The temperature effect, even with small deviations from the natural regime for a particular environment, can cause harm to some materials. This does not mean that all objects should have adequate protection, but in some technological areas the availability of such support is very important. For this, a heat shield is used, which forms a kind of insulation. Such protective equipment is used in professional areas of construction, and in industries, as well as in everyday life.

What is a protective screen?

As a rule, such screens are sheets, canvases or panels made of one material. Another thing is that this material itself is a modified base, which is obtained as a result of special production procedures. The most common are molybdenum and tungsten panels, characterized by high thermal resistance. In advanced versions, the heat shield may have a more complex device. Usually these are two sheets that are separated by a gap with the shells - special conical drums. This gap may also be filled in the form of heat-shaving chips. In some cases, powder from the same molybdenum or tungsten is used. A structure is formed that, according to the principle of operation, resembles plastic windows with a heat-insulating vacuum.

Fields of application

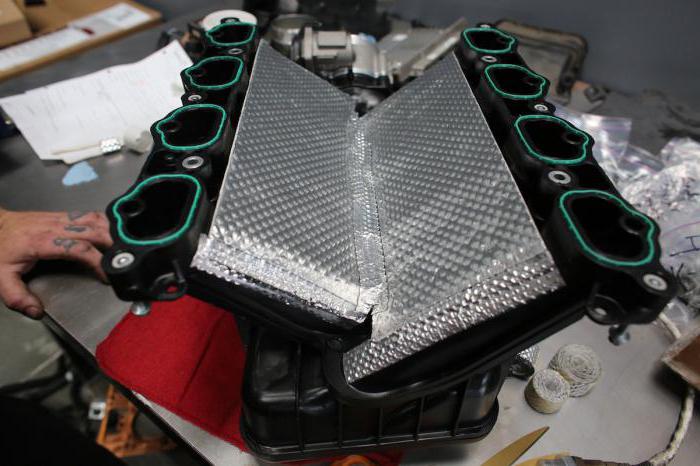

The scope of such screens is very wide. If you do not take into account highly specialized and professional niches, then the most popular will be materials for cars, windows and baths. In the first case, the heat shield of the collector is used, which is a simple metal plate. This is a thin sheet that is usually fixed at four points between the collector and the injector.

In the case of windows, the use of such screens is due to the desire to prevent the penetration of cold into the apartment in the winter. But in such systems, instead of powder, only air acts as a filler. It creates a kind of pillow that provides an additional barrier to the cold. In other words, the heat shield for the installation of windows acts as an external insulator, which is effective from the point of view of saving space in the room itself. As for the bath rooms, the screens in them act on the insulation of specific objects that are sources of high temperatures. In particular, boilers and furnaces are protected by insulators, preventing dangerous thermal effects on nearby objects.

Key Performance

Manufacturers strive to provide screens with three categories of performance. First of all, it is heat resistance. This quality not only means that high temperature waves will not propagate beyond the barrier, but also eliminates the risk of destructive effects on the material itself, of which the heat shield and its filler are made. The second category represents mechanical protective properties, the presence of which ensures that the material will not be damaged, except for heat, also physical effects. For example, the same metal is resistant to accidental impacts and cuts. The third group of properties suggests the presence of other insulating properties. It can be, for example, vapor barrier or noise reduction function.

Characteristics of protective screens

When choosing a screen, you should mainly rely on the ability of the material to provide the aforementioned heat resistance. Resistance to specific temperatures is a basic characteristic. So, tungsten panels withstand temperatures of 3300 ° C, but as this indicator increases, the melting process begins. In turn, molybdenum copes with its function at a temperature of about 2610 ° C. But it should be remembered that peak temperatures are not at all a recommendation for use in such conditions. For example, manufacturers recommend using the same tungsten with molybdenum under conditions of 1300-1400 ° C. In addition, the selection takes into account the dimensions that the thermal screen has in a particular modification. In height, they can have 100-150 cm, in width - 50 cm, and the depth rarely exceeds 10 cm.

Varieties

Screens are distinguished by design parameters, properties and applications. Moreover, all three criteria are mutually dependent and determine each other. For example, in providing windows for winter time, the most difficult functional barrier in the device with a tungsten filler, which has the largest size, can be used. Specialized heat-resistant panels are used in the arrangement of boilers and furnace structures. On the other hand, the heat shield of the exhaust manifold is the simplest solution, which is due to the tight installation conditions and relatively modest thermal loads.

Installation Nuances

There are various installation methods, which are determined by the design of the screen itself and the installation conditions. The most reliable method provides for the initial installation of frames on which the screen is subsequently mounted or fastened by means of brackets or screws. It is important to consider the possibility of future dismantling of the structure. This is especially true for window thermal barriers, which are used only in winter. Again, the protective heat shield for the car provides the most affordable installation method. Typically, manufacturers provide holes in the metal sheets and attach kits with hardware to fix the product. Another thing is that the installation site itself near the same collector must match the screen configuration.

Conclusion

In each case, when choosing a heat shield, an individual set of qualities should be considered. Moreover, resistance to thermal stress is not always decisive. That is, modern materials and modified panels made of molybdenum and tungsten, even in budget versions, are able to cope with most thermal loads of a domestic nature. Much more important is structural compliance with the installation site. For example, the thermal screen of the windows should be designed not only to cover the area of the frames, but also withstand a certain technological indent. Even more difficult is the choice, if necessary, of dense insulation of the fireplace or stove. In such cases, they often resort to services for the manufacture of screens for special orders. The same, by the way, applies to protective devices for automobile collectors.