In various areas of industry, a necessary condition for the development and production of metal products is a comprehensive study of their microstructure. At different stages of production, technologists examine the characteristics of raw materials, billets, parts and final products, which allows us to successfully improve the properties of materials and timely detect defects. In recent years, the tasks of such studies are increasingly entrusted to optical technology and, in particular, to a metallographic microscope, which is used to study opaque objects in reflected surfaces.

Device purpose

For the most part, such devices are involved in areas involving the execution of certain operations with metals. In particular, they are used by geologists, archaeologists, metallurgists and specialists from various fields of instrumentation and electronics, where an accurate analysis of conductors is important. What information does a microscope provide for metallographic studies? This device allows in reflected light to form the structural configuration of the placement of the grains of the material, to fix the presence of foreign particles in it, to determine the characteristics of the surface layer, etc. From the point of view of defectology and non-destructive testing, this is extremely important information that gives an idea of the defects in the external structure of the product with in the smallest details about dimensional parameters, crystalline structure and even some chemical properties. For example, this method of analysis reveals the smallest shells, cracks, imperfections and other defects.

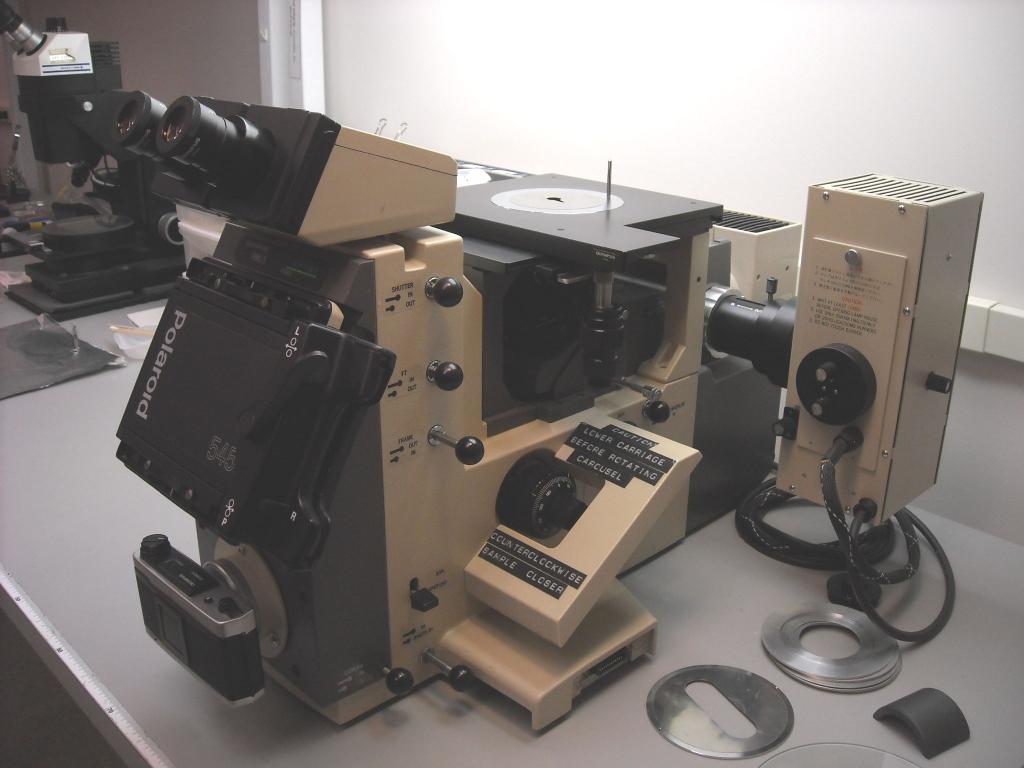

Apparatus design

The basic device of the device consists of three parts, which include a lighting module, a central unit and a table. The lighting part is a lamp or a lantern, which is fixed on an adjustable swivel bracket, and also has its own energy supply. The same part of the metallographic microscope includes a group of filters with different colors. As for the central unit, it contains several functional components at once, including a prism optical system, a lighting tube, object tables, regulatory mechanisms, eyepiece nozzles and auxiliary means for organizing technical operations during operation. All of the above infrastructure is located on the carrier base - the microscope table, which contains an optical bench and various kinds of drawers with cabinets in which the apparatus accessories are stored.

Operating principle

The main task of the device is to process the parameters of radiation reflected by the surface of the object. To do this, the aforementioned optical system is used, which captures the slightest changes in the aperture diaphragm against the background of the regulation of the object's lighting parameters. In a sense, the working factor of measurement is the course of the rays, which manifests itself differently in bright and dark fields. For example, when examining in a bright field, the rays coming from the lamp pass through the diaphragms (field and aperture) and are sent to the reflective plate. The latter, in turn, reflects the characteristics of the investigated structure, partially redirecting light to the target product using the lens.

When observing objects in a dark field, an optical metallographic microscope interacts with a parabolic specular-reflecting surface, an annular diaphragm, and a hinged lens. The extreme beams of radiation, bypassing the diaphragm, are directed to an annular mirror covering a plate with a reflector. From this moment, the mirror begins to reflect light on the condenser with the redirection of the rays into the plane of the object. The image is formed on the basis of the characteristics of the reflected rays passing through the lens and falling into the optical tube.

Characteristics of a metallographic microscope

The working process of the device is characterized by two groups of parameters - these are the indicators of the lens and eyepiece. The main operating parameters of the lens include:

- The magnification ratio is from 11x to 30x in bright field conditions, and from 30x to 90x in studies in a dark field.

- The numerical aperture is from 0.17 to 1.3.

- Focal length - an average of 2.4 to 23 mm.

- Free distance - from 0.13 to 5.4 mm.

In the case of the eyepiece of a metallographic microscope, it is worth highlighting two key characteristics:

- Focal length - from 12 to 83 mm.

- The linear field of view is from 8 to 20 mm.

User's manual

Before using the device, it is necessary to adjust the bed frame or the working platform of the structure, open the aperture diaphragm, adjust the mechanical mounting units and move the analysis collector to the lamp. If you use a portable metallographic microscope, then the optimal combination of eyepiece and lens settings will help to achieve software, since portable device models provide the ability to connect to computer stations directly in the laboratory. One way or another, by the beginning of work it is recommended to set the magnification scale in the range from 500 to 1000 apertures. Next, you can move on to sofetofilters, which are selected according to the characteristics of achromatic lenses. In this case, the universal solution will be the correction for the midtones of the visible part. Only a yellow-green filter is not compatible with apochromats. After tuning, the process of optical processing of the formed image data is started, the graphic materials of which are subsequently sent for decryption in accordance with the analysis tasks.

Conclusion

The technology of metallographic research has a rather narrow specialization, which does not reduce the enormous value of this method of studying surfaces. To meet consumers in the form of industrial enterprises with their laboratories are the developers of the device themselves, improving its operational qualities. For example, the METAM-P1 domestic metallographic microscope, worth about 13 thousand rubles. It is characterized by a rich configuration and the presence of modern high-tech functions. It is enough to note its provision with sets of planachromatic lenses and compensation eyepieces with wide optical ranges. And this is just the basic version in one of the families of metallographic aggregate microscopes of the new generation.