In order to choose the optimal insulation, you need to know how to calculate its thickness in each specific case, taking into account the materials used.

Compliance with the technology will significantly save on heating in the future and save it from high energy costs. Also, you will not have to spend money on a possible repair of the building due to the appearance of fungus, mold, structural damage or due to other negative consequences of improper insulation.

Thermal conductivity table

Material | Density kg / m 3 | The coefficient of thermal conductivity, W / (m * s) |

Mineral wool | 100 | 0.056 |

Mineral wool | fifty | 0,048 |

Mineral wool | 200 | 0,07 |

Marble | 2800 | 2.91 |

Sawdust | 230 | 0,070-0,093 (increases with increasing density and humidity) |

Tow dry | 150 | 0.05 |

Foam concrete | 1000 | 0.29 |

Foam concrete | 300 | 0.08 |

Styrofoam | thirty | 0,047 |

PVC foam | 125 | 0,052 |

Expanded polystyrene | 100 | 0,041 |

Expanded polystyrene | 150 | 0.05 |

Expanded polystyrene | 40 | 0,038 |

Expanded polystyrene extruded EPS | 33 | 0,031 |

Polyurethane foam | 32 | 0,023 |

Polyurethane foam | 40 | 0,029 |

Polyurethane foam | 60 | 0,035 |

Polyurethane foam | 80 | 0,041 |

Foam glass | 400 | 0.11 |

Foam glass | 200 | 0,07 |

The table shows that the leading position is occupied by the lowest density polyurethane foam. Even considering the high price in comparison with other heaters, this material is gaining more and more popularity. This is especially noticeable in private construction. In addition to its ability to retain heat, the material is not combustible and is not at all afraid of moisture.

Comparison of different types

- When choosing a suitable option, you should also know that the higher its density, the lower the thermal insulation properties. This is due to the fact that the air contained in the insulation is displaced by the material itself. For example, it looks like this: using a foam with a density of 30 kg / m 3 for floors, you will get them more durable, but not as warm as if you used a foam of lower density.

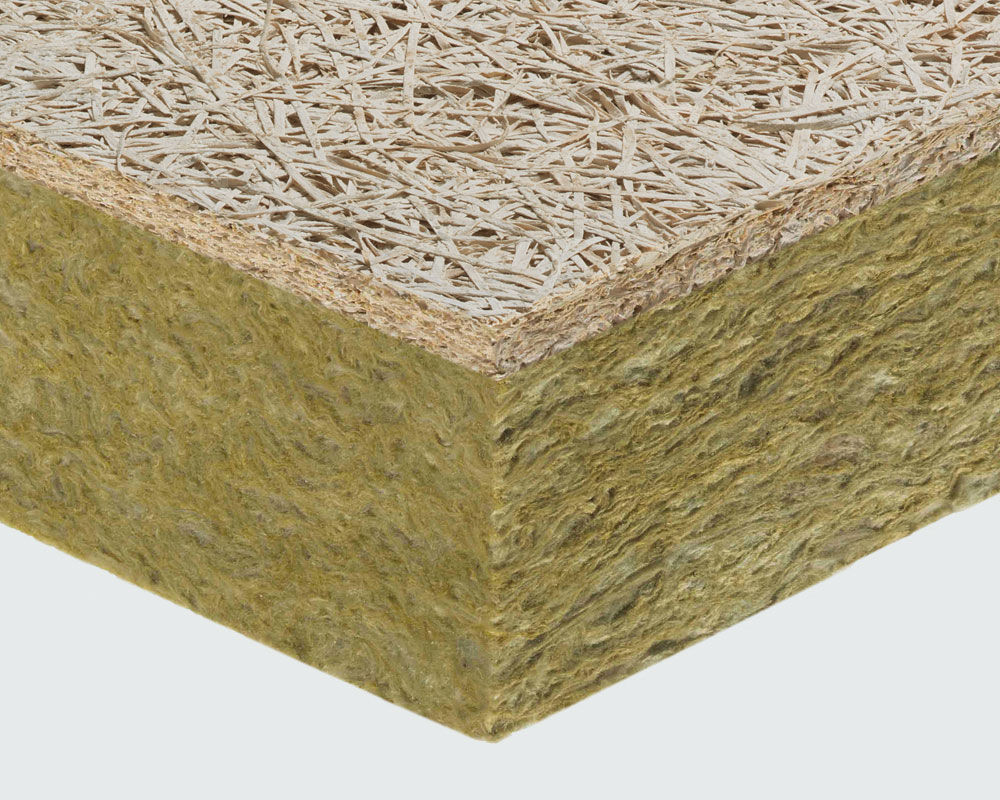

- Mineral wool and polystyrene have almost the same thermal conductivity. Choose a specific material, starting from the features of installation. Mineral wool with high humidity loses its heat-insulating properties. Therefore, if the operation of the insulation is expected with a risk of getting wet, then it is better to choose polystyrene, because even when a fifth of the cotton is wet, it will reduce its thermal insulation properties by half.

- Using sawdust increases the risk of spontaneous combustion. They also absorb moisture very well and lose their thermal insulation properties. Of the advantages of such a heater, it can be noted that it is an environmentally friendly material.

- Foam glass is a new generation version, quite light and inexpensive, but at the same time, it is very fragile and environmentally friendly material.

Formula for calculating insulation thickness

There are many resources on which you can calculate this indicator online. First you need to choose the best material. To do this:

- Familiarize yourself with the standards for heat resistance established in your area. Their values are written in SNiP.

- Choose from the table above the appropriate option.

- Conduct a heat engineering calculation of the thickness of the insulation according to the formula:

R = p / k, where

R is the thickness of the insulation layer;

P is the layer thickness in meters;

K - thermal conductivity coefficient of the insulation

If several different types are used, then the thermal resistance will be equal to the sum of the indicators of such materials.

Features of the use of several layers of insulation

- Make sure that there is no space between the layers and the air will not cool the insulation, and, accordingly, the structure itself.

- When calculating the indicator, add also the heat resistance of the structure itself, and especially the bearing walls, since this will reduce the final cost of construction. The final calculation of the thickness of the insulation will depend on the material and wall thickness.

- A material with lower thermal conductivity will have a higher thermal resistance.

Below, let's look at the features of the work of various structural elements.

Roof

Calculation of the thickness of the insulation for the roof is carried out according to the above formula, but it is necessary to take into account all the layers involved in the construction: wood or concrete for the ceiling, the material of the ceilings, the thickness of the plaster, etc. The most popular option, having an excellent price-to-thermal conductivity ratio, is mineral wool . It is perfect for indoor use, where it will be protected from precipitation.

When choosing basalt cotton wool for the roof, give preference to one that is designed to warm this particular part of the structure. This is especially important if you plan to equip the attic.

Do not choose polystyrene for the roof. It is prohibited by SNiP due to its flammability and harmful fumes to health.

When calculating the thickness of the floor insulation, take into account the fact that rolled materials over time give greater shrinkage and, accordingly, lose their properties. For the roof, it is recommended to use only plate types.

In addition to mineral wool, plates from extruded polystyrene foam will also be a good choice, since despite the absence of atmospheric precipitation, condensate can collect under the roof.

Floor

The calculation of the thickness of the insulation for the floor is no different from all the above calculations. You should consider all layers of materials involved in the construction of the building, as well as the presence or absence of a cold basement under it.

It is not recommended to use polystyrene, polystyrene, mineral wool as a heater inside the premises. The first two materials are due to their combustibility and harmful fumes, and the last because of their good ability to absorb moisture, which can subsequently lead to mold, mildew and rotting.

A cork insulation is a good option for the floor . By cons include its rather high price. However, it is also a very good sound insulator, so that two construction tasks can be solved at once. This material is strong enough, it is recommended to use it under a concrete screed and bulk floors. A beautiful texture allows you to leave the material as a finish coating, treating the top layer with a special varnish.

When choosing cork material for laying on the floor, as well as any other, it is important to correctly calculate the thickness of the insulation, since the principle of “more is better” does not apply here. You will not only significantly raise the level and reduce the useful area of the room, but also unjustifiably increase the cost of construction.

Ceiling

When calculating the thickness of the ceiling insulation, you should also determine what goals you want to achieve. For example, ceilings in multi-storey apartment buildings do not require insulation at all, if the construction was carried out without technological violations. In such houses, it is enough to lay a layer of sound insulation and thereby significantly reduce the material costs of repairs.

Private houses, on the contrary, often require insulation not only of the floor, but also of the ceiling. Let's look at situations when it is really necessary to carry out work.

- Under the roof is an unheated attic. If under the project there will be an unheated and uninhabited room under the roof, then at the construction stage it is necessary to lay insulation in the ceiling beams, sewing it up from below and above.

- The room is very cold in winter. Perhaps, the wrong calculation of the thickness of the insulation for the building was originally made. In this case, proceed based on the specific situation. First you need to sheathe the ceiling, if this was not done at the construction stage, and see how the general temperature in the room changes. If the situation does not improve, then, most likely, it will be necessary to review the entire thermal insulation system of the building.

- The attic is residential but not used in winter. In this case, the same principle applies as in non-residential premises. The temperature in the attic is much lower than in the living room and, accordingly, there is a large heat loss from the living room. As you know, warm air rises and penetrates through the ceiling into the attic. In addition, in contact with a cold surface, it turns into condensate, which leads to mold and rotting of wooden ceilings.

It is most advisable to lay insulation in the ceiling beams. You can use mineral wool and cork material for these purposes, because the moisture content in residential premises is low. Polyfoam is better not to use under the ceiling.