Today, perhaps, there is not a single construction technology that would differ by only one advantage. Disadvantages and negative features are present in all methods. However, frame houses, reviews of tenants about which you can read below, are ideal in terms of price and quality, as well as operating costs and costs.

Positive reviews

The owners of frame houses note that such buildings have a negligible cost of construction. Today, this technology can be called one of the most affordable, this factor remains true even when taking into account the cost of decoration and foundation. The circumstances mentioned indicate that wireframe technology is common throughout the world. Frame houses, reviews of residents about which can be both negative and positive, according to consumers, are distinguished by a significant speed of construction. The duration of the home construction cycle is one of the lowest. Thus, a team of builders, which consists of three people, is able to erect a medium-sized frame construction in one month.

Construction Speed Reviews

If the customer involves the construction of the foundation and finishing work, then the duration can be increased up to 2 months. Frame houses, reviews of tenants about which you should have read before purchasing such a building, as the owners emphasize, differ in low operating costs. Besides the fact that the heating costs are low, the house does not imply the need for constant maintenance. Unlike a wooden building, which needs periodic updating of the external walls.

Reviews of thermal conductivity and sound insulation

Frame houses, the prices of which should be known to you before making a purchase, are popular today. Buyers quite often choose frame technology for their future home because of the low thermal conductivity of building envelopes. This circumstance can be called a big plus, as it allows you to reduce the cost of heating resources in the winter, as well as keep cool in hot weather. Thus, frame houses are distinguished by a comfortable indoor microclimate. Enclosing structures have a low heat capacity, which allows flexible use of the heating system. This is especially true for those rooms that need it. The owners have the opportunity to save money by increasing comfort. As for houses not intended for permanent residence, if necessary, the owners have the opportunity to flush the building in the shortest possible time.

Frame houses, residents' reviews about which you should be interested in before purchasing such a home, are distinguished by excellent soundproofing characteristics. This is due to the fact that during the construction process, sound insulation is laid inside the ceilings and partitions, which allows to achieve high noise absorption indicators.

Reviews about shrinkage and the choice of foundation

Choosing a house built using frame technology, as the owners of such housing emphasize, you will have the opportunity to lay communications inside the walls. This feature relates specifically to frame technology, which allows you to lay ventilation channels, electrics and heating / water pipes inside partitions or walls at no extra cost, as well as special purpose tools. This gives aesthetic advantages to the premises. Finnish frame houses are lightweight, so you can choose a lightweight variety of foundations for construction. The construction will be laid shallow, which allows to save by increasing the speed of construction. Modern consumers like the feature that houses do not sit down after the completion of the manipulations. This is a significant plus for the reason that you can begin to move in, as well as decorate immediately after the completion of construction. If a tree with the necessary humidity level was used, then the walls will not be skewed, and the house will retain its geometry after several years of operation.

Environmental and Earthquake Responses

Finnish frame houses are environmentally friendly, this is due to the fact that the main component of such a building is wood. In addition, environmentally friendly heaters of the type of basalt or mineral wool, oriented particle board and drywall are used. The materials used in the construction, acts as a product of the processing of natural components, which improves performance and does not pose a threat to human health. As buyers note, the frame house decoration can be done independently and with ease. There is no need to plaster the walls or create an additional frame inside. It will be enough to putty the joints, as well as the location of the screws. At the next stage, the owners can start gluing wallpapers, the walls do not need to be aligned, since they do not have errors. The same feature applies to the ceiling. The floor in the frame house does not need to be filled with screed, as is the case with the presence of slab ceilings. The surface of the rough foundation is already ready for finishing work. This reduces not only costs, but also time. Such buildings can be installed in earthquake-prone zones, they undergo a load of up to 9 points. An illustrative example is the fact that in Japan they prefer to use frame technology for housing construction. Frame houses for living are able to undergo a huge number of defrosting and freezing cycles. You can operate the house constantly or periodically, without maintaining the temperature at a certain level.

Possibility of year-round construction

To begin construction, according to experts and home masters, you can at any time of the year. However, the thermometer should not fall below -15 degrees. Winter frame houses can be built without the use of heavy equipment, you can do it exclusively with the help of a small team. This is due to the fact that in the process you do not have to use massive elements, which simplifies the work.

Reviews of the unique wall design

The frame house is assembled using a special technology, this allows easy access to internal communications, as well as thermal insulation. This may be required to replace the insulation with a new one, which will help extend the life of the building by several decades. The walls, according to the owners of frame houses, are devoid of gaps, which is a definite plus. Surfaces are characterized by perfect evenness, and existing leaks are filled with insulation. The presence of windproof membranes completely eliminates the flow of air masses inside the walls. If necessary, floors and walls can be dismantled, the process will be inexpensive and quick, you can assemble the building in a new place.

Comfort Reviews

Frame houses, prices for which can vary in the range of 1,200,000 rubles, are built without using wet cycles. This makes the construction completely independent of the availability of water supply sources, as well as the ambient temperature. Inside the premises, according to the owners, a comfortable microclimate is maintained throughout the entire period of operation. This is ensured by the use of drywall and wood. The walls have a small thickness, which saves square meters.

Negative feedback on the echo of the walls

Choosing frame houses, you can do construction yourself, but such buildings all have some disadvantages. Among others, the echoing of ceilings and wall structures can be especially highlighted. This disadvantage, as buyers emphasize, is characteristic of all floors and walls based on wood. This quality is due to the insignificant mass of the structure, which does not sufficiently dampen the vibration. The use of sound and heat insulation, as well as the use of heavy heat insulation materials based on mineral and basalt wool, partially solves this problem.

Negative feedback on the need to draft

Frame house designs are most often created by professionals. This is due to the presence of a minus inherent in a similar technology. It consists in the need to draw up a competent project, which involves the presence of nodes and mounting schemes. Technologically similar buildings are more complex compared to all others. The project must be prepared by specialists with appropriate qualifications.

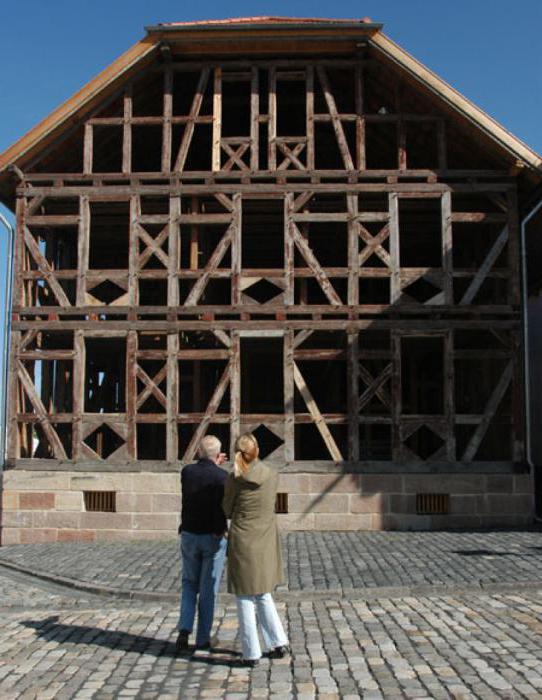

Construction of a frame house

Before starting work, you should consider the projects of frame houses. Some of them are presented in the article. The process of the device begins with the foundation, which is an extremely important stage. Most often, when using this construction technology, reinforced monolithic tape bases are used. You can choose the foundation of block, pile or column types. The craftsmen begin laying the bars, which will form the basis of the lower harness. It is laid on the foundation. Up to this point it is necessary to cover the surface with roofing material. The bars will have to be linked together by sampling in the corner parts. You can use one of the existing bundling methods, but in practice one of the options listed below is most often used. We are talking about sampling under a slope, which is called "in the paw," and the level log technique, it is called "in half a tree." In the corners of the joining of the bars , a reliable fixation with anchors or nails should be made.

To fasten the bars to the foundation, it is necessary to use nuts that are equipped with flat wide washers. The latter are necessary to increase the area of contact with wood. If you exclude the use of nuts, or fix the bars with narrow ones, installation can lead to the fact that the fasteners will be recessed into the bar, which will lead to poor-quality connection. During the installation of uprights, angular ones should be installed among the first. The cross section of the corner posts must be different from the rest. For the reason that the bottom bars are fixed in the corners with anchors, the corner posts are reinforced with metal corners, reinforced ones can be used as them. During the installation of the intermediate racks, you can use one of two methods for attaching corner elements. This includes the fixation of the struts of the strapping according to the cutting technology. Mounting racks can be made using galvanized metal corners. It is worth noting that the latter option involves faster and more reliable fastening, because in this case there is no need to reduce the thickness of the beam due to cutting.

Final work

Once the frame is strengthened, you can deal with ceiling beams. It is recommended to use perforated brackets or metal corners. The roof of the frame house should be arranged using exceptionally light materials in order to exclude unnecessary impact on the foundation of the building.