To heat technical rooms (garage, workshops, etc.), a working furnace is used for working off with or without supercharging. Proper manufacturing of the device allows you to purchase a good tool for space heating and water heating.

Waste oil is often nowhere to go, and as a fuel it is well suited, since you do not need to purchase and store firewood or consume electricity. Fuel consumption does not exceed 2 liters per hour. However, it does not need to be especially prepared in terms of heating, cleaning and pumping under pressure.

Advantages of the furnace at work

With proper operation and compliance with safety standards, the furnace has the following advantages.

- Effective heating of enclosed spaces: technical premises, greenhouses, domestic buildings.

- Quick warm-up of the premises.

- The device is independent of gas and electricity.

- The design allows you to cook food.

- In normal operation, the stove does not produce a lot of burning and soot.

- Simplicity of operation.

- Possibility of transportation due to small size and weight.

- No open flame.

- Scrap metal can be used to make the furnace.

- The furnace provides the burning of oil and its vapor. If used correctly, the device will not be flammable.

disadvantages

Unfortunately, he also has disadvantages:

- mining should be filtered, since impurities clog the supply tube;

- the need to build a chimney longer than 4 m;

- the presence of open hot surfaces;

- the need for frequent cleaning of the stove and chimney;

- foul odor of fuel;

- contamination of the premises and clothing in contact with mining;

- The furnace can be extinguished only after complete burnout of the fuel;

- fire hazard in case of improper operation, for example, when overflowing by exhausting the combustion chamber;

- oil lights up only when heated to flash point;

- buzz in the process of work.

Operating principle

The basis for the kiln for mining was kerogas, which was previously used in cottages and in villages. Kerosene was used as fuel in it, the vapors of which were burned in a separate chamber. In order not to waste money on fuel, a method was developed for burning used oil, which some enterprises give cheaply or for nothing.

Making a stove with your own hands is not so difficult, but the processes of oil combustion occurring in it are complex. In order for the vapors to completely burn out, they must be twisted for better mixing. For complete oil combustion, heavy components must first be split into light ones. The process is called pyrolysis. For evaporation, heating the oil itself is necessary.

The principle of operation of the oil furnace is that at first mining is ignited in the lower chamber. In this case, air enters through the throttle valve, which regulate the intensity of combustion. Oil vapor with air rises up a vertical pipe, which, together with the upper tank, is a afterburner. The mixture is mixed under the influence of the Coriolis force. The intensity depends on the correct choice of the length and diameter of the combustion chamber.

For complete combustion, insufficient air flows through the lower damper. Therefore, it is additionally sucked through holes made in a vertical perforated pipe connecting the tanks.

Then the gas flow passes into the final afterburner, made in the form of an expanded tank from above. It is made with a horizontal spacing between the exit of the combustion chamber and the inlet of the chimney, necessary to create a temperature jump between the zones of oxygen and nitrogen oxide afterburning. The fact is that at temperatures below 600 0 C nitrogen oxides are more active than oxygen, and they oxidize fuel particles in the first place, decomposing at the same time. With increasing temperature, oxygen becomes the main oxidizing agent and harmful substances escape through the chimney into the atmosphere. Therefore, high temperature in the upper tank is undesirable.

Types of waste oil furnaces

The furnaces operate on the principle of afterburning fumes when the oil is heated. A pyrolysis unit is suitable for this fuel, where it can be heated in a vacuum chamber. Vapors form in it and enter the afterburning furnace. There, air is supplied to maintain combustion. Vapors burn with intense heat.

The furnace can be done independently. The material may be gas cylinders, pipes or sheet steel.

How to make a small- capacity oven yourself

If you own the technique of electric welding, an oil furnace can be made independently. Materials are prepared according to the drawings of the furnace.

To assemble the device, some tools are required. It:

- apparatus for welding;

- grinding power tools;

- drill with drills;

- locksmith tools.

After assembly, the joints are checked for leaks so that oil cannot leak through welds and seals.

The oil furnace at the end includes two cylindrical tanks connected by a perforated pipe. The upper tank contains a partition inside and is offset relative to the lower axis. Round containers can be replaced with square or rectangular. The stove will not work worse. The structure is mounted on the floor with welded legs.

A conventional oil furnace has a capacity of no more than 3-4 kW. It can be done more by proportionally increasing the size. The next step is the installation of two afterburners, a mining tank with feeding into the first combustion chamber and a sliding firebox. The most efficient is a supercharged oil furnace. Obtaining power of more than 15 kW by increasing the size is impractical. The evaporation rate of the oil has a limit above which soot and children appear.

Supercharged mining furnace

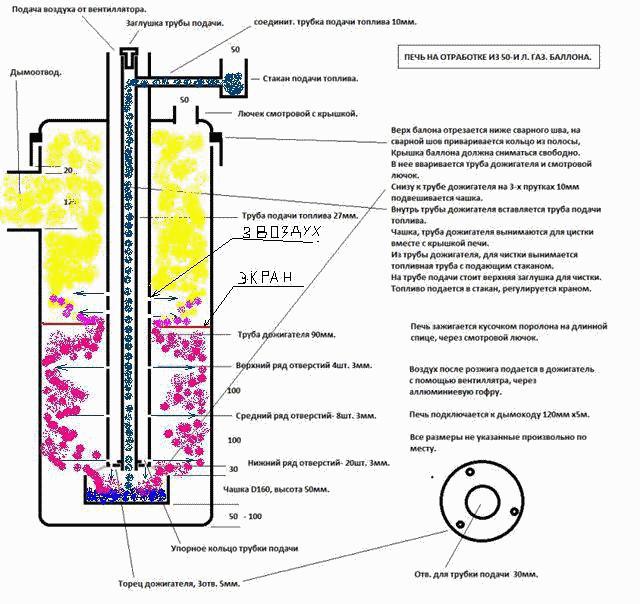

The manufacture of two chambers requires high-quality welding, so the design is complex. It’s easier to do everything in one tank. All physical and chemical processes will occur in it. In this method, the selection of heat from the combustion products does not interfere with the operation of the combustion process. The best option is to work out a gas cylinder using boost.

The stove is a closed vessel with a shutter on top to regulate the air supply. Through the central part, air is supplied from the fan through the pipe. After it, it is necessary to install a check valve so that flue gases do not enter the room after the forced air supply stops. In the lower part of the discharge pipe, many holes are made for supplying the necessary amount of air to the afterburner.

Homemade furnace designs

An exhaust gas furnace with a supercharged gas cylinder has increased thermal power. With improper air supply under pressure, the opposite can be achieved until the combustion process ceases. It is convenient here to increase the length of the chimney by making a horizontal section, turning at the end into a vertical one. At the same time, the heating of the room is improved due to the larger heat transfer surface, but you should be aware that if the length of the horizontal sections is too large and there are turns of the chimney, the stove will not work without pressurization. The height of the pipe must be at least 4 m, diameter - at least 10 cm. No more than two turns of the chimney by 90 0 are permissible.

The supercharged and refueling furnace can work for a long period. It is impossible to increase the size of the combustion chamber: the oil will not warm up. If at the same time it turns out to melt it, uncontrolled burning of a large amount of fuel creates a fire hazard. The tank is filled not more than 2/3 of the volume in an amount of up to 0.5 liters. Refueling can be provided through a tube with a tap according to the law of communicating vessels, or fed from above by a drop method through a funnel through a pipe. Small portions of oil falling on a hot bowl instantly evaporate and ignite. The advantage of the method is the absence of a large amount of boiling oil in the combustion chamber, creating a danger of release. Then even a supercharged mini-furnace can heat the room for a long time. The difficulty lies in ensuring the continuity of the drip feed process, which is usually controlled visually. This requires thorough cleaning and dosage. Industrial models should be preferred here. A supercharged and refueling furnace works better when oil is sprayed with air.

Such a device is built into a potbelly stove, and it works efficiently. It is important to provide visual control of the oil supply from outside the furnace. The flow rate is regulated by a tap so that a thin stream arrives. This changes the power. A large amount of fuel does not need to be supplied. Here the effect is ensured by dropping oil on the hot surface of the cup. When there is little fuel, the furnace can be easily extinguished by shutting off its supply.

Home-made structures are conveniently powered from an external tank through a float fuel level controller. The flow of fuel into the combustion chamber is created through interconnected vessels. The power of the furnace changes due to the air damper.

Supercharging can be used to increase traction, since the effective removal of combustion products is no less important than the injection of oxygen into the furnace. The hood is improved in two ways - injection and ejector.

The ejector design of the supercharged stove is preferable, since there is enough fan with a capacity of 1500 l / h (kitchen, computer or industrial VN-2).

Means for increasing furnace efficiency

A simple supercharged mini-furnace does not always suit users due to low productivity and low functionality. To improve its performance, additional devices are used.

- Development furnace with a water circuit. The operation of the furnace with the selection of heat for water heating is organized by tying the casing with a coil or creating a water jacket in the chimney. In the first version, the coil is made of a copper pipe, built into the heating system of the house. Through it, the coolant is circulated. A metal water jacket is made at the top of the furnace body. Through it, the liquid coolant is also circulated. The simplest devices are a pipe passing inside the afterburner and a casing in the chimney. For the supercharged working furnace to be effective, the amount of water in the tank in contact with it must be at least 30 liters. The economizer allows you to heat rooms with large areas. The furnace with a water circuit must have an expansion tank with emergency drain if the liquid boils. It is not recommended to install a membrane tank.

- Air heat exchanger. Many confuse it with supercharging, but the principle of operation is different for them. The simplest heat exchanger is blowing the stove with a fan. The method does not require any structural changes, and the heating of the room is improved. You can also drive air through a pipe mounted in the afterburner or through a duct mounted on top of the stove. The main difference between the air heat exchanger and boost is that the air does not come into contact with fuel and combustion products, but is heated through the wall. It is not recommended to cool the afterburner too much, since environmentally harmful nitrogen oxides are burned in it. It is better to take heat from the chimney, at the entrance to which the temperature of the combustion products is about 400 0 C.

Furnace operation

First, the furnace is ignited. Rags, paper and flammable liquids are used here. Solvent or gasoline is poured onto the surface of the oil and quickly ignited with a long torch. You can not wait long, otherwise a mixture of flammable liquid vapors with air forms and ignition occurs with cotton. Ignition with flammable liquids requires special care.

Fuel overflow is not allowed, otherwise an outflow may occur. After warming up, the oil begins to boil. The process is regulated by an air damper.

Tanks are periodically cleaned with a wire brush. Places of accumulation of soot are tapped with a hammer.

The operation of such a unit as a working out furnace with a water circuit is constantly monitored, since it is necessary to ensure that the amount of coolant is not below the norm. Antifreeze should be handled carefully, avoiding contact with the body.

Conclusion

Burning used oil is preferable to refining. Moreover, a special supercharged working out furnace has been developed, which does not require heating oil, but it is possible to burn oil directly. The feasibility of its use also lies in high efficiency, reaching 80%. A self-made supercharged kiln can be made from improvised means, which will save significant money.