Expanded polystyrene foam is produced using a special technology. The manufacturing process is divided into several stages. The material for production is suspended expanded polystyrene.

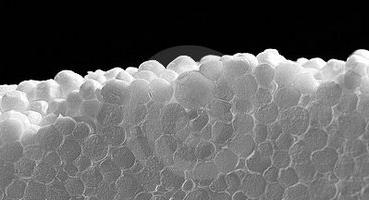

At the first stage, a natural substance, pentane, is used. This substance is highly degradable in soil, water and the atmosphere. Under the influence of pentane, foaming of polystyrene is carried out. Then the granules are heated. For this, water vapor is used. The result is a uniformly foamed mass. This mass has a fine closed-cell structure. In a cubic meter of this material, the air concentration is ninety-eight percent. The air is enclosed in several billion closed cells. Foamed polystyrene foam has a special internal structure that provides low thermal conductivity of the material. The level of thermal conductivity of the material is similar to that of stationary air.

Foamed polystyrene foam made by the above method, when cooled, solidifies and is a rigid mass. This mass includes closed cells filled with air. The quality of the material obtained depends on the equipment that was used during production. Of no less importance is the raw material from which

polystyrene foam is made

. Foam blocks - are products for the production of which the material in question is used. At the fault, the foam looks like balls glued together.

The material is used as insulation. Expanded polystyrene is characterized by low thermal conductivity, the level of which increases with increasing density. The material is moisture resistant. Expanded polystyrene foam does not swell in water and does not dissolve in it. The presence of an unrelated structure of the cells in which air is contained almost completely prevents the penetration of moisture. Even if moisture penetrates between the fused granules, the water will quickly leave the material without having a detrimental effect on it. Being in conditions of high humidity does not adversely affect the material - it does not change either its size, or mechanical strength, or appearance, or insulation characteristics. If during production the technological process will include optimization of the molding mode, which allows to increase the level of fusion of granules, then water capture can be significantly reduced.

In the vapor phase, liquid may seep into the polystyrene foam. Steam will exit and enter the material at the same speed. If it goes into liquid form, then difficulties may arise.

Among other qualities, the material is resistant to the influence of mineral aggressive environments. Expanded polystyrene is compatible with gypsum, cement, clay, bitumen, lime and other materials used in construction and decoration. The material is also resistant to the influence of a number of chemical compounds.