Even those who are far from agriculture know that vegetables ripen in greenhouses much earlier than in open ground. Previously, plastic film or glass was used for their construction. Now science has created polycarbonate for greenhouses and other structures, which was immediately appreciated. If you still hesitate with the choice, let's take a closer look at what the new material is good and how to work with it.

Polycarbonate

This material is a thermoplastic made from polyester and phenol. It is made monolithic, that is, solid, and cellular, made in the form of cells filled with air. Polycarbonate for greenhouses is used only cellular, since it is the air contained in the cells that retains heat. By color, it is transparent, blue, turquoise, green, golden. Each has its own scope, but it is more reasonable to cover greenhouses transparent. In addition, polycarbonate is available in the form of sheets of various thicknesses (4, 6, 8, 10, 12, 16, 25, 32 mm). Of course, the thicker the material, the stronger it is, but for small structures, sheets with a thickness of 4 or 6 mm are successfully used. Of great importance is the brand of the manufacturer. Chinese polycarbonate is cheaper, but in quality it is significantly inferior to European counterparts, which are produced with a minimal addition of recyclables and a mandatory anti-UV protective layer, which increases the service life of the greenhouse. All this determines the cost.

Advantages

Recently, using polycarbonate in a greenhouse has become not so much fashionable as profitable, because this material has a lot of advantages over traditional glass and film. The main advantages are as follows:

- polycarbonate saves heat better (achieved by cells with air);

- transmits light rays well and delays ultraviolet (if there is a special coating);

- able to scatter light, which improves plant growth;

- Compared with glass, it is lightweight without loss of strength;

- plastic (can bend, which is used to create arches);

- withstands temperatures from -40 to +120 degrees Celsius, that is, it is quite suitable for most regions of Russia;

- unusually strong, does not break when struck, does not break, does not leave fragments;

- it is convenient in installation (it is easy to cut, drill), it is quite simple to mount polycarbonate, special equipment is not required for this.

disadvantages

Before you make a greenhouse made of polycarbonate, it will be useful to get acquainted with its shortcomings. Unfortunately, while scientists have not come up with material that is one hundred percent perfect. In this case, the following should be taken into account:

- polycarbonate is not devoid of temperature deformations (in other words, it expands in the heat, contracts in the cold, and the gaps can reach 3 mm);

- combustible (during combustion it melts, but the fire does not spread);

- abrasion resistance is not particularly high (easy to scratch);

- may be damaged by large hail.

Where to begin

So, the right choice of material is made. Let's figure out how to install a polycarbonate greenhouse. You need to start by choosing a place. Since light is one of the main stimulators of plant growth and development, it is advisable to arrange your design with the long side from east to west. However, in regions where strong winds are regularly observed, it is necessary to take into account the wind rose so that the vector of maximum air movements (squalls) is not perpendicular to the widest side of the greenhouse. According to the creators of polycarbonate, this material has increased wind resistance, but no one guarantees the strength of the frame. Therefore, it is better not to take risks.

Material calculation

The second stage of preparation is the calculation of the required number of sheets. They are available in a standard width of 2.1 m, and the length is 6 or 12 m. They can not be installed horizontally, only vertically, that is, you need to place a side 2.1 meters long in the base. The number of sheets will depend on the desired length of the entire structure. There are two types of greenhouses under polycarbonate - arched and "house" type. In the latter version, the roof is made both symmetrical and asymmetric. It does not affect strength and productivity, who likes what more. The width of this design depends on the type of project. For an arched structure, it is usually 3.8 meters. This is for 6-meter sheets based on their bending curvature (optimal radius 1.9 m). As a result, for an arched greenhouse of 12.6 x 3.8, 12 sheets of 6-meter length for a wide part and 2 more sheets for side walls will be needed.

Choose the type of frame

Before installing a polycarbonate greenhouse, you need to decide on the frame. 3 types are used: wooden, from metal pipes and profiles. Wooden frame is the cheapest and most convenient to use. Prefabricated collapsible greenhouses are most often presented in the form of pipe parts, which are connected into a single structure during the assembly process. It should be noted that it is not recommended to drill holes in them, since this reduces the strength of the bearing part. With any choice, the frame material must have a corrosion-resistant coating, because the humidity in the greenhouse is always quite high. As for wood, it is impregnated with copper sulfate and antiseptic. Pipes must be at least 20 mm in diameter, with a wall thickness of 1.5 mm or more. Remember, light metal structures are deformed from snow loads and cannot withstand strong winds.

Foundation

Any capital structure is installed on the foundation, including stationary greenhouses. There are several types of foundations that differ in price, reliability and labor. The most common:

- From wooden bars. This is a very simple, cheap and mobile (you can move to a new place) design, but it is the most short-lived, even with thorough anti-corrosion treatment.

- Brick. They dig a trench for it, fill it with concrete, and after hardening (after 7-10 days) a brick is removed. During masonry, bolts are inserted in advance, which are then used when installing the frame.

- Blocky. It differs from the previous one in that after filling the trench with concrete, special blocks are recessed in it.

But more often, small structures are made without a foundation using asbestos-cement pipes. Before installing a polycarbonate greenhouse with or without foundation, the corners of the future structure are marked on the ground with pegs and a cord. Then they either dig a trench of about 100 x 200 mm (for the foundation) or dig holes with a depth of 1 meter. Pipes are inserted into them so that their ends stick out of the ground. For stability, sand is poured into the cracks between them and the ground, which is densely compacted.

How to install a polycarbonate greenhouse. Subtleties of installation

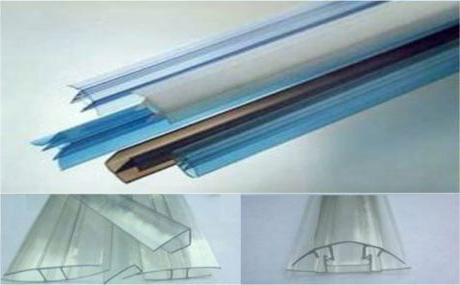

If the frame is made of wood, the bars are sharpened from one end so that they fit snugly into the pipes protruding from the ground. For strength, a frame of bars or boards is attached to the supporting (angular and intermediate) posts on the bottom and top. Growing any vegetables in a polycarbonate greenhouse and getting good yields is possible if you have one, preferably two doors and several window leaves, or you can install ventilation. If the greenhouse is without a foundation, galvanized iron tapes with a width of 250 mm or more are attached around the perimeter (bottom). They must overlap one another to a width of at least 50 mm. If a brick or block foundation is used, a waterproofing layer is necessarily provided. Now you can proceed with the installation of polycarbonate. It is very good if rubber or rubber gaskets are attached to the frame. Holes are drilled in the sheets and attached to the frame using self-tapping screws (a variant of wooden rafters) or screws that are screwed to the iron gaskets. Then the load is distributed more evenly. Joints and corners are sealed with special polycarbonate profiles. Doors and windows are performed in the classical way using hinges. If desired, you can install heating and additional lighting.

Exploitation

Caring for a polycarbonate greenhouse is simple. The main thing is that with nothing, even a dishwashing sponge, do not damage the protective layer of the material and scratch it with nothing. To this end, wash the greenhouse both outside and inside with only water and a rag or the soft side of a dishwashing sponge. Sometimes it is allowed to use a soap solution, but not chemical detergents. This disinfection is carried out before each landing. Greens, tomatoes, radishes, cucumbers grow well in a polycarbonate greenhouse, as well as any seedlings. But we must not forget about the careful cultivation of the soil from various types of pests, and especially mushrooms and all kinds of rot, for which a humid microclimate is very favorable. On this spring care has been exhausted. In the summer of the greenhouse it is advisable not only to ventilate, but also to shade. To do this, use awnings or spray a solution of chalk on the walls. It is also important to ensure that the soil does not dry out. In the fall, in addition to the main cleaning, props are installed in the greenhouses so that the structure withstands the snow load. Some summer residents generally disassemble polycarbonate. In winter you need to regularly sweep away snow with a soft broom.

Planting plants

Having established the long-awaited greenhouse, everyone dreams of early and necessarily high yields of tomatoes, peppers, cucumbers, radishes and other crops. To make it that way, planting in polycarbonate greenhouses should be in compliance with the rules of plant compatibility and taking into account the peculiarities of caring for them. So, tomatoes love potash soils and relatively low humidity, and therefore frequent airing. Bakhchev, which can also be grown in a greenhouse, drafts are contraindicated. Pepper grows well in the shade, that is, it can be planted densely, about 6-7 bushes per 1 sq. M. Salads need organic matter and moisture, and cucumbers respond well to both organic and mineral nutrition. Some gardeners before planting greenhouse seedlings, so that the land does not empty, sow early varieties of radish, herbs, lettuce, and Beijing cabbage. But all this should be removed at the time of planting the main culture. In general, growing several types of vegetables in one greenhouse is quite difficult. Experienced gardeners recommend that beginners learn on any one and only with the acquisition of experience switch to mixed planting.

Growing cucumbers

Cucumber is a tasty, healthy, but extremely moody vegetable. In open ground, he has a bad tendency to "burn" under direct sunlight. The same thing happens after insufficiently ecologically clean rains, from which not a single gardener is safe. Cucumbers in a polycarbonate greenhouse are protected from all this, therefore they bear fruit there for as long as possible. The main difficulty in growing is maintaining the right temperature and humidity. Cucumbers do not like airing, so there is no need to do this often if the room temperature does not exceed +25 degrees Celsius. The soil for cucumbers needs to be loosened regularly so that the roots can breathe. Top dressing is carried out with organic and mineral fertilizers, but no more than 4-5 times per season, and the first should coincide with the beginning of flowering. The scourge of all greenhouses is pests. For cucumbers, this is aphid, powdery mildew, false, greenhouse whitefly. Against them, it is recommended to conduct treatment on time with special preparations, infusion of bitter pepper or walnut leaves. And the last - grown plants must be tied up, so that the crop is higher, and the fruits are picked in time.