Modern gas equipment in heating systems involves the use of a wide range of pipeline valves. These are means of regulation, protection and control, ensuring stable and safe operation of the target unit. So, a new generation of valves is an electromagnetic gas valve designed to distribute and regulate the flow of the working mixture.

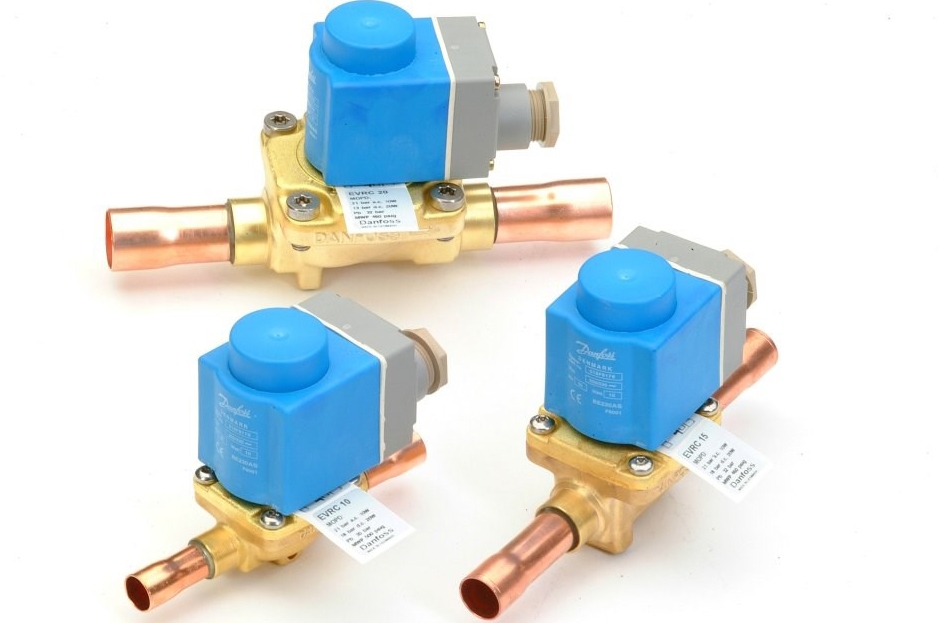

Fixture design

Solenoid valves are also called solenoid valves, since the solenoid in the form of a coil forms their base. It is enclosed in a metal case, complemented by a lid and outlet openings. In addition, the working structure is made up of pistons, a spring unit and a rod with a plunger, which directly control the gas solenoid valve. The device of the coil may differ depending on the type of medium and its pressure, but most often it is a winding with a high-quality enamel wire in a dustproof housing. The cores are made of electrical copper.

Depending on the type of equipment, different configurations of the connecting system can be used. For geysers, a flanged or threaded pipe interface method is usually used. The network connection in the case of household circuits is carried out through a 220 V plug. In the future, the electromagnetic gas valve can be supplemented with auxiliary fittings and control and measuring devices.

Operational properties of materials

Since valve valves are initially oriented to special conditions of use, special plastics are used to base the design. For example, EPDM provides the device with resistance to chemical attack, aging and pressure drops. With this design, the valve can be used in temperature conditions from -40 to 140 ° C, but it is not recommended to use it in gasoline and hydrocarbon environments. Another modern variation of polymer alloy is PTFE. It is polytetrafluoroethylene capable of withstanding high concentration acid mixtures. In this case, contact with aggressive gas environments and operation in the temperature range from -50 to 200 ° C is allowed. It is not recommended to use PTFE polymer in conditions of risk of contact with trifluoride chloride and alkali metals. At the same time, protective qualities are not always the main requirement for the electromagnetic valve. Gas shutoff valves for the same household supply networks may well be made of inexpensive elastic polymers like nitrile butadiene with a rubber base. This material copes well with the maintenance of butane and propane mixtures, but at the same time it is afraid of strong oxidizing agents and ultraviolet radiation.

The principle of operation of the solenoid valve

The state of the valve is affected by an electromagnetic coil, the pulses of which actuate the locking elements. The static position of the valve is characterized by its closedness. In this position, the locking membrane or piston element is tightly pressed against the output circuit, preventing the passage of the working mixture. The clamping force is provided by the spring block and direct pressure from the gas mixture from the passage side. On the main pipe, the electromagnetic gas valve is additionally locked by a plunger until the voltage in the coil changes. At the time of exposure to a magnetic field in the solenoid, the central channel begins to open, where the spring-loaded plunger is located. As the pressure balance changes from different sides of the valve, the piston group with the membrane also changes its state. In this position, the valve is located until the coil voltage decreases.

Features of Normally Open Valve

The principle of operation of the most common statically closed structure was described above. In the case of a normally open valve, regulation is different. In the normal position, the locking elements provide free passage for gas mixtures, and the supply of voltage, respectively, leads to closure. Moreover, maintaining a long closed state for security purposes is only possible with long-term and stable support of a given voltage. An even more functional solenoid valve for a gas boiler does not act directly, but with a technological pause. For a short period of time, the system evaluates whether other safety conditions in the mixture supply circuit are met. The voltage in the coil as such does not initiate valve closure. But if indirect conditions are satisfied, then it works automatically. The decisive factor, in particular, can be a certain voltage value, the same stability or a given amplitude of pressure drops.

Types of device

Valve regulators for geysers are distinguished by the number of output channels. Usually use two-, three- and four-way models. The basic two-way version has an input and output channel, and during operation, respectively, serves to feed and block the connecting node. As design complexity increases, the number of inlets increases. The three-way gas solenoid valve, in particular, provides not only the throughput, but also the redirection of the working medium to one or another circuit. Devices with four channels do operate on the principle of a collector, distributing gas along different supply lines.

Conclusion

In choosing a suitable stop valve, it is important to consider many technical and operational parameters. At a minimum, you should rely on the structural and electrical characteristics that will allow you to correctly integrate the device into the target channel. As for the protective qualities, it is advisable to give preference to electromagnetic valves for a geyser with an insulation class IP65. Such products are dust, moisture and shock resistant, which ensures a long service life. With regard to the configuration of the connection and the principle of operation, the choice should be made based on the nature of the operation of the column, gas supply volumes and other nuances of the equipment.