As the technical and design performance of boiler equipment becomes more complicated, its functionality expands. In each segment of heating units, pyrolysis models, versions with support for hot water circuits (DHW), as well as systems with the possibility of long burning, are presented today. Obviously, combined boilers also appear , combining the entire list of modern ideas for this kind of technology. In practice, a long-burning pyrolysis boiler with a water circuit gives a lot of advantages to ordinary owners of cottages and country houses who strive to comprehensively provide themselves with heat and hot water.

Boiler device

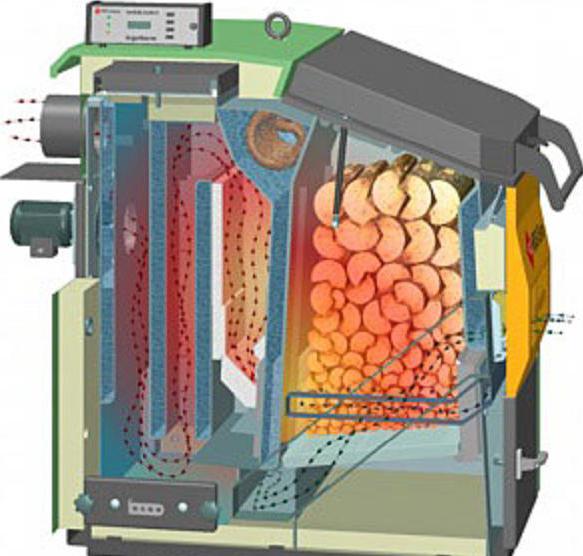

A typical design includes two combustion chambers, a heat exchanger and an ash pan. This is a basic set of functional elements that provide fuel loading processes, heating a water carrier and collecting combustion products. Otherwise, depending on the modification, the device of the unit may change with orientation to certain functional additions. For example, a capacitor, which is a tank with thermal insulation, can be further integrated. It accumulates thermal energy for its subsequent return to the water circuit.

A mandatory part of the technical infrastructure of the boiler is the chimney system. This is a channel for the removal of gas combustion products, the operation of which is characterized by draft - that is, the speed of smoke removal. Using a special damper-gate, you can adjust the throughput of the chimney, which is associated with a pyrolysis boiler for long burning. Reviews note that it is very important to maintain a balance in regulating smoke removal volumes. The fact is that boilers with long-term combustion of fuel are characterized by a long and dynamic process of operation, therefore, during the entire session, multiple adjustment of the channel capacity may be required. Observance of the balance is required so that the air masses do not “walk” in the chimney, and the exhaust gases are stably out.

The principle of operation of the pyrolysis system

The concept of pyrolysis heating devices is quite simple, but in practice gives a significant advantage in the form of increased efficiency. To begin with, it is worth emphasizing the difference in the design of such boilers from the technical structure of conventional solid fuel systems. As mentioned above, the boiler has two combustion chambers - this is the feature of the equipment. One performs the traditional task of organizing a place for burning fuel, and the second just provides the effect of pyrolysis. What does it consist of? If the first chamber extracts energy, for example, directly from firewood, the second processes the gas released during the primary combustion. Unlike the first stage of combustion, the pyrolysis process involves mixing oxygen to increase the efficiency of thermal energy storage. In essence, the principle of double processing of the same batch of fuel is being implemented, which, undoubtedly, has a positive effect on saving and increasing the productivity of the boiler.

The principle of operation of long burning systems

Unlike the pyrolysis system, the idea of maintaining long burning does not require a fundamental change in the design of the unit. However, there are still changes in the parameters. First of all, such a boiler is equipped with a large combustion chamber. That is, in the combined version, the burning of firewood can be carried out in a massive compartment, and the combustion of gases in a small adjacent firebox. For example, if conventional boilers have chambers 30-50 cm in size, the concept of long-term combustion will require the use of at least 60 cm fire chambers. What is more important, the device and the principle of operation of pyrolysis boilers are guided by the wide possibilities of regulating the combustion process. This is achieved through a more functional, and sometimes automated, gate system, that is, a regulator for the throughput of the chimney. This mechanism is responsible for the intensity of combustion by reducing or increasing oxygen tolerance. The advantages of this system include the possibility of rational heat consumption from one masonry and the absence of the need for frequent updating of fuel material.

DHW organization in the boiler

The hot water preparation infrastructure in the equipment is formed using three components - a heat exchanger, a boiler and circulation channels. In the heat exchanger, water is directly heated under the influence of thermal energy, which is generated in the process of fuel combustion. By the way, the use of the boiler specifically for the hot water function in some systems with automatic control allows you to immediately turn off the equipment immediately after bringing the water temperature to the desired mode. Ready-to-use water is sent either to the boiler, or immediately along the contours to consumers. A modern solid fuel boiler with a water circuit and a boiler allows you to contain about 30-50 liters of hot water for a variety of needs. If more capacious storages are required, then it is worth initially selecting individual boilers that are not included in the unified boiler design, but are connected through their communication channels. Such a tank can contain up to 200 liters, and industrial models - about 500 liters.

Equipment performance

Directly, the heat volume is determined by the power of the boiler. The initial bar corresponds to 3-5 kW. This power indicator is enough to service small rooms - for example, cottages. To use the equipment as part of a home heating system, it is recommended to make such a calculation - 1 kW per 10 m2. So, a 20 kW model is enough to service a house with an area of 200 m2. The parameter of fuel consumption is also important, which will determine the energy efficiency of the unit. An average long-burning pyrolysis boiler with a water-based wood circuit consumes about 1-10 kg per hour. The volume of consumption just depends on the power and, in turn, will determine the frequency of loading of new wood masonry. Also a significant parameter is the diameter of the chimney, which determines the boundaries of the exhaust gas throughput - this value is from 13 to 20 cm

Varieties of aggregates by material

Of great importance, from the point of view of operational reliability and heat transfer, is the material of the heat exchanger. So, cast iron is considered the most durable metal for the manufacture of this functional part - we can say the basis of the boiler. It is not subject to corrosion, resistant to mechanical stress, able to withstand large thermal loads, however, sharp temperature fluctuations can still cause cracking, which will lead to the development of rust. Steel directly competes with cast iron. Due to their ductility, such alloys can also be used in conditions of temperature changes, but a pyrolysis boiler with long burning with a water circuit during operation contributes to the formation of condensate, which leads to the risk of corrosion even under normal operating conditions. There are also boilers with copper heat exchangers, which are good and high thermal conductivity, and no risk of rust. But in terms of reliability and strength, copper is the most losing solution.

Varieties by type of fuel

Most pyrolysis boilers operate on wood. It is this fuel material that allows the double processing of raw materials with the release of large amounts of thermal energy due to wood gas. For this reason, such units are called gas-generating boilers, regardless of the possibilities of using other types of fuel.

Alternatively, consider combined systems using electricity or clean gas fuels. But in this case, when switching to these operating modes, the pyrolysis effect will not work. By the way, even a standard wood-fired pyrolysis boiler provides for the possibility of power supply from 220 or 380 V networks. Energy supply is required for servicing automation or a fan installation, which helps to increase the same pyrolysis effect by pumping oxygen.

Manufacturers

Among foreign manufacturers of thermal equipment, companies like Buderus and Atmos deserve attention. Under this brand, high-quality and durable units for home and industrial use come out. Such equipment is characterized by users as functional, modern and reliable. In the Russian manufacturing sector, a solid fuel boiler with a water circuit is represented by Bourgeois-K and Pechkin. In any case, the engineers of these enterprises demonstrate the most successful developments, some of which are carried out according to European quality standards.

Price issue

The cost of boilers with a pyrolysis effect at a basic level exceeds the standard models of solid fuel units due to the complex design. The minimum price level can be designated within 10-15 thousand rubles. This equipment with a capacity of up to 10 kW is found in the same families of manufacturers "Pechnik" and "Bourgeois-K". In the Buderus line, the price of pyrolysis boilers is much higher - about 100-150 thousand. This is due to an increase in power (up to 100 kW), and to the enlargement of the dimensions of the models.

Accessories and add-ons for boilers

Today, developers of thermal equipment are increasingly turning to automation systems, the level of which can be determined by the user in the process of its design. In particular, gas-generating boilers can be supplemented with temperature control systems, programming panels, heat and moisture sensors, timers, etc.

With regard to structural solutions, you should have in stock plumbing fittings to support the work of water circuits - seals, fittings, adapters and other consumables. For a more thorough control of the operating parameters of the equipment, you can intervene in the organization of the air supply system for more efficient combustion of fuel. Technically, this function is performed by cast-iron grate for boilers, laid over the blower in a special niche. By choosing the design of the desired parameter with suitable hole sizes, one or another level of combustion intensity can be ensured. As an addition, you can buy the boiler mentioned above - depending on the needs, its dimensions and capacity are selected.

How to choose the best pyrolysis boiler?

The optimal choice may be different. To solve everyday problems, you should focus on functional and ergonomic models - with a small capacity from the same Russian companies. They should be easy to operate and practical to maintain. In addition, the price of pyrolysis boilers will be elevated for the average homeowner or summer resident - in the framework of 15-20 thousand, you can find a decent option. However, for industrial type facilities, the power and durability of the units are rather important. And this choice is best made in favor of the products of companies of the Buderus level.

Conclusion

The complexity of the design of boilers with pyrolysis action determines not only the positive operational properties of equipment like high efficiency. The user should be ready to switch to a new fuel supply system and regulate the combustion process. In addition, a long burning pyrolysis boiler with a water circuit requires more thorough maintenance. Some models save owners from cleaning ashtrays, which is an advantage, but breaking a double combustion chamber or reconfiguring the duct will require much more responsible actions. Special attention in maintenance will also require water circuits with a boiler.