The foundation of any structure has to experience tremendous loads. Therefore, in order to withstand them, the foundation must be very strong. The strength of the base depends on the quality of the materials used in the construction. According to experts, concrete base blocks are recognized as the best material for the construction of the "zero cycle". What are these blocks and what are their advantages - more on this later.

Features of foundation blocks

Each basement block is a rectangle made of concrete mix. Moreover, not ordinary concrete is used for the production of products, but heavy - M200 or M100. In the labeling, these materials are marked with the letter "T". Silicate concrete or expanded clay concrete, which are designated by the letters "C" and "P", respectively, can also serve as material for the manufacture of block structures. For the construction of particularly large objects, the blocks are reinforced with the help of mounting hardware.

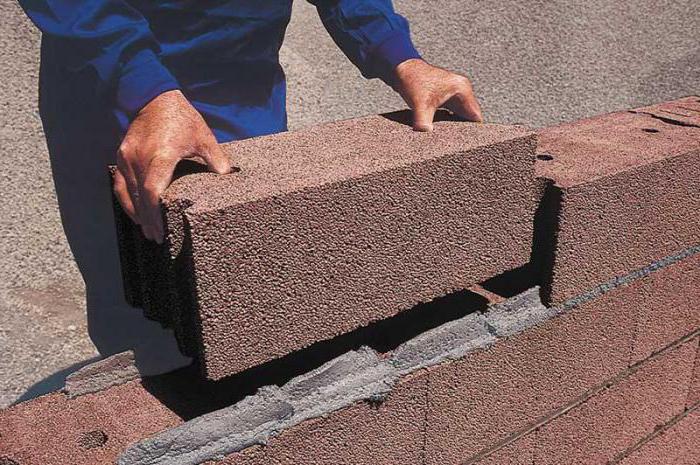

To connect the individual elements in a continuous structure, on each product at the end there are connecting grooves. On the upper surface, the manufacture of two mounting loops is provided - they are needed to move the products for transportation or installation.

According to the requirements of GOST, several types of similar products are made:

- UDB. So-called universal products, the ends of which are open or closed.

- FBP - open, bottom hollow basement block.

- FSB. This abbreviation means that the product is the foundation block for the walls. It has no holes and voids. Designed products for installation in the construction of basement floors, basements and walls.

Disadvantages and advantages of block designs

If we compare block and monolithic products, the former significantly benefit in a number of characteristics:

- The speed of construction. This factor is very important in adverse weather conditions, when there is no time to wait until the concrete hardens in a monolithic base. When erecting a basement from hollow blocks , you can continue building walls immediately.

- Reliability. Products have predictable properties, as their production is carried out according to standards, from the calculation of the parameters of the reinforcing material to the automation of all processes.

- Universality. You can use block elements in the construction of objects of any size, from high-rises to private houses.

- Convenience of styling. Thanks to the standard sizes of mounting loops, end grooves and the blocks themselves, you can easily install the most complex base for any building.

- Stability in extreme conditions. To prevent the construction from failing on acidic soils or permafrost, special additives are interfered with in the solution during manufacture.

- High strength and density. Due to this, plates of this type can be used for the manufacture of load-bearing structures capable of withstanding heavy loads.

Unfortunately, the products have some disadvantages. The most important of them is high cost. The cons include:

- The need to use a crane during construction.

- The need to equip double insulation.

- Performing insulation of the joints between the individual elements.

Plate sizes

Products differ from one another not only by the absence or presence of voids. Each element also has its own size and, accordingly, weight. According to GOST, the length of the products can be:

In this case, the width indicator can be 30, 40 or 50 cm, and the heights 30 and 60 cm. Thus, the size of the basement block can be from 90 x 30 x 30 to 240 x 50 x 60 cm.

Another important factor is the mass of each individual element. Weight depends both on the design of the product itself and on the materials used for its manufacture. For example, a solid cement element with a size of 2.4 x 0.5 x 0.6 m can weigh about two tons, and a claydite-concrete block with the same overall dimensions is 2 times smaller.

Product labeling

All these and other characteristics are encrypted in the marking. For example: 12.4.6-t. The record is decrypted as follows:

- 12 - element length (indicators are converted to decimeters).

- 4 - width.

- 6 - height.

- “T” - solid concrete was used for the manufacture. Its density is 2,200 kg / cu.

Manufacturing technology

Since the main indicator that each base unit must strictly comply with is durability, such production is carried out strictly according to design data, and the ratio of the necessary components is carefully monitored. To mix water, filler and cement powder, forced-type concrete mixers are used. When the concrete mix becomes homogeneous, it is poured into special forms. Before that, deep vibrators are laid in them. Power tools thoroughly compact a semi-liquid substance, after which it is left to solidify for 24-36 hours.

After this, the products are removed from the molds, although they are not yet completely ready. To give the plates their original strength, a protective film coating is applied to each of them. Then they are watered with water. After 7 days, the boards acquire tempering strength, and after another 21 days, the products become 100% durable, after which they can be used in construction.

Note: if reinforcing material was used to seal structures, erecting a basement from FBS blocks, it is imperative to equip them with moisture. This may be:

- Composite mixture based on bitumen.

- Special water repellent.

Application and installation technology

The basement block is indispensable for the construction of facilities that must meet special technical requirements. But the use of plates does not end there. Expanded clay block can be used for even the most complex construction and installation works in industrial, residential or non-residential construction. Products are also suitable for mounting partitions and various ceilings, creating permanent or temporary fencing of large objects.

Assemble the structure as follows:

- First dig a pit.

- Prepare a pillow of sand and gravel.

- Lay the plates, connecting them with cement mortar. To increase the reliability of the connection, reinforcing belts are used.

- They carry out waterproofing work.

- Insulate the structure.

An important detail: the base of the slabs is not a monolithic structure, so it can only be built on reliable soils. Foamy soils cannot serve as a reliable foundation for the building, therefore, it is not recommended to collect the foundation from the plates on them in any case.

Specifications

The main characteristics of the slabs intended for the construction of basement floors are the following features:

- W2 is a measure of the water resistance of a brand of used concrete.

- F200 - frost resistance of concrete.

- 2400 kg / cu m - an indicator of the density of the material.

- 100-110 kg / cubic m is the density of the material.

- B12.5 - an indicator of the magnitude of compression.