Nowadays, an automatic washing machine has become an integral element for every family, saving our time for more interesting activities than soaking, rinsing and squeezing dirty laundry. But with the external simplicity and comprehensibility of the work process, this hard-working assistant is a technically complex and very energy-intensive household appliance that guarantees high-quality and trouble-free operation only if the operating and installation rules are strictly observed.

Washing is serious

The electrical part of the unit is responsible for heating the water, rotating the drum and the electronic filling of the device, while working in aggressive conditions of high humidity and a chemically active environment. Therefore, the requirements for the wire for the washing machine - cross-section, the presence of grounding, the thickness and number of layers of insulation - are very high.

Despite the wide distribution, far from everyone, this connection is made in compliance with the necessary requirements, and this is already a matter of not just a breakdown of the device, but also the safety of people nearby.

The correct connection of the washing machine is a complex, quite expensive and not fast process.

Warranty obligations for almost any household appliance contain a clause that relieves the manufacturer of responsibility for the product’s performance during improper installation in preparation for operation. What is characteristic: some sellers, nevertheless, recommend that the installation be done by their "specialist", who in fact turns out to be both a driver and a loader, without the skills and permissions to carry out this type of work.

Selection of residual current device (RCD)

Before deciding which wire for the washing machine (see photo below) to connect, a number of issues have to be solved. And first of all, install an automatic batch switch (most often it is C16) and an RCD, placing it in front of the outlet of the connected device.

For groups of devices operating in conditions of high humidity with separate access, the setting for the RCD is set to 10 mA. With this value for the differential breaking current, automatic shutdown devices are produced for the operating current strength of not more than 16 A, which corresponds to the rating of the batch switch. With single-phase wiring, we select a two-pole electromechanical RCD type A (constant leakage type), with a short-circuit current of 6000 A.

Basic principles for safe operation of the washing machine

It is advisable to disconnect the batch switch after washing, completely disconnecting the socket, since if the ground is damaged, electrical appliances with a plug connected to the network can be shocked even when turned off. All disconnecting devices must be placed on a phase conductor. For greater safety, it makes sense to use bipolar batch switches, thereby protecting yourself from the theoretical possibility of transferring the phase to another wire, for example, as a result of an erroneous connection after replacing or checking the meter.

Grounding: what is good and what is bad

Never use the washing machine without an electrical ground. In houses of the old construction, wiring with a dullly grounded neutral is most often mounted, because the temptation is great to simplify the work, simply connect the neutral wire and the ground contact directly inside the outlet. However, this option is dangerous because in case of violation of the insulation of the neutral wire contact, the full voltage of the network will be supplied to the metal case of the device. It is equally dangerous to use a system of water and heating pipes as a ground loop. In the event of a failure of an RCD or a batch switch when a short circuit occurs on the machine body and pipes, 220 V will be supplied, which is deadly for everyone living in the house.

The most correct, if possible, is to extend a separate three-wire wire for a washing machine with a cross section of 2.5 mm 2 directly from the electrical panel. The task will be greatly simplified in a situation when an electric stove is installed in the apartment . Since the supply to the stove is carried out at a high power consumption (up to 7 kW) with high-quality grounding, this section of the wire for the washing machine will be more than enough. Now it remains to lay a three-core cable and connect it to the power connector of the plate.

Choosing a cable for connecting the washing machine

Let us consider in more detail the question of the need for a connecting cable. For proper electrical installation, it is required to calculate the wire cross section for the washing machine and measure the path from the connection point to the installation location of the outlet, taking into account all the bends. The rated current load for copper wire is 8 A per 1 mm 2 cross-section, and for aluminum wires - about 6 A. The power consumed by the device is indicated in the passport and directly on the product itself. For most household units of this type, it ranges from two to three kilowatts, which at a nominal voltage of 220 V corresponds to a load current of 10-14 A, respectively. Now you can answer the question, what section of the wire to use for the washing machine. With a certain margin, the best choice would be a copper wire with three conductors, a cross section of each thread 2.5 mm 2 in double insulation.

Problematic proximity of copper to aluminum

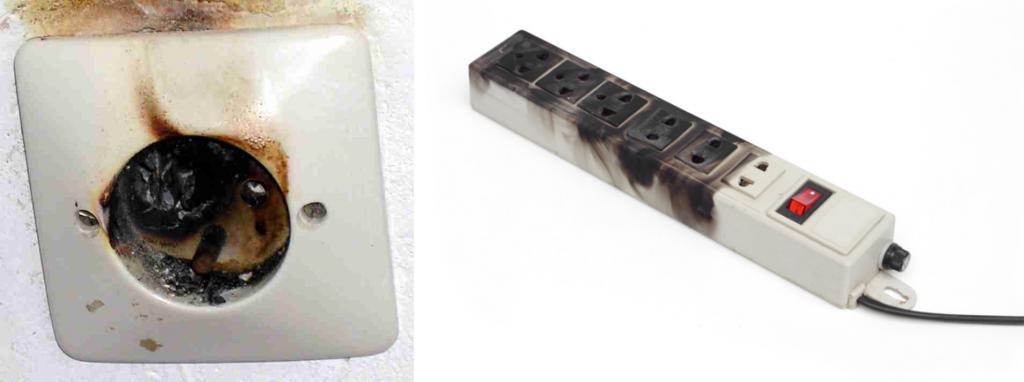

Most residential buildings of the old construction are characterized by the use of aluminum wire as the main wiring . Its connection with a copper cable is not directly allowed, because during the interaction these metals enter into a chemical reaction, as a result of which the contact point is oxidized, forming a dielectric film on the surface of the conductor. Such a connection quickly starts to heat up and regardless of the thickness of the wire section for the washing machine, especially at high load, it inevitably leads to the burning of the contact pair. This can lead to equipment failure and even a fire. To avoid this situation, specialized copper-plated clamps are required to interface copper and aluminum conductors.

It is also now possible to calculate what section of the wire is needed for the washing machine, when using an aluminum three-wire cable for supplying power. With a declared load of 2.2 kW, its cross section should be at least 3 mm 2 per thread.

Outlet selection

Now that we have decided what section the wire for the washing machine is necessary for us, we ask ourselves an equally important question - the connector used to connect the household appliance to the network. Most ordinary sockets are produced with a rated load of up to 6 A, while for modern washing machines with a power consumption of more than 2 kW, a socket of 10 A is needed, and at 3 kW it should already guarantee a current flow of up to 16 A. This is equal to degree applies to extension cords and adapters; connecting an energy-intensive device through them is strongly discouraged.

Since we plan to use the outlet in a room with high humidity, where there is also the likelihood of water being exposed to it, it is advisable to opt for a socket with a protective cover and rubber seals (it is marked IP44 and is classified as dustproof and moisture proof). Manufacturers offer sockets with a built-in RCD, which, if it is impossible to install it separately, can also serve as a good option when installing an access point to the mains for the washing machine.

Wiring

An ideal option for wiring is to place it inside the wall. Such installation involves a very laborious and dirty work. As an alternative, when installing the wires for the washing machine, the cross section of which we now know, you can use an electric box (cable channel) of the required depth. It comes in the form of a lockable white plastic gutter, usually two meters long. In addition to reliable fixation of the wire inside with a lid with a lock, this installation method has a rather aesthetic appearance and guarantees easy and quick installation of wiring. In this case, the socket must be protected from moisture on it and have a cover that closes the contacts when there is no connection.

Requirements for the safe operation of electrical wiring

According to the EMP, a bathroom is defined as a room with high humidity, which makes special demands on electrical wiring. This is associated with an increased risk for people in the room getting exposed to electricity.

In the bathroom you can not have electrical panels, switches, switching connections. Sockets must comply with a protection level of at least IP44 with a good ground, RCD or potential equalization device. The cross-section of the grounding wire must be no less than the wire having the largest cross-section in the room. It is not allowed to lay wires in an iron braid without insulation, as in metal sleeves and pipes.

It is necessary to use a three-wire wire for a washing machine with a cross section corresponding to the power consumption of the device, according to the above calculation. The priority is to use a solid copper cable, as it is more durable in comparison with aluminum and requiring a smaller cross-sectional area with equal load.

All actions associated with the electrical installation for connecting the washing machine must be carried out with power off.