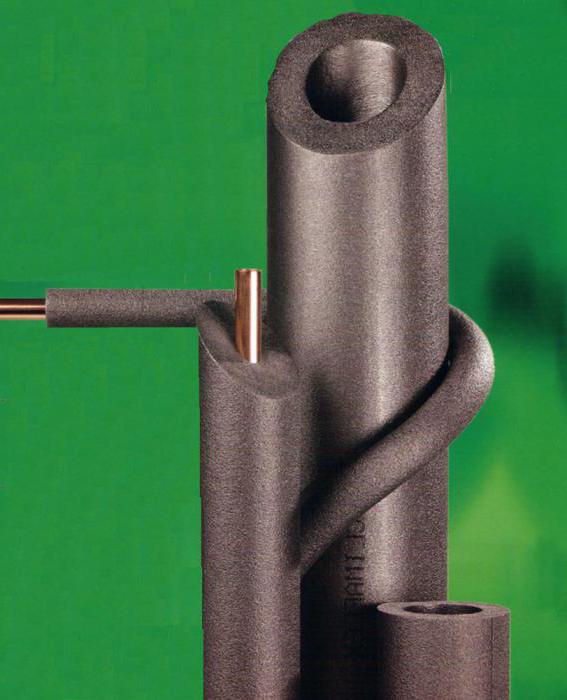

Pipe insulation made of foamed polyethylene is a material that has high flexibility, as well as resistance to various kinds of mechanical damage. This protection is not afraid of the effects of gypsum, gasoline, oils, as well as lime. The surface is able to undergo a coolant temperature, which can reach 90 degrees. The insulation has the form of tubes that are installed on the main pipes of the system by simple tensioning. If the pipe insulation is mounted on an already installed system, it will be necessary to make a cut along a special longitudinal line. The resulting seams should be glued using a composition developed for these purposes. Due to the longitudinal section of the tube, it is possible to cut not only smoothly, but also quite simply, providing quick and quick installation. The excellent characteristics of the described insulation can save on heating, as well as reduce the final weight of structures, reducing the consumption of building materials.

Key Features

Pipe insulation is made by extruding polyethylene granules. As a result, it is possible to obtain a structure that has small closed pores. The material contains a significant amount of air, which ensures thermal insulation qualities. Products have high elasticity and flexibility. On sale you can find many sizes, while the length of the tubes is two meters. The color of the tubes is gray, and there is an assembly cut along the entire length. The pipe insulation of the type described can be used for pipelines made of steel and copper.

Appointment

Products are used to protect cold pipelines that are located inside the structure. In this case, the prevention of condensation acts as an insulation function. It is worth noting that the latest phenomena can cause a reduction in the life of the pipeline. Isolation is also used in freezers when there is a need to keep the carrier temperature extremely low. Quite often, these products can be found in the arrangement of hot water systems, which are located inside structures. In this case, the preservation of the initial temperature also acts as a task. If insulation is used outside structures, it can prevent freezing. Among other things, this material can protect a person from the possibility of getting dangerous burns. Indoor operation is allowed without additional recommendations, while it is necessary to install insulation from the outside, protecting it from direct sunlight. In this case, the material can undergo exposure from -40 to +70 degrees. Humidity is allowed up to 100%. The temperature of the coolant in the pipeline can vary from -40 to +100 degrees.

Advantages of using

If the Thermaflex pipe insulation will be used , then you can be sure that the material is absolutely hygienic and safe for human health and the environment. It is completely inert, does not form dust and does not have a foreign smell. You can use it in objects for various purposes, up to medical institutions and buildings of the food industry. This type of insulation is completely impervious to steam and water. It prevents the occurrence of fungus and resists decay. In addition, it is not necessary to protect the insulation, among other things, it is able to prevent corrosion, as well as the effect on pipes of concrete, cement, lime and gypsum mixtures. Thermaflex pipe insulation reduces acoustic noise and reduces structural sounds that may occur during operation in the system. Installing products is quite simple, in work they are economical in terms of labor costs, which is very to the liking of modern consumers. Such insulation is characterized by durability, its life span is much longer compared to that possessed by the pipeline itself.

Installation Features

K-Flex pipe insulation must be installed after the surface has been well cleaned of contaminants such as grease and rust. Work should only be done on non-functioning equipment. It is necessary to provide blackout 24 hours before the start of installation work. If necessary, you can cut using a sharp knife. When laying, it is important to ensure absolute tightness. To do this, use special glue "Energoflex".

Installation on an uninstalled system

If you will use the Energoflex pipe insulation, which is installed on a system that has not yet been mounted, you must put the pipes on the pipes. When welding, be sure to protect the material from penetrations. After the seams have cooled, they should be cleaned and the insulation material advanced on them . At the final stage, the insulation is glued together at the ends. Joints can be made using building brackets. In order to provide additional sealing of the joints, reinforced tape can be used . If the pipeline will be in the ground during operation, then it should be protected by a casing, which will eliminate damage caused by soil elements.

Pros and cons

Pipe insulation made of polyethylene has an insignificant coefficient of thermal conductivity, this indicates that the material is able to provide effective performance of its tasks with a small thickness. The described insulation has a fairly impressive mechanical strength to tensile forces, which is why, after deformation, the material restores its original shape quite well. Use during installation does not need additional tools. One of the important advantages of this heat insulator is the low cost, which is almost half as much as that of analog materials. This makes foamed polyethylene cost-effective for work on large pipelines. However, there is one single drawback. It is expressed in flammability. This makes it impossible to use this insulation at facilities that have high fire safety requirements.

Specifications

K-Flex ST pipe insulation has a density that can vary from 25 to 40 kg per cubic meter. Among other things, one can distinguish excellent elasticity, which remains up to -80 degrees. This allows you to use this material on any pipe, whatever form they may have. The highest tensile load that this insulation can withstand is 0.3 MPa, while the insulation has a dynamic elastic modulus, which is equivalent to 0.77 MPa. As for the compression ratio, which is maintained under external load, it is 0.2. If you will be purchasing Rockwool pipe insulation, then you need to pay attention to the thermal conductivity coefficient, as a rule, this figure varies within 0.035 W / micron. As for the vapor permeability coefficient, it is equal to 0.001 mg / MchPa. It is according to this indicator that the described insulation can be attributed to the class of materials that are completely vapor tight. Pipe insulation made of foamed polyethylene absorbs water in an amount of 1.5% of its volume after being in water for a day. This indicator increases by tenths with increasing time of exposure to water. Thus, if you put the insulation for 28 days in water, then it absorbs 1.9% of its weight.

additional characteristics

The thickness of the material can vary from 6 to 20 millimeters. In this case, the intermediate values are 9 and 13 millimeters. On sale you can find a wide variety of standards for the diameter of the sleeve, this parameter ranges from 12 to 200 millimeters. In industry, the most commonly used internal diameter is 100 and 150 millimeters. In the production process, in addition to the foamed reagent, all kinds of special additives are added to the ingredients, which are designed to give the final product the required characteristics, namely elasticity and fire resistance. As for the latter, the insulation is classified as moderately combustible.

Conclusion

If there is a need to prevent condensation from occurring or to protect pipes from corrosion processes, the pipe insulation described above should be used. By purchasing this material, you can not be afraid that it will be able to do harm. This is due to the fact that this kind of insulation is made from environmentally friendly ingredients. It is for these reasons that in modern industry and when arranging private pipelines, a heater of the type described above is used, which is inexpensive and has truly outstanding qualities.