Any boiler equipment that is installed at enterprises or in a private home is a source of great danger. A water jacket, which is part of the boiler, is a vessel under pressure, which indicates its explosion hazard. In order to minimize such a risk, modern heat generators and their strapping schemes require the presence of protective devices and all kinds of systems. As one of the simplest and most popular pressure relief valve is used.

Each owner of the boiler equipment described in the article should understand how dangerous the operation of the device can be. That is why when installing the device, it is important to think about the need for a safety valve in the system, which you can choose and install yourself without any assistance. However, it is important to ask the manufacturer whether the guarantee for the units will remain after such work.

Application

In order to understand where to install the described device, it is necessary to understand what the valve is used for. The purpose of the installation is to protect the heating system. With this supplement, you can eliminate the increase in water pressure. It can occur when the coolant in the boiler overheats. This is especially true for those devices that run on solid fuel.

As soon as the coolant reaches the boiling point, vaporization begins, which leads to a sharp increase in pressure in the system.

Need to use

Failure to use a pressure- controlled pressure relief valve may result in ruptures and leaks in the piping system. Most often this occurs at junctions. You may encounter destruction of polymer fittings, as well as pipes. The most dangerous is the explosion of the boiler tank, as well as a short circuit in the boiler room. A small valve, which has a fairly simple design, will help to protect against troubles. Given the moment that the pressure increases to a critical point in the boiler, the safety valve must be installed closer to the device in the supply pipe.

A number of manufacturers of boiler equipment complement the products of the safety group. It includes an automatic air vent, pressure gauge and relief valve. The group is installed directly in the water jacket of the boiler equipment.

What you need to know about usage features

Pressure-controlled safety valve is not always used in systems. For example, when an electric or gas boiler acts as a heat source in a house, a waste device is not required at all. This is due to the reason for the presence of safety automation in these types of heat generators. Among other things, they lack any inertia. Owners of such devices should be aware that when the set water temperature is reached, the electric element or gas burner will simply turn off and the heating will stop almost immediately.

Need to use

A pressure-controlled safety valve is used when a furnace or solid fuel boiler with a water circuit is used. Here, the installation of the described device is required. As soon as the firewood in the furnace burns up, and the coolant in the network reaches a certain temperature, it will be necessary to reduce heating. It is important to close the air in the combustion chamber, this will allow the flame to die out. However, inertia will continue to increase the temperature.

If this process proceeds near the limiting values, then vaporization at such moments is inevitable. We are talking about temperatures in the range of 90-95 degrees. As mentioned above, boiling will lead to an increase in pressure, and the safety valve for the boiler can prevent this. It is designed to automatically open the way for the formed steam, which leaves, thereby lowering the pressure to the standard value. After that, the device will close on its own to come into standby state.

Design Features

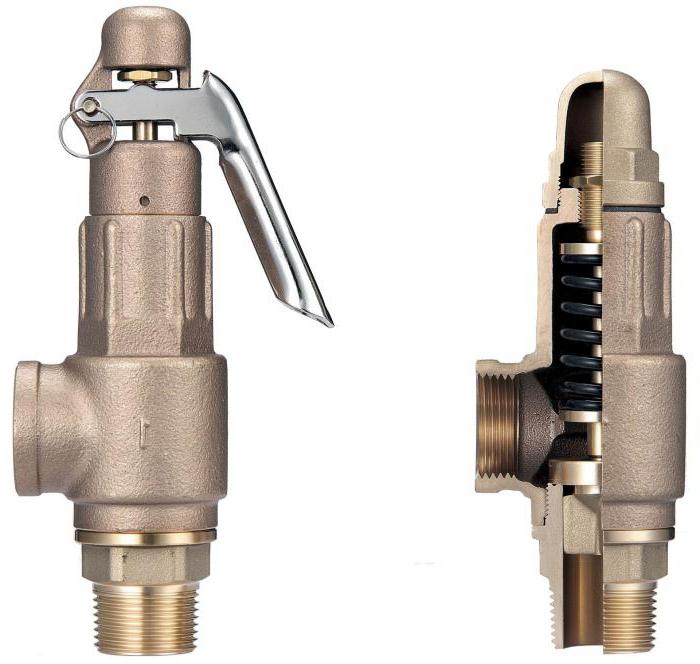

The design of the described addition of boiler equipment is very simple. The body is made using high-quality brass plumbing. In the process, hot stamping is used using 2 cast parts in a semi-solid state. The spring acts as the main working element of the valves. Its elasticity will determine how strong the pressure will be on the membrane. The latter closes the passage out.

In normal position, the spring is in the seat with a seal. The metal washer serves as the upper stop for the spring. It is fixed on the stem, the end of which is attached to the plastic handle. Using it, the valve is adjusted. Sealing elements are made of polymer metals, but as for the spring, it is based on steel.

Principle of operation

The safety valve for the boiler has a very simple design, this also applies to the principle of operation. In standby mode, which is normal, the water parameters are in a certain range. The membrane serves to close the entrance to the inner chamber. After a situation arises that can be called close to emergency, the pressure in the system increases, the mixture of steam and water begins to support the membrane. The pressure force of the liquid overcomes the elasticity of the spring, which contributes to the opening of the membrane. The coolant enters the chamber, and then flows out through the side opening.

A gas valve is simply necessary for a certain amount of water to leave the system, this will lead to a sharp decrease in pressure and the closure of the membrane. As a rule, the mechanism functions perfectly, especially when the heating equipment is operating at the limit and the water temperature reaches 90-95 degrees. The gas valve can operate quite often. In practice, this leads to the fact that it loses its tightness. You may notice this problem when water is leaking.

For reference

If you checked the safety valves and you noticed fresh traces of smudges of the mechanism, this indicates an extreme operation of the heat generator or the presence of malfunctions in the system. The problem may be with the expansion tank.

Installation Recommendations

The installation of a safety valve should not imply the presence of shutoff valves in the place where the pipeline section from the boiler equipment to the valve itself is located. Among other things, it is forbidden to install the device after the circulation pump. A device in this condition will pump a mixture of steam and water.

In order to avoid the possibility of water spraying on the furnace, a pipe must be connected to the outlet of the device, which will discharge emissions into the sewer. If you want the safety valve to be adjusted not only mechanically, but also visually controlled, a drain funnel must be installed on the vertical section of the tube so that the jet break is visible.

Conclusion

Setting up safety valves, their installation and operation is a very simple task due to design features. Experts do not advise chasing a cheap product, therefore, when choosing a device, be guided by its quality and reviews of those who have already tried such a system. The main thing in this business is safety and efficiency.