The reinforcement method is often used in construction. This is due to the fact that the often used material in construction - concrete, having high strength, also has an unprofitable property - brittleness, that is, it does not have elasticity. With uneven loads, vibrations, temperature extremes, in large structures it would be impossible to use concrete without reinforcement. It would just crack, crumble and crumble.

What is going on?

What forces act on the structure? We will understand, without delving into the plots of sopromat. Under load or vibration, each part of the structure accepts and resists, as long as there is enough strength. For example, take the ceiling of the first floor, it is the floor of the second floor. When loading from above, the beam resists bending downward.

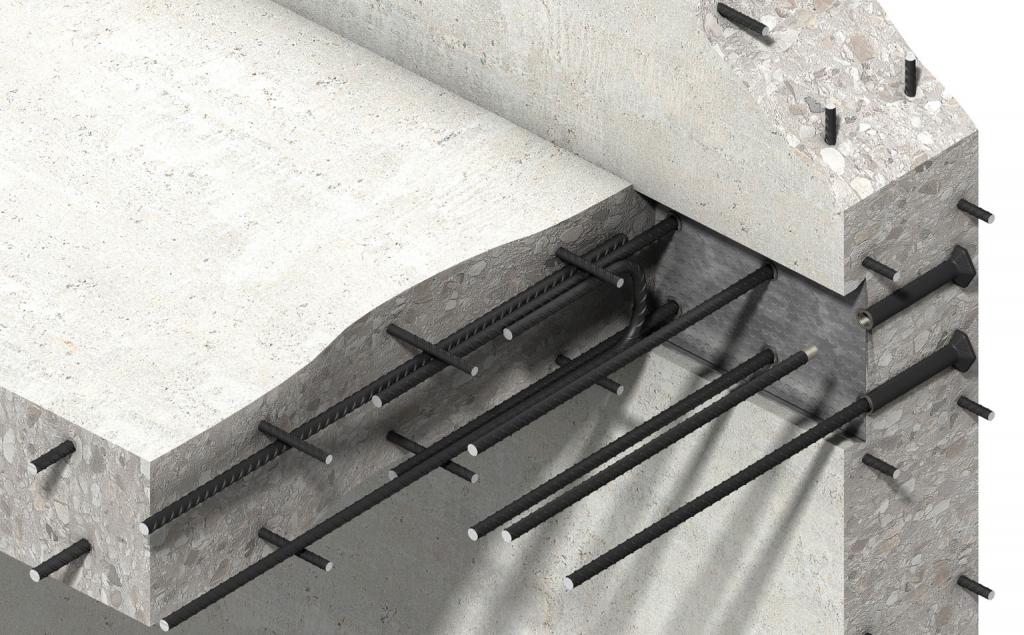

In this case, the upper part of the beam experiences a compressive force, and the lower one experiences a tensile force. Due to the fact that concrete can withstand more compression force than tensile strength, in our case, if the beam is not reinforced, then concrete will collapse faster at the bottom of the structure. First, cracks in the lower part will go, and then the structure will crumble. To prevent this from happening, they make reinforcement of the beam. The point is to quench the tensile and compressive forces due to steel reinforcement or wire. The first has a high degree of tensile and compression resistance. Therefore, before pouring concrete, a double mesh of reinforcement is made. The first layer of the mesh is placed below (10-50 mm from the lower surface of the beam), the second above (10-50 mm from the upper surface of the beam). The distance between the upper and lower mesh will depend on the thickness of the structure.

Concrete pouring with reinforcement

The work is not particularly difficult. Everything is extremely simple and comes down to four stages:

- Formwork, assembly and installation.

- Reinforcement.

- Concrete preparation.

- Fill.

First you need to prepare a site where concrete will be poured with reinforcement and formwork. The area of the plot should be as even as possible. Next, you need to prepare materials, calculate the amount of sand, cement, gravel, reinforcement and ready-made concrete. The filling starts from the foundation and is carried out from the lower to the upper sections.

Formwork

Reviews say that the most critical part is the assembly and installation of formwork. In fact, this is a fence made of boards, plywood or metal sheets. Such a structure is easy to build with your own hands. Its task is to give concrete a certain shape. The formwork should have a flat, smooth surface, all parts should fit snugly against each other so that there are no gaps, gaps, protrusions. The more even and better the formwork will be assembled, the less work and materials will go on plastering and finishing. The most popular formwork material is laminated plywood sheets with a thickness of 16 to 24 mm. The thickness is selected depending on the area of the structure. Plywood is easy to cut, using a jigsaw you can give the most complex configuration. Plywood has a fairly flat and even surface, and due to lamination it is easily removed or moved from the hardened concrete. After removing the formwork from one site, these same sheets can be used for the manufacture of other concrete structures. All cracks after assembly are filled with mounting foam. After the foam hardens, it is necessary to cut off all unnecessary bursts inside the formwork. Otherwise, there will be voids in the concrete structure that will have to be repaired during decoration. The internal dimensions of the formwork, its shape at all levels must comply with the design. When everything is assembled, foamed and cleaned, you can proceed to the next stage - reinforcement.

Formwork for columns, "deck"

When pouring columns, mobile formwork is used. That is, they make it by the thickness of the column, say a meter high. After pouring and hardening of concrete, using 4 jacks, the formwork is moved up without disassembling, and the next layer is poured. This method is good if there are a lot of columns in the structure. This saves time on assembly and disassembly.

The construction of the formwork in the horizontal plane, the builders call the "deck deck". The peculiarity is that first they install vertically adjustable racks, at a distance of 1.5-2 m. Planks with a thickness of 50-60 mm are placed on the racks, on them are sheets of plywood (with the laminated side up). It is also important to ensure that there are no gaps, and the sheets fit snugly against each other.

Reinforcement of horizontal structures

Reinforcement is performed in two ways. The first is a finished iron mesh for concrete reinforcement. Suitable for not very large loads. The mesh is pulled over the formwork and secured with wire through the holes drilled in plywood. Adjustment gaskets are installed at the attachment points. This is necessary so that the grid does not touch the formwork. Otherwise, after removing it from concrete, parts of the mesh will be visible, which will then rust, collapse and spoil the appearance of the structure.

The second way is wire-wound fittings. Judging by the reviews, this design can withstand heavy loads. All work is carried out without welding. Metal rods are laid out parallel to each other, at the same distance, and then, directly on them, the rods are laid out perpendicularly so that they intersect at right angles. The laying pitch varies. All intersections of the rods are connected by knitting (soft) wire. As well as for a grid, adjusting laying is applied. After linking the bottom of the net, similarly make the top. Between the upper and lower planes of the grids, support legs are also installed. Usually they are made from reinforcing bars, which are welded between the first and second layer at certain intervals. The latter are calculated so that the rods do not sag under their weight, the flatness of the structure is ensured.

Reinforcement of concrete wall, columns

For walls, a grid of reinforcing rods can be connected in a horizontal plane, and then be raised and fixed in a vertical. But with large volumes it is more convenient to knit the mesh in an upright position. When concreting walls, the net is first knitted, then spacer sleeves are installed (to adjust the wall thickness).

Usually use spacers made of plastic or plastic. Because after removing the formwork, they will remain in concrete, and the plastic or plastic bushings will neither rust nor decompose. After their installation, formwork elements are installed. Opposite parts are connected with metal screw pins that pass through spacer sleeves. They do this so that the studs do not come into contact with concrete. Then the stud nuts are tightened, thereby pressing the opposite parts of the formwork to the spacer sleeves. The side parts of the wall are attached to the front parts using clamps or clamps.

Reviews note that when reinforcing vertical structures (whether it be walls or columns), reinforcing bars should be higher than the surface of the filled area. They do this so that this section can be connected with the horizontal filling section. As a rule, the latter (the highest filling area) has a horizontal plane.

Concrete preparation

The main guarantee of the quality of the prepared concrete mixture is the exact observance of the proportions of all components. It is important to pay attention to the brand of cement used. Different grades of material correspond to different volumes of sand. The hardness of the water should also be considered. If it is fundamentally important to achieve maximum concrete strength, it is better to check this figure in the laboratory before preparing the mixture. In practice, they reduce the hardness of water using the most common detergents (the most budget option is a dishwashing gel).

It is very important to follow the sequence. First, water is poured into the container, then cement, crushed stone and finally sand. For small volumes use hand tools or small automated ones. For large volumes use special machines.

Pouring

An equally responsible part of the work is pouring. Before it, you should once again check the tightness of the formwork, the presence of extraneous holes. The formwork should be greased with waste machine oil or any other greasy mixture so that it is easier to dismantle it. Spread concrete mix so as not to displace the reinforcing mesh. After pouring, you need to carefully walk with a vibrator to compact the concrete along the entire plane of the filled area. This is necessary so that voids do not form, especially for complex configurations where air could remain in pockets.

Conclusion

The key to success in construction is the accurate execution of all operations, compliance with sizes, calculations. All work at any stage requires attention, knowledge and skills. If everything is calculated correctly, and the work is done efficiently, then the design will be strong and durable. As an alternative to classical reinforcement, fiber concrete exists. The essence of reinforcing concrete with fibers is that the latter, by their nature, are able to absorb higher stresses than a concrete matrix.