Adhesive is a mixture or substance, as well as various multicomponent compositions made on the basis of both inorganic and organic substances popular today. He is able to combine a variety of materials: paper, fabrics, leather, wood, ceramics, glass, rubber, metals, plastics. Bonding is caused by the formation of an adhesive (very strong) bond between the joined surfaces and the adhesive layer. The strength of the adhesive joints is also affected by cohesion to the surface of the adhesive. According to the type of bonding, adhesives are classified into drying, non-drying adhesives and adhesives, which are based on polymerizable compositions.

Consider the drying form (its characteristics), namely carpentry glue. It includes: casein, glutin, PVA, vegetable adhesives and adhesive masses from synthetic resins.

Casein wood glue is a brown-yellow powder. It is made from alkali and dry skimmed cottage cheese. When cooking, this powder is poured into non-cold (room temperature) water and constantly stirred.

The ratio is 2: 1 (water to powder). In its properties, it is inferior to fish, but it surpasses the skin.

Joiner's gluten glue is made from mezdra (animal skins, tendons, cartilage), fish and animal bones. It is divided according to the types of substances that underlie it: bone, fish and skin. Fish is mainly used for various

restoration works, and bone and skin ones, as a rule, when working with furniture. Most often, gluten carpentry glue is produced in the form of small dry tiles. Sometimes it happens in barrels, but in this form it quickly rots. It is advisable to prepare the adhesive solution for one to two days. It is important that the residues are stored in the cold. The quality of the tile is determined by the external state - if it does not bend, when broken does not give sharp edges and has a transparent color, then this is a good tile. And vice versa, the dark color of the tile, the chipped edges and the ability to easily bend it indicate low quality. Preparation: tiles must be poured with boiled water, cooled to 25 degrees, and wait 10-12 hours until they swell. If you previously crush the plates into pieces, then you can reduce the swelling time to 2-4 hours. Swollen glue needs to be boiled for three hours. In order to avoid rotting of glue it is possible to add antiseptics when cooking. When gluing, the surfaces are first smeared and given exposure (5 minutes). Then the parts are connected and wait another 5 minutes. After placed for a day under the press.

Joiner's

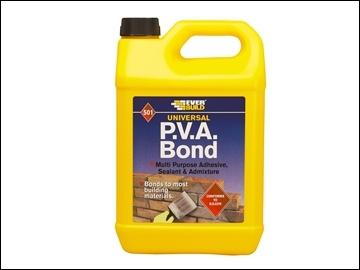

PVA glue is available in tubes ready for use. It is not washed off with water, dries quickly, but unfortunately has a short shelf life. Despite this fact, at the moment it is the most common among other species.

Vegetable wood glue is not widely used due to weak bonding properties. For the most part, it is made from starch and is used for bonding cloth and wooden surfaces.

The adhesive masses of synthetic resins are liquid and pasty. They are suitable for wood, and for cast iron, and for porcelain. They are most often made from carbinol.