After the construction of the house is completed, it is necessary to arrange a blind area. If this is not done, precipitation flowing from the roof and walls of the house is delayed, contributing to the subsidence of the foundation. To protect the building from moisture and prevent its accumulation in the basement area, materials are used that have special water-repellent properties. The waterproofing of the blind areas is necessary to perform the following functions:

- protection of load-bearing structures, basements and basements from water;

- decrease in soil moisture near the foundation improves its heat-insulating properties;

- prevention of soil heaving ;

- protection of the foundation from the destructive action of the roots of perennial plants;

- coatings give the structure a decorative look.

A fertile layer of earth is removed to the size of the blind area , which is about 25 cm deep. Its optimal width is 100 cm. The blind area around the house is waterproofed around the entire perimeter, no matter what material is used. If the overhang of the cornice extends over a long distance, the blind area should be wider so that water flows down onto it.

Waterproofing for the blind area: material

- Roll materials also suitable for roof protection: geotextiles, ruberoid, hydroglass glass, polypropylene, rubemast.

- Liquid - for the treatment of foundation surfaces and waterproofing joints: bituminous mastic, tar, compositions absorbed into concrete.

- Solid materials: asphalt, concrete, cobblestone, paving slabs, artificial stone, etc.

Types of bulk blind area

The simplest waterproofing of the blind area is done using clay. It is laid out around the house with a slope outward, rammed, and then covered with other materials, for example, gravel, so that it is not washed out by water.

Depending on the purpose, the following types of waterproofing blinds are used.

- Bulk . Consists of two layers. A layer of crushed stone with a thickness of 10 cm is placed above the lower layer of rammed clay (20 cm thick). The type of waterproofing is the simplest. It is used when draining water from the roof using a drain and in areas with little rainfall. On such a blind area it is inconvenient to walk. It can also blur over time when the clay gets wet.

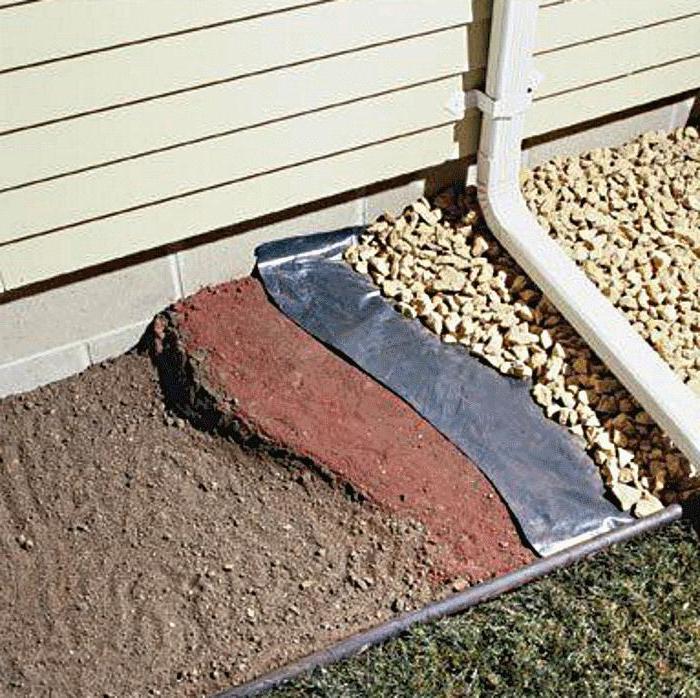

- Bulk with additional waterproofing protection. The blind area is made more complex. Suitable for protecting basement houses. Rolled waterproofing for the blind area is laid on a layer of rammed clay with an overlay on the foundation, and then it is covered with gravel or pebbles. So that the layer is not loose, a layered “cake” is made: clay, a waterproofing sheet, a 5 cm layer of coarse sand, a geotextile, a 10 cm thick gravel layer, a geotextile and a 10 cm gravel layer. For complicated blind areas, it is advisable to use durable materials based on polypropylene, PVC films, etc.

Soft bulk blind area is increasingly used in connection with the appearance of high-quality facing materials - paving slabs, artificial stone, etc. They are laid on a layer of sand, comfortable and durable.

Asphalt or concrete blind area

Solid waterproofing of concrete or asphalt pavement is a reliable protection against precipitation. A deepening of 25 cm is made in the soil around the house. The bottom of the trench should be carefully tamped. Then the formwork is constructed for concrete pouring. A 10 cm thick sandy layer is placed in the trench. It is wetted with water and rammed. A 5 cm thick layer of crushed stone is poured onto the sand, which is also compacted. The road mesh for reinforcement is laid on top.

Concrete mortar is preferably poured in one step to provide the necessary strength. After the surface is leveled and a slope of 5-10 0 is made as a rule. After the initial hardening for two hours, the blind area is closed with a film for 2 days. This is necessary to maintain moisture, contributing to an increase in the strength of the layer. The coating can also be asphalt.

Concrete blind area can be laid out of the finished slabs. It has characteristics similar to aspic. Nowadays, laying pavers or paving slabs is widely used. To do this, crushed stone is poured onto the clay waterproof layer, then sand, and a hard coating is paved onto it.

Waterproofing and drainage

To drain water along the outer edge of the blind area drainage is done. Here you can pave stone grooves. The bottom is waterproofed. You can simply saw along and lay out an asbestos-cement or plastic pipe. It is performed with a bias to the drainage well.

You can use ready-made channels or trays for drainage with gratings on top.

The budget solution is the use of closed drainage. To do this, geotextiles are laid in the drain, which is filled with gravel, and then wrapped on top with the same fabric and covered with sand. Waterproofing under the blind area and drainage is done as a single unit, so that the water does not go into the ground.

Features waterproofing blind areas

- Waterproofing is chosen taking into account climatic conditions, soil conditions, the presence of groundwater and the peculiarities of the location of the house.

- Waterproofing blind areas around the house can be made at different levels. In many cases, a concrete screed is sufficient. But it may be necessary another level of home protection using roll waterproofing. It is imposed with an overlap on the foundation with a height of 15-20 cm.

- High-quality home protection is provided by covering the foundation with bituminous mastic, and then applying roll insulation to it. If it is done in several layers, each of them is glued to the walls with mastic.

- The blind area is made on the basis of waterproofing cements. They can be bred independently by adding additives.

Penetrating foundation insulation

Waterproofing of the foundation and blind areas is done in the complex. The modern method is the processing of concrete surfaces with penetrating compositions containing Portland cement with fillers and active chemical additives. To do this, open the pores of the concrete with the removal of weak fragments. The surface should be moistened before processing, but not excessively, otherwise the material will erode (not more than 5 liters of water per square meter). When breeding material, all points of the instruction must be followed. It is important that the impregnation is appropriate for the type of surface. It is applied evenly. Thin layers will not perform their functions properly, while thick ones will crack. Closing holes here is ineffective, since the tool is designed to improve the waterproofing properties of concrete itself. The protective composition fills the pores without passing moisture.

Conclusion

Anyone who does not have the professional skills of a builder can make a blind area. At the same time, it must be done correctly in order to reliably protect the foundation from precipitation. The waterproofing of the blind areas is especially important.