The compressor is a universal unit, which has found quite wide application, both in large-scale production and in small workshops. It is also installed on various cars and special equipment. That is why the question of how to create a compressor with your own hands from a Zilovsky compressor is of great interest to many masters who want to save on the purchase of this device.

Household purpose

To begin with, it should be said that such products will not be distinguished by high productivity, and their manufacture can be expensive. However, there are a lot of applications that make you look for material on how to make a compressor yourself from a Zilov compressor.

- First of all, such a device is perfect for inflating the tires of a car.

- Also, such a unit can be used to work with some pneumatic tools of low power.

- Most often, these products are used in workshops for applying paint to the surface. The fact is that with a surround receiver, they can work for quite a while and create the pressure necessary for this.

- Some experts use such units in blacksmithing and in other industries. The main thing is that the technical characteristics correspond to the given parameters.

Car compressor

Novice masters often ask the question of why this particular part should be purchased in order to create a compressor with your own hands. Zil 130 they consider a morally obsolete car, and the units that are installed on it are worn out. However, it is immediately worth noting that in our country it is this part that is easiest to find, and its cost directly depends on the condition. At the same time, the simplicity of manufacturing this unit allows for elementary repairs and greatly simplifies maintenance.

It is also much easier to make a compressor with your own hands from a Zilovsky compressor than to use other products of this type for this. To perform elementary tasks, it will practically not even need to be redone. However, if long-term use or heavy loads are required, then some refinement will need to be done.

Necessary equipment

To create a compressor with your own hands from a Zilovsky compressor, it is necessary to solve the problem of transmitting torque to the unit itself. You will also need an engine of a certain power and with a specific number of revolutions. Therefore, certain purchases will be required.

Special attention should be paid to the receiver. It is selected in accordance with the tasks assigned to the product. At the same time, a manometer and a safety valve are installed on it, which will be responsible for the necessary pressure.

Torque transmission

When a compressor is made by hand from a Zilovsky compressor, a very important decision must be made about how the power will be transferred from the engine to the unit itself. At the same time, some masters prefer to connect directly, believing that in this way they will not lose the number of revolutions and power. However, it is worth remembering that for such methods for implementing compounds, you need to have a fairly powerful engine. Therefore, they often use a belt drive.

When they do the compressor with their own hands, they usually try to connect the Zilov compressor to the engine through a gearbox. So you can get a pretty good effort at the initial start-up or in the presence of pressure in the receiver. However, the cost of a good gearbox is quite high, and the option with a belt drive can be considered the most optimal.

Engine

If we assemble the ZIL 130 compressor with our own hands, it is very important to choose the right power unit, which will be as close as possible to the operating parameters of the device. In this case, they usually look at the speed of rotation. It should be at least 2000 rpm, since it is this parameter that will allow you to create maximum pressure and enable the design to work in a gentle mode.

To the selection of power fit separately. The fact is that the cost of an electric motor very often directly depends on this parameter. It is generally accepted that for such compressors a power of 1 kW is sufficient. However, this justifies itself if the unit is planned to be used for a short time and without heavy loads. Therefore, more often they use more powerful products.

Receiver

They usually try to make a typical iron-based compressor from ZIL 130 compact and mobile. Therefore, the use of large and surround receivers simply does not make sense. Also, do not purchase these elements of the unit separately, since you can always create them yourself. For this, you can use almost any metal container. In this case, it is best to use gas cylinders or old fire extinguishers.

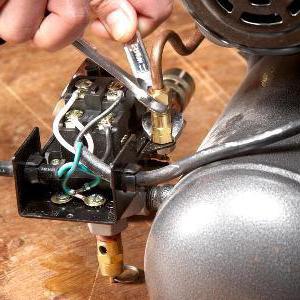

It should immediately be noted that further refinement of the receiver will be required. A pressure gauge and pressure regulator will need to be installed on it. Usually a separate unit with a gearbox is purchased, which is installed at the entrance to the tank. It is also very important to install a back pressure valve. It is tuned to the optimal operating mode of the future product with a certain margin of 10-15%.

Compressor revision

Even if you plan to make a regular garage compressor from a ZIL compressor, the unit itself will need to be slightly modified.

- First of all, it is worth creating cooling. The fact is that such units in the process of their work are very hot and as a result of this, not only performance decreases, but also the service life. Therefore, the connecting rods should be drilled, and an oblique tube is installed in the bottom cover.

- To control the oil level, it is necessary to install a transparent filter at the exit from the crankcase. It also makes sense to put a dehumidifier, which can be made independently from a small fire extinguisher.

- Separately install and a tank with oil. At the same time, it is immediately worth noting that it will be used as an expansion tank and will help normalize the pressure in the system.

To date, there is simply a huge number of various improvements that are aimed at increasing productivity and lifetime. All of these usually relate to a lubrication and torque transmission system . However, the final choice always depends directly on the destination of the final product.

Assembly

First, it is worth making a bed on which the compressor will be installed with your own hands. ZIL 130 has certain seats for this unit, which must be transferred to the frame. So you do not have to make additional holes in the compressor itself, and you can use an additional depreciation system.

Next, the engine is mounted on the bed. In this case, the fixation is carried out in a rigid position, at a distance necessary for the implementation of the transmission of torque. The receiver and other items that can be connected through hoses can be positioned separately. Sometimes they are easier to connect at the place of work, so as not to burden the frame itself.

Recommendations of specialists

- If the compressor is made from Zilovsky, the tools will need to be selected very carefully. You will need to have a drill, a welding machine, a set of keys and much more. There may also be situations when some types of work are easier to do in the factory or with the help of special machines.

- It is best to use rubber gaskets or inserts to create shock absorbers when fixing all units to a bed or a supporting frame. However, it is worth remembering that with intensive use they wear out quickly and you always need to have spare ones.

- When buying a compressor, you need to be very careful, because the appearance of the product does not indicate the condition of its internal components and assemblies. Checking the product on site simply does not work, which means that such a purchase should be made only from trusted sellers.

- If you do not solve the problems with overheating of the compressor, then it must be operated in a gentle mode. So it will last much longer, although this can cause some inconvenience in the work. That is why they select the unit for specific needs.

- You can install a manometer on the product with special contacts that are connected to the electric start circuit of the engine. This automates the operation of the device, and will also reduce the likelihood of rapid overheating.

- The electrical circuit for connecting the compressor to the electric circuit directly depends on the type of motor selected. In this case, do not come up with workarounds for starting the primary winding so as not to lose power. This will affect the operation of the product in the presence of residual pressure in the receiver, even if there is a check valve and a fairly powerful engine.

Conclusion

When assembling a compressor from Zilovsky with your own hands, it should be remembered that this work will require the performer to be skilled in handling various tools and to observe the technique of processing all kinds of details. It is also worth remembering that the purchase of certain units will lead to costs, which means that before you start work, you should carefully evaluate all the costs and compare them with your capabilities. The fact is that with intensive use of such a compressor, it only lasts for a couple of years.