The place of joining of sheets of linoleum with each other, with other types of floor materials, as well as open edges, must be very well fixed. Otherwise, under the influence of moisture and mechanical stress, they can bully. In the end, such edges are overwritten, dirty and torn - the general appearance of a beautiful coating deteriorates. To prevent this, flooring manufacturers have developed special profiles - clamping or joining strips. With the help of these simple devices, the ideal type of coating is preserved for many years.

What functions does the clamping bar for linoleum perform

Getting the exact cut to fit the edges perfectly is not easy. Especially if the connection is not in a straight line, but repeats any bend. Therefore, linoleum soldering technology is not always suitable. If the thickness of the coatings is different, it is also difficult to achieve the accuracy of the seam. In all these and other cases, it is advisable to use a clamping profile, which provides:

- Seam protection. Even with very accurate joining of flooring sheets, there are always areas where there are slots that are invisible to the eye. In these gaps when cleaning the room, and just in the process of life, moisture and dust penetrate. After a couple of years of operation, a black stripe at the junction will certainly appear, and this is not the worst. The joint may diverge under the influence of temperature processes in the coating material itself, and over time the edges will begin to wrap. The clamping plate easily solves all these issues. The variety of color and texture options for finishing the pressure sills is huge.

- Leveling levels. For example, when laying tiles, no matter how thin the adhesive layer, the coating thickness of at least 5 mm is guaranteed. To fit linoleum exactly a millimeter into a millimeter is a painstaking task. You can, of course, use heat-insulating substrates, but they tend to break through, as, indeed, the budget floor material. Visually, this is not too noticeable, but when walking, it is real to catch on this invisible ledge. The bar comes to the rescue again. Its edges are cut off at an angle or zavolenov.

- Combining various types of coatings. The current trend is to design the floor covering with several types of material: insert circles, draw smooth lines, create fancy patterns, turns the floor into a real collection of paintings. Here the bar plays the role of a framework for these paintings. Made in one color, it combines all the diversity into a single form.

Pressure bar: features

Due to the great demand for a variety of finishing materials, several types of pressure strips for various purposes appeared on the market:

- The bar is straight. The simplest profile for fixing the joint of identical floor materials in height. It is rigid, curved at the end or with sides cut at an angle. Such a profile has mounting holes and is screwed to the base of the floor.

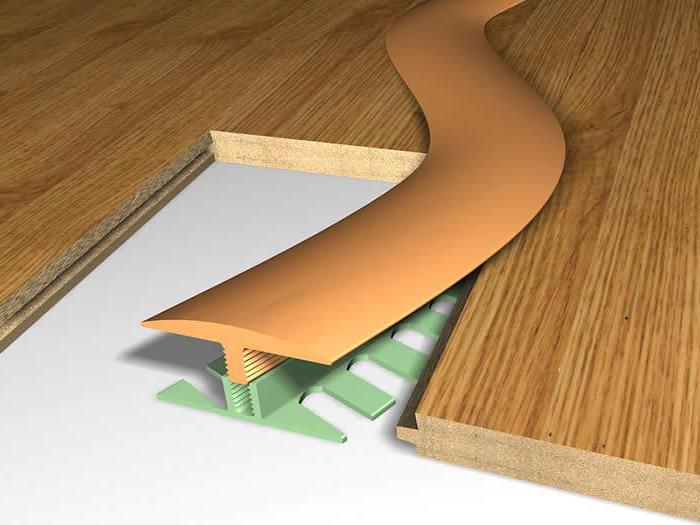

- Flexible clamping bar. Made of elastic plastic and has a guide protrusion from the bottom side, which should go into the butt gap. The profile is designed to design smooth wave-like compounds of the type: linoleum - tile; linoleum is a laminate. Fastening is carried out by means of glue.

- The profile is multilevel. Smoothes thickness differences of different stacked materials. Its main task is to make safe the operation of the coating, and also to prevent the destruction of the connection with constant gearing of objects.

- The terminal profile. It is used to fix the edge of the coating, which ends on the threshold or when entering the balcony, or in any other place where the continuation of the flooring is not supposed.

- Corner strip. Designed for flights of stairs. There are two types of these profiles. One serves to fix the floor covering, the other has a special ribbed surface to prevent slipping of the feet on the stairs. Sometimes such straps have a special rubber insert.

What do clamping profiles make

The most practical and widely used is the clamping plate "Technonikol" of metal, plastic and rubber.

- Metal. The material is an aluminum or brass strip. The profile is obtained by milling and drilling. After coating with paint and varnish materials, the planks acquire a different color scheme. There are monophonic and imitating the structure of wood of various species. They are not subject to corrosion and are resistant to wiping.

- Plastic. Cheaper material than metal. Plastic and ideal for closing curved joints. Such a clamping plate requires the use of reliable adhesives, since it is attached to them. It is also available in various colors, but it is less resistant to mechanical stress and can be easily scratched.

- Rubber. They are mainly used for covering rounded, oval, and similar joints, as well as an additional element of metal angular thresholds.

How to fix the joint with a bar

To fix the metal clamping plate, it is necessary to have an impact drill, hammer, curly screwdriver, marker, as well as screws and plastic dowels in the required quantity. The installation technology is as follows:

- The bar is laid on the joint so that a seam is visible through the mounting holes.

- Through the holes mark the points of drilling with a marker.

- Drill holes for plastic dowels to a depth of the length of the latter.

- Insert the dowels.

- They attach the bar and fasten with screws.

Conclusion

As you can see, a clamping bracket acceptable in price is a necessary thing, it solves many issues. The most important of these is ensuring the durability of truly expensive flooring. And if you turn on the imagination and change every three years such a peculiar decor element, for example, to a different color? It turns out almost a repair. And the mood improves, and money is saved!