The range of steel corners is divided into two types of rolled products: equal and unequal. Based on the name, it can be understood that the first parts have the same wall width, and the second, respectively, of different widths. Unlike the assortment of beams and channels, the combination of varieties and types of these corners is much wider.

Consider what this term means. The range of metal corners is a list of geometric data, shelf dimensions, remote weight, and tolerances. Also included are delivery conditions. Below we will consider all these characteristics.

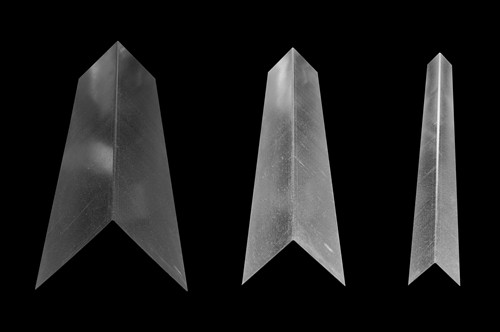

Assortment of unequal corners

It should be noted that all corners should be made exclusively according to the requirements of GOST. This type of material is produced in accordance with GOST 8510-86 from low-alloyed (these are grades 08G2S, 16GS, 17GS, 17G1S and many others) and carbon steel (grades st0, st4ps, st4sp and others).

Despite the fact that the creation of metal products, as well as their structural forms, is quite extensive and diverse, the manufacture of these structures is quite economical. This is facilitated by the assortment of unequal corners, in which a wide variety of different hot-rolled profiles. As well as frequent gradation of product sizes.

Properties and characteristics

Perhaps the main and most important characteristic of these metal parts is strength. Its indications may change during the freewheeling. This is the name of the metal hardening procedure, which occurs due to plastic deformation. When editing steel, where the thickness of the shelf is 3-5 mm, as well as other power work, some properties must be taken into account. For example, if you increase the force of pressing the punch instead of improving the quality of the fitting density during testing on the plate, then due to warping of the metal, the result will be absolutely opposite. If you produce a corner, a GOST assortment that does not meet, metal cracking is often observed in areas where the fretting procedure was carried out. Thus, these designs do not have the required margin of safety, because their service life is significantly reduced.

What you need to know when purchasing?

When choosing a corner, you should definitely know where it will be located and what kind of environment it is. If the latter is aggressive or has high humidity, the best option for buying is a product made of galvanized steel. Only in this case it must be performed in accordance with all the rules and requirements of GOST. The range of corners from this type of steel is most often used in galvanized power transmission towers.

Production and use of unequal galvanized steel profiles

L-shaped profiles are made in two ways - hot and cold galvanizing. Hot dip galvanizing makes the products more durable. Therefore, hot-rolled steel unequal corners, the assortment of which is quite wide, are used in structures with a heavy metal load. For other cases, profiles of cold galvanization are perfect.

The mass of the unequal angle according to GOST 8510-86

Corners have a very wide selection of sizes (from 25 mm to 200 mm), respectively, and their mass will also be different. In the table, we consider some profiles.

Corner marking, | AxB shelf dimensions | Wall thickness | Weight one meter | Meters per ton |

25x16x3mm | 25x16mm | 3mm | 0.91kg | 1098.9 |

40x25x4 | 40x25 | 4 | 1.94 | 515.46 |

65x50x7 | 65x50 | 7 | 5.98 | 167.22 |

According to GOST - an unequal angle, the assortment of which is quite wide, should be made of carbon and low alloy steel grades.

Quality, production and efficiency of hot rolled corners

The production of these profiles is performed according to GOST, which requires certain sizes and accuracy. But in the production of custom-made corners can be 7, 9, 12 meters long. And finished products can be made with increased accuracy.

GOST 8510-93 - unequal shelter, the range of which meets all standards. In order not to be deceived and not to buy a marriage, be sure to purchase products according to the State standard.

The same-shelf corner must comply with standard No. 8509-93.

These materials are used quite widely. They are in demand in construction, the creation of a variety of metal products. They also create metal structures, even in everyday life it is quite difficult to do without this profile. For the manufacture of hot-rolled corners, grade 3 steel is used. But in the construction, the strength of this model is not enough. Therefore, profiles are produced mainly from the brand 09G2S. Corners from it can be installed without weighting. For the manufacture of profiles, the most popular metal is ordinary-quality black steel.

Profile No. | Larger Shelf Width | Width of smaller shelf | Thickness | Shelf Radius | Radius | Sectional Area (cm²) |

5 / 3.2 | 50 mm | 32 mm | 3 4 mm | 5.5 5 mm | 1.8 mm | 2.42 3.17 |

8/5 | 80 | fifty | 5 6 | - | - | 6.36 7.55 |

11/7 | 110 | 70 | 6.5 8 | - | - | 11.45 13.93 |

Hot-dip galvanized steel corner - assortment

Due to the good corrosion resistance of the metal, the main purpose of such a corner is to fix the external structure. Galvanized steel is used in two types of construction: civil and industrial. For example, when covering a building with a roof, galvanized roof parts are used. Such corners look more aesthetically pleasing and modern. Therefore, they can be used when decorating buildings, even from the inside.

Equilateral type

It is quite durable and at the same time relatively light. Due to such advantages, this profile is often used in the construction and installation of load-bearing and non-bearing metal structures and bases. The corner can not only replace the reinforcement, it will make the structure much stronger. And its installation is much simpler and takes less time. Despite such a number of advantages over fittings, isometric corners can be purchased at almost the same price.

The equal-sided corner has the correct L-shaped section shape, is made on pipe mills from high-quality structural metal. Such profiles are one of the main and basic elements of metal structures.

Fields of application

Steel corner, the assortment of which corresponds to the State standard, is used in many areas of construction. The main ones are:

- Monolithic concreting.

- Construction of rigid reinforcing structures.

- Installation and device jumpers, as well as other cases.

- In combination with other profiles, like channels, a corner is used to reinforce concrete as a rigid reinforcement.

- Heavy and heavy spans and ceilings.

Also, metal corners are often used in order to connect handrails of different types.

They also use these profiles in the connection of various elements of the fence. Today it is very difficult to meet an established solid fence that would not have bends. Therefore, to connect the bends, the existing range of corners is also often used. Their steel will help the fence withstand strong winds and other natural disasters. Another application of the L-shaped profile in everyday life is to help create a home interior.

Most furniture factories also use metal corners in their work, even if it is upholstered furniture. After all, its connections without the use of these parts will not be able to withstand a large load. This, in turn, sooner or later, will lead to its breakdown.

Varieties

The assortment of the isosceles corner is very extensive and has more than 20 profiles. Consider several types.

- Profile No. 2: 1) shelf width - 20 mm; 2) thickness - 3.4 mm; 3) the radius of the internal rounding is 3.5 mm; 4) the radius of curvature of the shelf is 1.2 mm; 5) sectional area - 1.13, 1.46 cm²; 6) mass - 0.89, 1.15 kg.

- Profile No. 11: 1) shelf width - 110 mm; 2) thickness - 7.8 mm; 3) the radius of the internal rounding is 12 mm; 4) the radius of curvature of the shelf is 4 mm; 5) sectional area - 15.15, 17.2 cm²; 6) mass - 11.89; 13.5 kg

- Profile No. 14: 1) shelf width - 140 mm; 2) thickness - 9, 10, 12 mm; 3) the radius of the internal rounding is 14 mm; 4) the radius of curvature of the shelf is 4.6 mm; 5) the cross-sectional area is 24.72, 27.33; 32.49 cm²; 6) mass - 19.41, 21.45, 25.5 kg.

Despite the variety, the assortment of an isosceles corner must comply with all the standards and rules of GOST. If marriage is noticed, you should refuse to acquire a profile.

Production and Specifications

Metal corners are made according to GOST 380-94 standards - for carbon steel, or GOST 19281-89 - for low alloy steel, which is characterized by high strength. Metal processing in these cases is hot rolling.

A wide range of product applications is explained by their technical characteristics:

- Products have a very high level of rigidity.

- Despite the rigidity, the corner has a fairly small weight. Take, for example, a meter section of a part that has sides 25x25 mm and a thickness of 3 mm. It weighs only 1.12 kg. The largest mass will have a corner with sides of 200 mm and a thickness of 12 mm - 37 kg. However, even such indicators are much lower than the weight of other metal structures that have the same level of strength.

- Due to the features of the form, the corner is able to withstand a large load. This allows you to use it even when erecting large spans in buildings, such as an industrial warehouse or a production workshop.

In addition to standard sizes, manufacturing companies can manufacture metal corners to order. Of course, if the ordered size can be performed on existing equipment.

How and where to buy?

If there is a need to acquire a steel corner, it is not difficult to find a company that sells them. However, first you need to learn about the reliability of the company. To do this, read reviews. Optimally, if you have friends who have already had to deal with a particular company. Do not conclude a supply contract ahead of time. You can do this only when you find out that the reviews about the company are only positive and you can trust her. This caution is needed in order not to be deceived. If you know that the company is reliable, and the quality of the profiles and the metal itself is at a high level, you can confidently make an order. It is desirable that the company produces a wide range of corners.

Raw materials, construction, as well as dimensional data and material grade must comply with all applicable standards and rules at the manufacturer. Even better if all the requirements are consistent with state standards. If you have chosen the right and the right company, a quality product is guaranteed.

Before buying a corner, it is necessary to consult with a master who understands this matter. After all, the desired choice of the type of corner depends on the features of the application. Even a small error or an error in size will lead to the fact that the entire structure, which is attached with the help of the corners, will not be able to fulfill its direct duty. Accordingly, this will lead to the replacement of the corner. But to do this, you have to disassemble part of the structure, and sometimes even the structure completely. As a result - wasted extra time, money, and sometimes even nerves.

So, we found out what the angle is of a steel unequal assortment. In conclusion, we can conclude that, despite its lightweight construction, the significance of the part in professional construction and in everyday life is hard to overestimate. And it doesn’t matter which corner is a steel unequal, whose assortment is one of the widest, or any other. As you can see, sorting out the varieties of these metal products is not so difficult. When buying corners, pay great attention to whether they comply with the State Standard. After all, those products that do not meet the requirements of GOST have much less reliability and stability. And this means that your design will not withstand the proper loads and will simply collapse.