The conditioning process involves changing or maintaining certain parameters of the air environment. This can be a correction of humidity, temperature, flow velocity, purification, etc. For automatic regulation of these and other parameters, an air conditioning system is used, which is a complex of technical units and assemblies.

The principle of operation of the equipment

There are many options for the structural design of the unit, but the basic set of functional units remains the same. For the full operation of the air conditioner, the interaction of the compressor installation, evaporator, condenser and thermostatic system is required. In the complex, these components form the conditions for a kind of processing of air flows. The active element for maintaining the functionality is a refrigerant circulating through a closed sealed system of copper pipes. These circuits connect the aforementioned units, closing on the heat exchanger.

As a rule, the role of the refrigerant is performed by freon. Since an active mixture of this kind is not environmentally friendly, special cylinders are used for its storage. If we are talking about split systems, then the tanks are located in the outdoor unit from the street. During the operation of the ventilation and air conditioning system, the coolant circulates through the pipe connecting the compressor and other functional units. This circuit is called refrigeration, but it also serves other tasks of changing microclimatic parameters.

The residual product of the work process is condensate. Its formation is inevitable, since it naturally arises as a result of the dilution of the refrigerant. Therefore, in most designs of air conditioners, you can observe a drainage channel - a drainage pipe through which the accumulated condensate already flows into the ground in the form of water from the side of the outdoor unit.

Functions Performed

In most cases, the key task of an air conditioner is cooling. That is, lowering the temperature to a comfortable level. Accordingly, such units are more often used in the summer. The permissible peak mode in terms of temperature tolerable by the equipment is +40 ... + 50 ° C, and in winter it is not recommended to turn on the units at an average of -25 °.

And here it is worth noting different approaches to air conditioning, implemented by classic and inverter models. The former regulate the temperature stepwise, turning on and off the circulation of the refrigerant as needed. The second principle, a more modern inverter, involves constant monitoring of the microclimate with a smooth change in its individual parameters. As a result, the absence of energy costs for turning equipment on and off allows saving on electricity.

The second most popular feature is ventilation. The movement of air flows is implemented by mechanics, represented by built-in coolers and fans. Unlike changing the temperature parameters, ventilation and air conditioning in the complex can use street air. As for the heating function, it is used less often, since the basic structure of such equipment is not designed for the integration of heating elements. Nevertheless, there are multifunctional air conditioning systems in which the heater block is also implemented, although with a small capacity.

Varieties of air conditioners

There are many classifications of this equipment, and they affect various aspects of the structural device, the principle of operation and operational characteristics. The most pronounced differences of different types are represented by the following aggregates:

- Central systems. Industrial equipment that requires not only electricity but also heat resources (hot water, steam, etc.) to maintain operability. Due to the high power, the central units provide ventilation and air conditioning in large rooms - in factories, in halls, salons, stadiums, etc.

- Split systems. The most common concept of office equipment, which is characterized by ease of installation, ergonomics, compactness and attractive design. In turn, split systems can be floor, wall, cassette and ceiling.

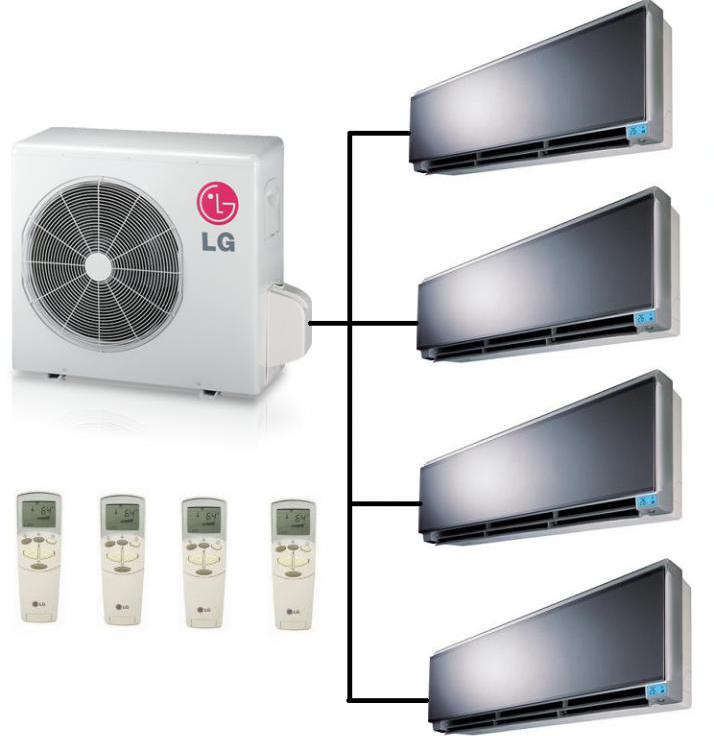

- Multi-systems. The features of this equipment include the possibility of optimized maintenance of several zones from one compressor unit. The outdoor unit is installed in one place. It can connect working air conditioners in different rooms. This is a convenient concept if you plan to serve 10-12 different rooms with one exit to the outside.

It is worth noting the classification according to the nature of the provision of meteorological conditions for air conditioning - SNiP 2.04. 05-91 provides for the division of equipment into three groups:

- Units that comply with regulatory documentation in terms of maintaining process parameters. Used in industries and in public buildings.

- Air conditioners providing optimal sanitary and hygienic indicators or established technical standards. Are applied in the household sphere.

- A kind of auxiliary systems that are used in cases where the local communal infrastructure does not provide adequate ventilation intensity without artificial cooling of the air.

Equipment performance

From the point of view of the end user, of course, the main thing is the temperature ranges over which adjustment can be made. For example, in domestic air conditioning installations, the lower threshold varies from -5 to +15 ° C, and the upper reaches +45 ° C. In the heating mode, the equipment can work in the range of -5 ... + 20 ° , but, again, this applies to a narrow segment of units.

Climatic equipment is known for its high energy consumption, which is due to the considerable power and performance of the electric motor. Indeed, for household appliances, 5-10 kW is a significant potential, but only with its help it is possible to maintain effective regulation of the same temperature in a constant mode. By the way, for urban apartments with a small area, it is quite possible to limit yourself to buying devices with a capacity of 2-3 kW.

Among the negative operational factors of climate systems, noisy work is often noted. Indeed, at a hearing threshold of 0 dB, sounds at 25 dB can be uncomfortable. And then, this applies to the indoor unit, and an external compressor during air conditioning can operate at 40 dB. However, manufacturers are increasingly providing equipment with "night" operating modes, in which the noise reduction function is activated against the background of optimization of electric motor resources.

As for dimensions, no standards exist in this regard. The only rule in force is the direct relationship between size, weight and power. By the way, the mass is in this sense the most responsible factor of choice, since heavy equipment on a flimsy cladding with weak fastening can simply collapse. The average weight of the kit is about 30-50 kg, which is also a lot for a household unit, especially if it is ceiling or wall.

Air conditioning design development

The technical document describing the system parameters includes several sections that reveal the characteristics of the equipment, functional requirements, installation recommendations, etc. At the household level, this task can be performed in the process of determining the target area for air conditioning, the possibilities for the location of the optimal design and the requirements for unit operation. In particular, the zoning of the system, its coverage and the length of communications are determined.

At this stage, it is important to evaluate the connectivity. As a rule, split systems operate on single-phase 220 V networks, and industrial systems require 380 V loads. In terms of communications, the design of air conditioning systems provides for the installation of boundaries along the maximum length of trunk lines. This also applies to pipes through which the refrigerant circulates, and electrical cables. So, the length of the refrigeration pipes can vary from 5 to 70 m. In the first case, we are talking about household split systems, two blocks of which are separated by a normal wall, and in the second, the distance to tens of meters can be taken into account for multi-systems covering several working blocks premises in one building.

Calculation of an air conditioning system by power

As already mentioned, the power potential of air conditioners can be both 2 kW and 10 kW, and industrial systems even work with engines up to 15-20 kW. Of course, for a small house there is no need for high performance - in addition to excessive energy consumption from such a regulator, you will not have to wait. Therefore, for reasons of rational operation, the optimal power load should be taken into account in advance.

It follows from the fact that a room with an average area of 10 m2 will require 1 kW for cooling. This is provided that the ceiling height of the room does not exceed 3 m. A small addition is also made if there are several other electrical appliances in the room that will complicate the air conditioning process due to its own thermal energy. A finer calculation for each “square” is also possible. For example, 1 m2 corresponds to 100 watts of cooling capacity. This approach justifies itself in cases where there are problem areas in the room - for example, near a window with direct sunlight. In any case, in order not to miscalculate in the calculations, it is worth adding another 10-15% of the power to the displayed figure. At least, an excess in the performance tolerance will allow to level the operating modes of the equipment.

Installation of air conditioning systems

First of all, the indoor unit is installed. If the most common wall system is used, then mounting holes must be made in advance with an electric drill or punch. A fixing panel is fixed on the brackets, and on it is a block, and it is strictly horizontal.

This is followed by an intermediate stage of the communication installation. Air conditioning, as already noted, is due to the circulation of the refrigerant, which requires appropriate infrastructure. It is represented by a route that connects the indoor unit and the external capacitor. A channel for laying a drainage hose should also be provided. As already mentioned, it will be required to drain the condensate.

A cable, copper pipes for freon and an inter-unit communication line are laid along the communication route. First, electrical communications are connected, and then the pipeline. Immediately after the completion of the basic connecting operations, the ventilation and air conditioning systems should be tested by evacuation. With the help of compressor and pressure testing equipment, air is removed under pressure, after which the operation of communications is tested. As part of the first test, you should also check for leaks, generally assess the tightness and reliability of the fasteners. To check the density of the compounds, pressure gas is directed into the circuits. Then you can fill with freon.

Consumables for the air conditioner

During operation and during sudden repairs, consumables and materials may be required, which should always be in stock. The basic set of this fittings consists of hoses with pipes of a suitable format, fasteners, heat-insulating linings and protective panels. Particular attention is paid to the quality of anchor elements and brackets. They must have reliable seams and an anti-corrosion coating - only in this case the fasteners can withstand a load of several tens of kilograms.

Do not ignore the decorative component. If industrial units in this regard can not be of any value, then the household split-air conditioning system in the premises of a residential building is quite capable of emphasizing the stylistic nature of the interior. For decorative masking, special linings and grilles can be used. The same applies to the outdoor unit, which is decorated with aesthetic details corresponding to the facade finish.

Control system

Most modern climate control units receive remote controls in the kit. Directly on the indoor unit is also a panel with buttons (hardware or touch). In both cases, the user can adjust the temperature, air velocity, cooling rate and other parameters.

Particular attention should be paid to the implementation of the modes. As a rule, manufacturers lay in them a complex of microclimatic parameters oriented to certain working conditions. It is also worth noting the advantages of programmable air conditioning systems, which are provided by timers. The owner can not only configure the current operating parameters, but also set the equipment for the day and even weeks of operation in automatic mode.

Equipment Operation Tips

Climatic equipment requires a delicate management approach due to technological complexity. Therefore, to maximize the life of the device, you should focus on the following recommendations:

- Heat loss should be minimized by closing windows and doors. Direct exposure to sunlight in a room with a working air conditioner is necessarily excluded.

- Heaters and other heating equipment should also be turned off when the temperature drops.

- Intensive operation of ventilation and air conditioning systems should be balanced and appropriate instructions. So, in many models, work at extremely low or high temperature conditions is limited in time by protective automation.

- It is advisable to avoid sudden transitions between different temperature indicators with a large distance in the range.

Maintenance

Proper care of the air conditioner is the key to its long-term and efficient operation. During operation, a whole range of maintenance measures is carried out. First of all, attention is paid to the cleanliness of the equipment. You should start with the filters. Their most common form is mesh membranes. They are replaced once every 1-2 years, but in the active mode, manufacturers recommend flushing the filter every two weeks.

Comprehensive cleaning of the ventilation and air conditioning system is carried out using compressor equipment. Fine dust, stuck fluff and other dirt are removed by compressed air flows under pressure. The external surfaces of the indoor and outdoor units are wiped with a damp cloth or rags without the use of aggressive chemicals.

Of course, the probability of breakage cannot be ruled out. A malfunction can be indicated by a decrease in the intensity of cooling, a decrease in fan speed, leakage of freon, etc. With your own hands, you can eliminate only a part of the problems associated with violations in the closed loop connecting the functional organs - the evaporator, compressor, throttle and other components. Further maintenance of ventilation and air conditioning systems is carried out adjusted for previously identified malfunctions. At least once a season, the condition of consumables, the quality of the fasteners and the tightness of the structure should also be checked.

Conclusion

From the decision to organize the conditioning infrastructure in the room to the implementation of this idea, you need to go a long way. But first you need to make sure that this decision is really justified. After all, manufacturers are subtly aware of new requests and offer alternative equipment corresponding to them. So, today there is an increasingly active tendency to minimize sizes, optimize electricity costs and facilitate installation activities. Obviously, large-sized air conditioning systems hardly meet these requirements. , , , .

, . , . - , . . , . , , Electrolux, Daikin, Ballu, Mitsubishi NeoClima.