A wide assortment of various devices used for drilling holes is presented to the attention of the consumer . For work with wood, pen drills are intended.

These products are used by both joiners and professional furniture collectors, as well as home craftsmen. Information on the design features, technical specifications and sizes of feather drill bits for wood is contained in this article.

Acquaintance

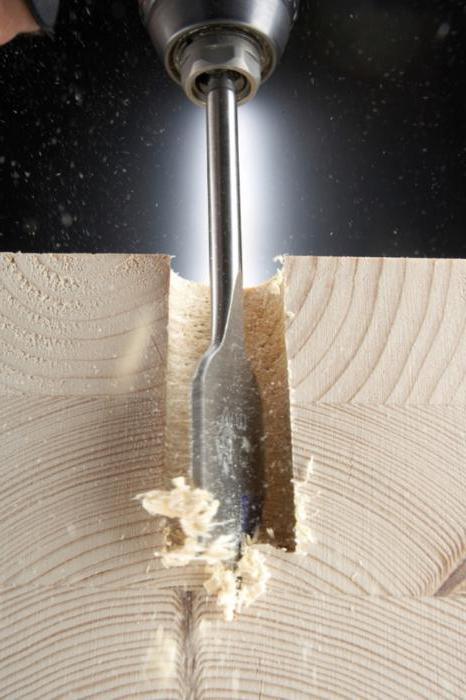

A pen drill is a special cutting tool designed for drilling various holes in wood. They can work both with natural wood, and with wood chipboards and MDF products.

The wizard can also use such an expensive tool as a disk cutter. However, judging by consumer reviews, such an application cannot be considered sufficiently justified. It is more expedient to get a pen drill on a tree. Compared with a disk mill, this tool is much cheaper, in addition, it is no less effective. They can be operated using either an electric drill or a conventional screwdriver.

Destination

Pen drills are used to create the following holes:

- Deaf. For them, there is no way out from the back of the product. With the help of blind holes, hinges are mounted when installing interior doors and small doors for furniture designs.

- Cross-cutting. They provide equipment with threaded connections: bolts and studs. Using through holes, the wizards install door handles and locks.

Tool device

The pen drill has a simple design. The tool consists of two parts:

- Working. It is a flat blade, equipped in the center with a special rigid protrusion. In the process of drilling, he performs alignment. The working part is also equipped with two cutting blades, which are located on both sides of the protrusion. The sharpened cutting edge extends from the tip of the protrusion to the edge of the working part of the drill. The tool has a right- or left-hand sharpening angle. These nozzles perform drilling in one direction. For such a cutter, a sharpening angle of 75-90 degrees is provided. There are also bilateral nozzles, the cutting angle of which is 120-135 degrees.

- Tail. The cross section has a hexagonal shape, due to which the drill bit is securely fixed in the drill and screwdriver chucks. In addition, the nozzle can be installed in magnetic adapters and extension cords.

Dimensions of the working part

In the manufacturing process of tools, the ratio of the thickness and width of their cutting parts is taken into account. For drills with a width of 5 to 10 mm, a thickness of 1-2 mm is considered acceptable. If the diameter of the pen drill is 1-2 cm, then the tool should have a thickness of 2-4 mm. When the width of the cutting part is more than 2 cm, its thickness should be 6-8 mm.

Sizes of pen drills

With this tool, you can easily make a hole with a diameter of 25 mm to 6 cm. Judging by customer reviews, the most popular are drill bits for wood 50 and 60 mm. If necessary, cut a hole with a diameter of more than 6 cm, the master will have to use other drills, since the pen drills are not adapted to cover large areas.

Color

In the manufacturing process of tool drills, finishing is envisaged. Its task is to give the product increased strength. In production, several processing options are used. Each of them gives the product certain operational characteristics. In the process, a coating is applied to the surface of the drill, the color of which allows you to judge the operational properties of the tool:

- Black nozzles have increased strength. In production, superheated steam is used for their finishing.

- Golden yellow drills have no metallic strain.

- Bright golden nozzles are treated with titanium nitride, thereby increasing the operational life of the products.

- The gray color is the tools that did not pass the finish.

When buying a set of wood drill bits, it is recommended that you take this aspect into account.

What should I look for when buying?

For those who wish to purchase a pen drill, experienced craftsmen are advised to pay attention to the following nuances:

- The tool must have a symmetrical configuration.

- Equipped with smooth cutting elements. The latter is a clear indicator that the cutting nozzle is a factory, not a makeshift model. Pen drills and their cutting parts have a high degree of sharpness and meet the standards only if they are made exclusively in the factory.

- During a surface inspection, the buyer must make sure that there are no defects in the form of chips or bumps on the surface of the drill.

Advantages

The advantages of feather cutting nozzles include:

- Low cost. The price of the instrument varies between 50-120 rubles. The cost will depend on the finishing technology used in the manufacture of the nozzle.

- A set of wood drill bits is equipped with cutting products, the diameters of which vary from 5 to 60 mm.

- Due to the design of the tool, it can be extended by 300 mm using a special nozzle for this purpose.

- The drill is easy to operate.

- In the case of wear of its cutting part, the master at home can always sharpen it. The exception is when pen drills are too worn.

disadvantages

Despite all the strengths of feather nozzles for woodwork, they are characterized by one and only minus. It consists in the fact that this tool has a limited cutting diameter, which does not exceed 6 cm. As a result, only pointed pointed cutters take part in the drilling process. In this case, the rounded sides of the drill come into contact with the edges of the groove on which wood fibers are formed. As a result, the surface of the holes are rough and not neat enough. Judging by the few reviews, these cutting nozzles on wood are very dull very quickly, and they often have to be sharpened repeatedly.

How to work with a nozzle?

After purchasing a set of pen drills, you need to choose the nozzle of the desired diameter from the package. It is recommended to work with this cutting tool following the step by step instructions:

- Before drilling a hole in a wooden surface, it must be marked out. The mark is applied at the point where the hole will be.

- Experienced craftsmen recommend working with these drills with a drill, for which a power regulator is provided. It is desirable that the power tool used be able to carry out 200-500 revolutions. If it is necessary to cut a hole of a larger diameter, the number of revolutions should be small. Judging by consumer reviews, a 50 mm wood drill bit will do its job much more efficiently at low speeds. As the diameter decreases, the revolutions increase accordingly.

- To make a deep hole, it is recommended to equip the drill chuck with a special adapter. In the event that it is necessary to drill a shallow depth, the master can immediately fix the cutting nozzle in the power tool.

- Bring the power tool with the nozzle to the place where the drilling will be carried out. In relation to the marking, the drill must be positioned perpendicularly.

- Start work, gradually increasing speed. It is recommended to periodically remove the drill from the hole. This requirement is due to the fact that as the depth goes into the wood, chips accumulate. By taking out the drill, the master thus creates an opening for the exit of wood waste.

- Work is considered complete if the cutting tool has gone deeper to the mark necessary for the master.

How to sharpen a tool?

Judging by the reviews of the owners, sharpening pen-cutting tools is not difficult.

For work, you need a diamond wheel mounted on a grinder. If such equipment is not available, a craftsman can use the quality rule. The sharpening procedure will be quick and easy if you follow the following sequence:

- Prepare a previously unused cutting tip. It will be used as a sample.

- During sharpening, it is necessary to periodically check the workable cutting nozzle with the geometric parameters of the worn-out new tool.

When guiding the cutting edges of a pen drill, it is recommended to be as careful as possible. The main thing is that after sharpening the central protrusion of the tool is not damaged.

According to numerous reviews by experienced craftsmen, it is not always advisable to sharpen such products. Very worn pen drills with highly sharpened cutting parts are considered to be waste material. Since such a tool is not very expensive, it is better to immediately buy a new drill than to waste time and “plant” a diamond wheel.

Finally

Thanks to the simple design of the pen drills, even an inexperienced person can use these nozzles. Nevertheless, in working with this drill, as with any other cutting tool, it is necessary to adhere to safety rules.