The cost of overlapping houses for any purpose usually reaches 50% of the cost of a typical residential building. The technical condition of these structural elements is one of the main factors that determine the need for reconstruction of civil and residential buildings.

Replacing floors is a fairly expensive and very time-consuming process. In value, it reaches 20% of the amount of one-time reconstruction costs. These works provide for a whole range of measures that are aimed at restoring the bearing capacity of the floor and individual parts.

What involves reinforcing floors

Reinforcement of floor slabs may imply a decrease in load and ensure reliability for the duration of the work. The cross-section of the supporting elements should be increased. The design should be changed.

Recovery and reinforcement may include the identification of safety factors. The design is recalculated according to new standards, which take into account the nature of the work of the ceiling. Depreciation during such work should not exceed 40%. The design may be overloaded. To do this, heavy backfill and grease are replaced by modern materials, which reduce the dead weight of the floor. In this case, wear at the stage of work should not exceed 60%.

Additional measures

Reinforcement of floor slabs may imply an increase in the cross section of structural elements. Manipulations involve the attachment of additional elements to existing sections. These nodes will take on part of the load. In the case of reinforced concrete floors, clips and metal clamps are installed. In the first case, such additions are also called shirts.

Adding Items

Reinforcement of floor slabs is sometimes accompanied by the inclusion of new elements in the work. In this case, the beams that are on the supports are brought up. They are installed between existing structures. New structural elements can absorb the load partially or completely. To achieve the goals, structural designs can be changed. The efforts are redistributed, in some cases the spans are reduced.

Use of props

Sometimes additional supports can be installed. Depreciation should vary from 40 to 60%. Reinforcement of floor slabs by this technology is expressed in the transformation of the beam by one span into a multi-span continuous structure. The technique may involve the installation of stressed metal struts and puffs that must be prestressed.

Work on strengthening monolithic and precast plates

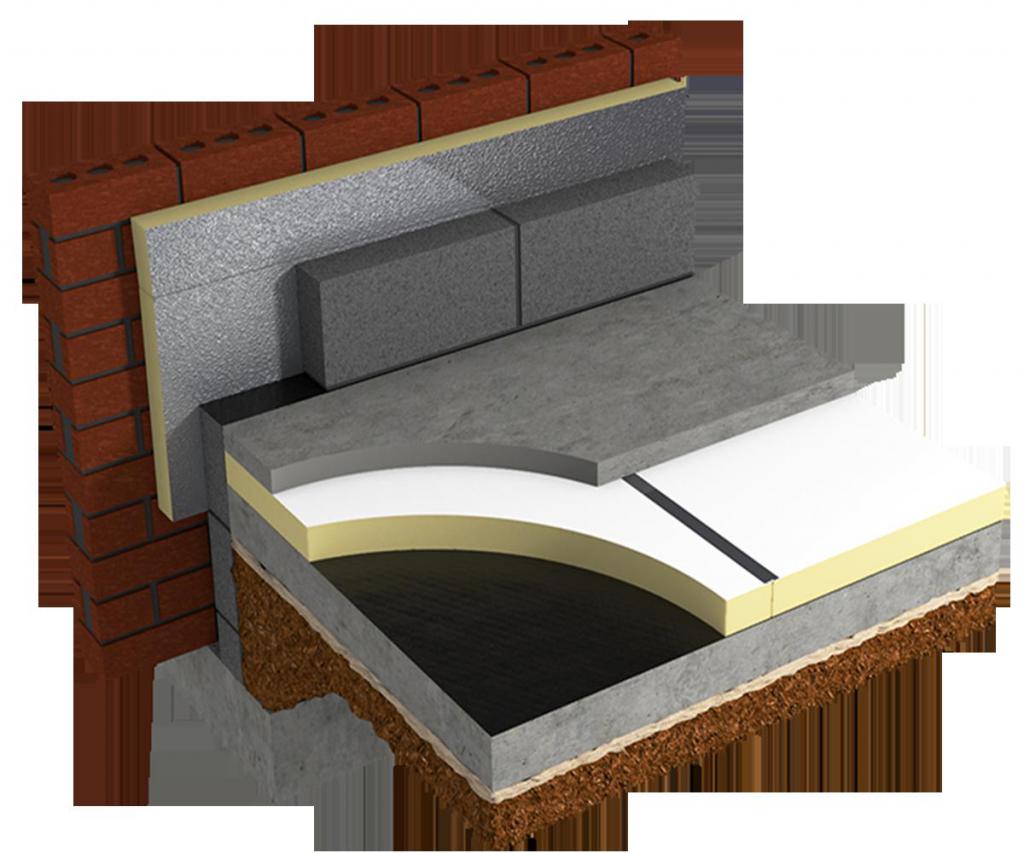

Monolithic slabs are enhanced by building technology. An additional slab is concreted on top of the existing one. The supports are installed in the form of metal or monolithic reinforced concrete beams.

Reinforced concrete products of floor slabs can be prefabricated reinforced concrete. Such structures are hollow and reinforced using the same voids. In the zone of the channel, a shelf breaks through from above, where the reinforcing cage is installed. Work can only be carried out on the supporting part of the plate. In this case, the frames will be located on the span. Sometimes there is a need for amplification along oblique and normal sections. The frames in this case will be located along the entire length of the plate.

When reinforced concrete products are reinforced with a floor slab using this technology, the channel is filled with a plastic solution closed on fine-grained gravel. The slab must be designed with fittings in mind. If you have to work with a multi-hollow precast plate, then you can carry out monolithic channels. This technique is used in the presence of cracks in the wall between the voids, as well as if you want to increase the bearing capacity of the structure.

Training

The reinforced concrete plate is amplified according to a certain algorithm. To begin with, the surface should be cleaned of floor elements. A groove penetrates along the slab, the width of which can be from 70 to 100 mm. The surface must be blown with compressed air. Following are installed reinforcing cages, oriented vertically. It will also be necessary to install a reinforcing mesh. The next step will be the lighthouse rails. Next, you can lay concrete with a seal.

The reinforced concrete plate can be reinforced from below with metal ties, which are embedded in the supporting parts of the flooring and panels. Beam ceilings made of reinforced concrete can be strengthened by reinforcing and concreting beams. However, most often they use trusses, which are located on both sides of the beam. From below, these elements are pulled together to give them tension and turn them on.

Using sprengel

If reinforced concrete floor slabs are reinforced by the method of transverse tightening of the truss, this will not allow to obtain the desired effect, which will cause concrete to crumble on the side faces of the beam. For this reason, today are used sprengels, which are made in length and stretched in the longitudinal direction.

Alternative solutions

Reinforcement will be effective if you use the articulated rod chain. This technique in nature can be compared with reinforcement using sprengels. The joints will be articulated. In the chain, it is necessary to make intermediate nodes, the number of which will depend on the span of the beam. This method of reinforcing floor slabs involves the installation of suspensions from different sides of a reinforced concrete beam. The connection is from below.

When the chain is pulled, the middle suspension is tensioned. For uniform reinforcement, sometimes it takes several attempts to tension the suspensions. The required degree of unloading or the magnitude of the gain can be determined taking into account the actual strength. If you chose this design, then you can improve its work by bringing the channel under the suspension. At the ends of the beam, it is necessary to install tensioned clamps. Suspension work can be combined with a channel-lining. At this stage, it is necessary to eliminate the compression of concrete under the suspensions, while the clamps will strengthen the beam by cutting force.

Carbon fiber use

Reinforcement of floor slabs with carbon fiber is a new technique for Russia, which was first implemented in 1998. The technology consists in gluing on the surface a high-strength material, which takes part of the effort, increasing the bearing capacity of the element. Adhesives are structural adhesives based on epoxy resins or mineral binders.

If you want to reinforce hollow core slabs , you can consider carbon fiber, the physical and mechanical characteristics of which are quite high. This allows you to increase the bearing capacity of the structure without losing the useful volume of the room. The own weight of the building will also not be increased, because the thickness of the reinforcing elements used varies from 1 to 5 mm.

Carbon fiber is a material, not a final product. Materials are made from it according to the type of nets, lamellas and carbon tapes. Coating plates (GOST 28042-2013) are reinforced by gluing carbon fiber in those places where the zones are most stressed. This is usually the center of the span at the bottom of the structure. Manipulations can increase the bearing capacity of bending moments.

To solve the described problems, you can use different types of carbon materials. If we are talking about beams, then they are strengthened in the support zones, where it is possible to increase the bearing capacity. It is in these areas that transverse forces act. In this case, U-shaped clamps in the form of stickers are used.

Lamels and tapes are sometimes used in combination, because the methods of their installation are similar. But if you decide to use carbon nets, this will exclude the use of lamellas and tapes, because you will have to carry out wet work.

Coating plates, GOST of which was mentioned above, are enhanced by technology, which provides for the marking of the structure at the first stage. It will be necessary to outline the zones where the gain elements will be located. These areas are cleaned of decoration materials, cement milk and dirt. You must reach a large concrete aggregate. To do this, use an angle grinder or a sandblasting machine.

The compatibility of the design with the amplification elements will depend on how well you prepare the foundation. Therefore, at the preparation stage, it is necessary to make sure the surface is even, its strength and the integrity of the materials in the base, as well as the absence of dust and contaminants. The surface should not be wet, and the temperature should be within acceptable limits. Carbon materials are being prepared. They come packaged in polyethylene. It is important to exclude contact of the elements with dust, which after grinding concrete a lot. Otherwise, the elements cannot be impregnated with a binder.

You will have to cover the working area with polyethylene, which makes it convenient to unwind the carbon material to the desired length. When cutting, you can use a clerical knife, an angle grinder or metal scissors.

Calculation of reinforced concrete structures before amplification

Verification calculations consist in comparing the forces in the elements with their bearing capacity. First you need to determine the actual forces in the sections. Dimensions, rigidity, value, location and nature of the load are taken according to the results of the survey. At the final stage, conclusions are drawn and recommendations for strengthening are made.

Of particular importance is the choice of resistance of the structure and reinforcement. These values are taken according to the results, which must comply with the rules. The cross-sectional area of the reinforcement should be taken in view of its reduction due to corrosion. When performing verification calculations, you must perform static calculations. Bending and twisting moments, transverse and longitudinal forces must be determined, taking into account the points established by the survey.

When there is a change in the ratio of span and reference moments, it is necessary that in the beam sections the sum of the span moment and the proportion of reference moments equal the moment in a single-span beam. This conviction can be expressed as follows: la M lb M0 = M pr + MA + B, (1.14). Here M0 is the bending moment determined for a single-span beam; but M pr is a bending flyby moment taking into account deformations. The abbreviations M A and M B denote reference moments in the diagram. Whereas a, b is a step to the section from the left and right supports. The span here is indicated by the letter l.