Infrastructure for the distribution of energy networks over long distances, as a rule, provides for the organization of air networks. As delivery circuits, power lines (power lines) are selected , for the operation of which special supports are used. These are structures on which wires and associated fittings are fixed. Depending on the application conditions and network characteristics, power transmission towers of various types can be used. In the future, the quality of the organized network will depend on the installation and technical support of the line.

General information about power transmission towers

The support, which is part of the power line, performs the tasks of supporting the wires and optimal tension. Each support has in its design special fittings for fastening cable lines. In this case, the purpose of the route itself may also vary. This also applies to current transmission lines, and communication fiber optic networks, as well as telephone wires. The fact that the route belongs to one of the above categories partly determines the technology by which the transmission line supports will be installed in a particular area. So, the higher the voltage, the more responsible the installation. The quality of installation will be affected by auxiliary elements in the form of clamps and clamps. And this is not to mention the need to obtain a sufficient distance from the wires to the ground and the support body. Complex sections of the network require the development and preliminary calculation of the project for which installation operations will be carried out.

Varieties of supports for the intended purpose

Supports are intermediate, with anchor support, angular and special. The most common are intermediate structures installed on straight sections of lines. They perform the tasks of supporting cable routes and are not designed for additional stress loads. Anchor structures are also mounted on straight sections, but, in addition to supporting wires, they can also absorb the load from tension. For this reason, the power line anchor supports are durable and durable. As for the angular supports, they are used in complex areas with turns and transitions. Such structures are charged with their own lines, but the longitudinal load from the tension of adjacent networks can also be transferred. Complex configurations of bundles of trunk, transition and branch routes provide special supports. Often they are made for operation in the framework of specific projects for the organization of power lines.

Varieties of material

The most durable material for supporting structures is reinforced concrete. These are molded beams with a rectangular cross section, the structure of which is provided by metal rods. The advantages of reinforced concrete supports also include resistance to biological, chemical and climatic influences. Metal structures are also similar to reinforced concrete in some strength indicators, but they are used less often due to poor protection from rust processes. The most affordable solution is wood - such models cost 1-3 thousand rubles. average. For comparison: reinforced concrete power transmission towers on the market are available for 5-7 thousand. But wood is a short-lived element of infrastructure and requires updating already in the first years of operation. An alternative is a composite pillar. This material, like wood, is characterized by lightness and protection against corrosion, but at the same time it is not subjected to biological destruction processes. However, composite costs more than reinforced concrete.

Installation of power transmission towers up to 1 kV

Installation is carried out in several stages, but first, preparatory measures are carried out. If necessary, the installation points should be cleared and in some cases strengthened additionally. If installation is planned through forest areas, then deforestation is not necessary. The average distance between the power transmission line supports is 35–40 m, and it is necessary to choose the attachment points so that the trees and shrubs are 1-2 m from the column.

Next, drilling or digging a hole. If you plan to install reinforced concrete or metal supports, then you will need special equipment and a solution that forms the foundation for the integration of the support. Drill construction equipment will prepare a hole in which the pole will be installed. Manually digging holes with a depth of the order of 30-50 cm. This option is suitable for the wooden support of power lines or composite analogs. After fixing the column, traverses, insulators and brackets are mounted. The fixing of the wires themselves in simple schemes is done by wire knitting.

Features of installation of supports up to 10 kV

In this case, supports of large sizes are used, which have a large weight and a high level of operational responsibility. Therefore, installation technology has its own differences. In particular, to strengthen the lower part of the support in the soil, excavation pits are required . The very installation of power transmission line supports does not do without pouring the foundation into the prepared niche. Special attention is devoted to ensuring the reliability of the design. So, in order to protect against fires and other damaging processes, a kind of insulating trench is formed around the installation point. The radius is usually about 1-2 m. What is more important: the grounding of such supports is made of rod vertical elements made of angular steel.

Conclusion

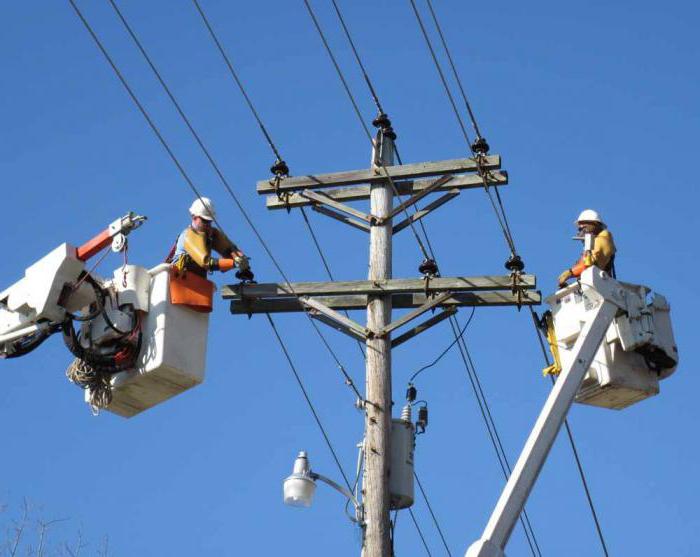

Overhead power lines in the overall structure can perform not only the tasks of energy distribution and delivery. Often, the route also acts as a communication channel for auxiliary needs. Another thing is that most of them also focus on technical support for local infrastructure. In this context, it is the transmission line supports that are of particular importance, since not only wires, but also additional functional fittings are attached to them. Also, the technology for organizing power lines involves the creation of maintenance points. These are critical areas where staff can take preventative measures - for example, assess line voltage levels, etc.