Ventilated facade technology has been successfully used in construction for several years. Among the target objects can be called business centers, train stations, entertainment complexes and other buildings, the exterior decoration of which has high aesthetic and functional requirements. The cassette facade, a photo of which is presented below, has become a new round in the development of technology for ventilated decoration. This technology has greatly simplified the configuration of the formation of multilayer cladding, slightly changing the rules for its installation.

Technology features

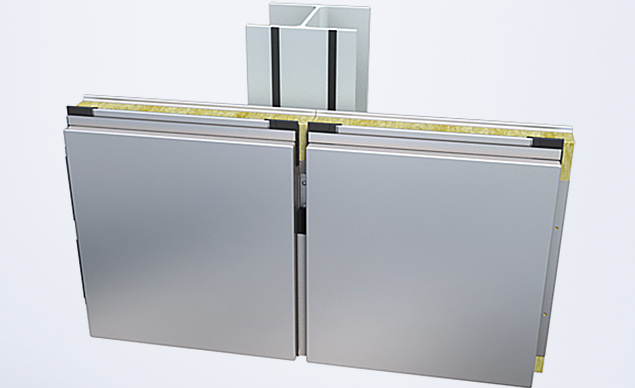

The basic structure of the ventilated facade provides for the use of three main elements - the supporting profile (metal lathing), insulation and external cladding. As the last component, porcelain stoneware tiles are generally used that match the overall design of the building. Installation of such a system is carried out manually in stages, which requires a thorough technological calculation. This approach has been adjusted by cassette metal panels. For facades of this type, functional frame-sheathing plates are used, which perform not only an external decorative role, but also fixing and fixing tasks.

If the porcelain tile panel is completely devoid of any elements for installation and an individual base for fastening should be developed for it, then the metal structures are optimized as much as possible for connection with the basic profile frame. But for fastening to the wall and lathing, sets with anchor bolts, butt elements and supporting clamps are also used. Of course, the central part also retains functionality, allowing you to fill the space with insulating materials, hydro and noise barriers.

Cartridge Specifications

Panels without fail are made of metal with a corrosion-resistant coating. The thickness of the sheets is small and averages from 0.7 to 1.5 mm. A technological gap of 40 to 100 mm is maintained between the wall and the casing. The layout parameters will largely be determined by the type of structure and the height of the building. For example, for objects up to 40 m high, a standard cassette facade is used, the panel dimensions of which can be as follows:

- For the bearing and directing profiles (vertical and horizontal) - 60271 mm.

- For supporting profiles (vertical) - 75x20x0.7 mm.

For buildings with a height of more than 40 m, panels of the following formats are used:

- Bearing and guide profiles (horizontal and vertical) - 60x27x1.5 mm.

- Bearing profiles (vertical) - 75x20x1 mm.

In some cases, additional leveling brackets are used with a length of 125 to 250 mm and a thickness of 1 mm.

The functions of the insulation are usually performed by mineral wool with a density of up to 100 kg / m3 and a thickness of 100-150 mm. By the way, styling can be performed in two layers. If the calculation of conventional ventilation facades can cause restrictions in the depth of the structure due to the thickness of the porcelain tiles (15-20 mm), then cladding from sheet metal provides additional space for technological filling of the niche. The heat insulator is mounted using a plate-shaped glass-polyamide dowel, which minimizes possible gaps between the base and the mounted plate.

Classification of cassette facades according to guides

Sheathing elements can assume a different installation configuration - vertical or horizontal. From the point of view of the ventilation façade concept, this is the basic structure, which is formed by panels fixed with steel rivets with galvanized coating. Particular attention is paid to the gaps, seams and all kinds of joints between the lining components and the fixing parts of the cassette facade. The design technology of the device provides for the preservation of space to compensate for temperature deformations, so they are not completely sealed. In other words, some layers of the structure, like an insulator, can expand under conditions of increasing temperature, and in order to avoid deformation, a technological gap of about 10 mm is left. More importantly, the vertical rails do not have fasteners to each other.

The horizontal rail system is used less frequently and, as a rule, as a complement to the vertical structure. Fastening is implemented using the same additional elements in the form of rivets. The most critical node in such a cassette facade is the convergence nodes of horizontal and vertical guides. It is recommended to use the "overlap" technique, which may require trimming of the side contours. Directly mechanical coupling is also produced by galvanized rivets. Thin metal allows, in particular, to use metalware of 3.2x8 mm format.

Classification by type of load-bearing elements

Guides can be duplicated by the supporting structure, but this is not necessary. In this case, the separation takes place according to the number of levels. That is, as in the layout of vertical / horizontal systems, a combined two-layer version can be implemented, and when the carrier base is installed, both a single-level and a two-level configuration are mounted.

The simplest systems are based on a vertical single-level load-bearing structure. Decorative inserts of the same material used in the manufacture of metal cassettes are superimposed on the visible profile area. The facade, by the way, can be sheathed not only with anti-corrosion galvanized steel alloys (the most reliable option). In some cases, copper and aluminum are used.

As for the two-level carrier system, in it, U-shaped profile elements are additionally superimposed on the vertical base. If oblong cassettes are used with a length of more than 700 mm, an auxiliary PN-shaped profile in the central region of the cassettes may also be included.

Types of Cassettes

Metal panels also differ - in terms of fastening, finishing options, textured and textural qualities, etc. For example, the most affordable elements have a flat surface, are made of anodized thin aluminum and are provided with standard groove assemblies for fixing. In more complex versions, cassette facades are formed from rectangular steel plates, the outer side of which can have various patterns and even 3D visualization tools. In terms of technical design, the variety is small. Most panels at the edges have perforated areas for fixing to the base through hidden hardware. The side mounting method is considered to be a standard, although there are installation methods using universal additional fittings - that is, installation is carried out due to the transition profile lining that joins the panel with the crate. However, the installation technique deserves a separate discussion.

Installation of construction

Work activities are carried out according to a previously prepared project with a technical solution. Further work is carried out in the following order:

- Prepares material with mounting hardware and consumables. Checks the integrity of the elements, their compliance with design requirements and technical specifications.

- The basis for the cassette facade is installed - the installation of guides and profile elements that will form the supporting base.

- Insulation material is laid.

- Panel cassettes are installed.

Initially, the evenness of the target surface is checked using a theodolite, level or plumb. Further points for installation of leveling arms are outlined. Installation of the initial slats is carried out, a system of vertical guides is formed, on the base of which the panels will stand. The insulation is fixed with a special fixing dowel, and in the future its position will be controlled by intermediate guides from the crate system. It is enough to lay the same mineral wool in the prepared niche without rigid fixation.

Fixture of panels is carried out in the direction from bottom to top and from left to right. Particular attention is paid to the installation of the cassette facade in the lower corners. Here, ebbs are used that perform the functions of supporting and correcting additional elements with respect to the entire cassette field. The start bars at the bottom can also adjust the position of the panel rows. In case of deviations, a small space of temperature gaps can be used to compensate. The mounting edges of the cassettes are superimposed between themselves and closed by fastening accessories - bolts, dowels or self-tapping screws. The choice of hardware will depend on the characteristics of the crate and the material of the base to which the fasteners are made.

Rules for the operation of the facade

After installation, a control check of the quality of the fastening, the ventilation system and the integrity of the casing is carried out. In the future, it is recommended to observe the following rules for the operation of cassette ventilated facades:

- It is not allowed to mount equipment and third-party mounting elements to the cladding.

- Risks of water from the roof covering to the niche of the facade are eliminated. For drainage, special trays and drains are provided in a separate order.

- About once every 4 years, planned inspections of the facade structure are organized. In particular, sheathing elements, the state of thermal insulation and fixtures are checked. Moreover, control and verification activities should be entrusted to specialized firms with the appropriate license.

- For residential high-rise buildings from 75 m and public from 50 m, regular monitoring of the condition of the cladding is required.

Cassette-type facade care features

The surfaces of metal panels do not require special care in terms of maintaining technical and physical properties. The material is initially designed for severe conditions of use in contact with atmospheric precipitation, wind loads, etc. However, to maintain an aesthetically attractive surface appearance of cassette panels for the facade, it is recommended to periodically wash with brushes manually. Coarse abrasive products should be discarded. As a cleaning and washing chemistry, you can use ordinary soap or specialized non-aggressive products for metal coatings. Moreover, during care, it is important to ensure that the liquid does not penetrate into the ventilated space - contact with water is harmful for thermal insulation.

Technology Reviews

The concept of a ventilated façade as such deservedly evokes for the most part a positive user experience. If the designer's design advantages can be appreciated by every visitor to a building with such a cladding, then the direct owners praise its technical and functional advantages. These include the same undemanding maintenance, ensuring an optimal microclimate in the premises, maintaining dry walls and, in principle, protecting the foundation of the supporting frame. It is due to the possibility of air circulation that the walls are ventilated and condensate is removed with unwanted moisture.

Of course, there are disadvantages. They are usually associated with the complexity of installation work and unpleasant consequences already during operation. In particular, the smallest errors in the assembly of the cassette facade lead to the appearance of a hum and whistle. So the incorrect air circulation with interference in the design makes itself felt. Not all developers decide to use such a cladding and because of the high cost. Regular finishing in one layer, regardless of the material, will be cheaper and many are ready to compromise on the functional advantages of the ventilation façade as such. Another thing is that replacing porcelain stoneware with metal panels, in addition to facilitating installation work, still allowed to reduce the cost of the structure as a whole.

Conclusion

The problems of using new construction technologies in Russia are often caused by the low qualifications of their contractors and the unsatisfactory quality of building materials. In part, this also applies to the technology under consideration, therefore it is initially important to turn to trusted companies whose specialists understand the tiniest technical subtleties of using cassette facades. The manufacturers of the first link, in particular, include Alga, INSI, Armax, etc. Their main advantage is the use of products from leading developers of ventilation facades as component parts. In particular, Finnish-made Ruukki cassettes (Liberta series) are widely used. This line is distinguished by both design and technical and structural advantages. The cost is also acceptable, although you should not forget about the other components of the ventilated facade. Thermal insulation and fasteners are also of great importance.