The use of fittings simplifies the layout of pipelines, regardless of their purpose. As an alternative to welding activities, this accessory is fully justified in terms of a variety of mounting configurations and in terms of reliability. Modern fittings for metal-plastic pipes are presented in a wide assortment, so it is important to carefully consider the structural parameters and tasks of this element.

What is a fitting?

This device is one of the most common representatives of plumbing fixtures. Typically, a fitting performs the task of connecting pipes or transition point devices. It is used in complex sections of bends, bends and branches, where a change in the parameters of the pipeline structure is required. But even if it is not intended to install complex units, fittings for plastic pipes can be used as a transition unit between different segments in a straight line. For example, if a large leak was detected and it is not possible to seal it with sealing devices, then you will have to embed a new segment of a similar pipe into the circuit using a fitting.

In terms of areas of application for this reinforcement there are practically no restrictions. It is used in industry, utilities and in private homes. For example, if it is planned to organize own communications for heating on the basis of a boiler boiler. In this case, metal-plastic pipes and fittings will help to realize home heating by laying heat-carrying circuits with any design, regardless of the architectural features of the premises. But, of course, before such events, a work plan should be carefully thought out, selecting the optimal mounting fittings for the characteristics.

Fittings Classifications

There are several signs of separation of this device, which allow you to select the element for specific tasks. In particular, the following classification of fittings for plastic pipes can be distinguished:

- Place of operation. Fittings for home, industrial and specialized use can be distinguished. In everyday life, small-format devices for joints and rotary assemblies are more often used, and in industry, a fitting is needed as a full-fledged transition element in a transitional technological zone. Specialized conditions for the use of this armature often require the endowment of the fitting with auxiliary functions, among which are locking and control and measuring.

- Connection method. Defines the technology for introducing the device into the pipeline circuit. Connection methods vary in a wide range - from typical mechanical and structural means to adhesive and self-fixing elements.

- The material of manufacture. Metal-plastic is a universal and practical material, therefore a wide range of different products is combined with it. Connecting fittings can be made both from metal (stainless steel, brass, cast iron), and based on plastic alloys (PVC, polypropylene, polyethylene).

Often, the part belonging to a particular classification group automatically determines its other characteristics. Household connecting fittings for metal pipes are more likely to have small dimensions and a plastic base. Unless the connection method does not depend on the place of application and other parameters - almost all connection options can be used in home plumbing.

Crimp fitting

Crimping refers to a connection method that is considered one of the simplest and at the same time reliable. In such devices, a special collet is used on the fitting, which captures the pipe by means of a union nut of the appropriate format. It is the collet that will play an important role, since the quality of filling a free cavity to ensure sealing depends on it. In crimp fittings for metal pipes, a brass ring or a split sleeve is used as a collet.

Structural designs of crimp fittings can also be different. Fundamentally different elements with a built-in fitting and threaded models. Although the concept of the crimp fitting was developed as an alternative to imperfect threaded structures, in this case a combined connection method is implemented, which has its advantages.

As for devices with an integrated fitting, they form the basis of this reinforcing group, representing an integral fixation system. In typical crimp fittings for metal-plastic pipes, the fitting can go beyond the union nut by 5-6 mm, which eliminates the risks of creases in the installation circuit.

Models with a threaded crimp also can not do without a fitting, but in this case it is plug-in. The mounting system also includes other mounting elements such as collets and crimping nuts. This type of fitting is used as terminal connectors on the output sections of radiators, collectors and other technological nodes of the pipeline.

Compression fitting

An element similar to the previous type of fitting, which has a clamping ring in the structure and is pressed with a special tool during installation. This connection mechanism can be implemented on a small segment, so it is used in conditions of dense arrangement of circuits with a large number of turns and branches. The reciprocal or additional part of compression fittings for plastic pipes is formed by a pressing sleeve and a cover in the form of a nut. In order to increase the tightness of the connection, a rubber O-ring is installed between the two groups of clamping parts .

During operation, the components of the clamping mechanism can be updated several times. At least when disassembling, it is recommended to replace the ring with another damper that is resistant to impulse shock loads. Reliability and durability of the connection will depend on the seam ring, which is used when tightening the nut. In installation activities, special equipment is involved, around the circumference clamping fittings for the press. Plastic pipes with high pressure can be deformed, so the load should be balanced and optimally suitable for a particular reinforcement.

Threaded fittings

Still used, but actively superseded by crimping devices fitting. Its advantages include simplicity and ease of installation, but due to the unsatisfactory sealing effect, threaded elements gradually leave the practice of application. But, as already mentioned, the threaded connection method can be used in combined structural solutions. The modernized fittings of this type are equipped with threaded adapters of different diameters and shapes. For example, the seal of the connected circuit in this case may be flat or conical. In combination with additional seal rings, such sealants fit tightly into the return cone of the nozzle. Modern threaded fittings for metal-plastic pipes are increasingly being manufactured according to the European standard with an external diameter of 3/4 "HP. As for the classic simplified threaded connection scheme, it is most effectively implemented only with metal (cast-iron or brass) elements, and this in itself is not the best solution for metal-plastic pipeline.

Welded fittings

It is also one of the modern variations of the structural connection of pipes, which allows joints to be made when changing diameters, in rotary nodes and branches. Direct connection is carried out by welding with thermal equipment. Particularly effective is the design of segment fittings, which can be joined with great accuracy in complex areas. The technology of electrofusion welding is also used, in which shaped structural elements are joined by embedded electric heaters. An important condition for welding segment fittings for plastic pipes is the correspondence of the internal and external diameters of the parts. Equal wall thickness will allow for a durable and reliable circuit with a nominal throughput. At the junctions of transition sections with different diameters, one can not do without using intermediate plastic reinforcement to form a bulk melt with the desired depth of adhesion.

Optimum workmanship

As already mentioned, metal is not the best option for use in a metal-plastic pipeline. It has a lot of advantages, since stainless steel and cast iron are characterized by high resistance to water hammer and durability, but the same qualities in the structure of a metal-plastic system can create increased pressure loads on weak contours. Also in the segment of plastic products, the choice is ambiguous. Experts advise to pay attention to polypropylene and polyvinyl chloride fittings for plastic pipes. Reviews emphasize their high resistance to external influences and the ability to withstand internal loads in the circuit.

It should be borne in mind that ordinary plumbing polypropylene is suitable only for cold water supply and sewage with a temperature of the medium served about +60 ° C. If it is planned to equip the heating system with fittings with temperatures up to +95 ° C, then you need to pay attention to reinforced products with heat-resistant coatings.

Constructional options

In one circuit, theoretically, a full range of fittings that differ in design can be used. When designing a pipeline, it is important to determine the connection points and transition sections with the expectation of a minimum number of joints and system optimization. A wide range of design options for fittings just helps in this:

- Adapter. A transition element for a bunch of pipes of different diameters, which may differ in the type of thread.

- Coupling. The simplest means of joining metal-plastic pipes with a fitting, which does not affect the size of the line and its direction, but only allows you to join two pieces of pipe.

- Knee. Used for vertical or horizontal drainage.

- Water socket. A water fitting used for the external outlet of a mixer or faucet. The peculiarity of this armature is that it can be used at the construction stage with subsequent wiring in the wall.

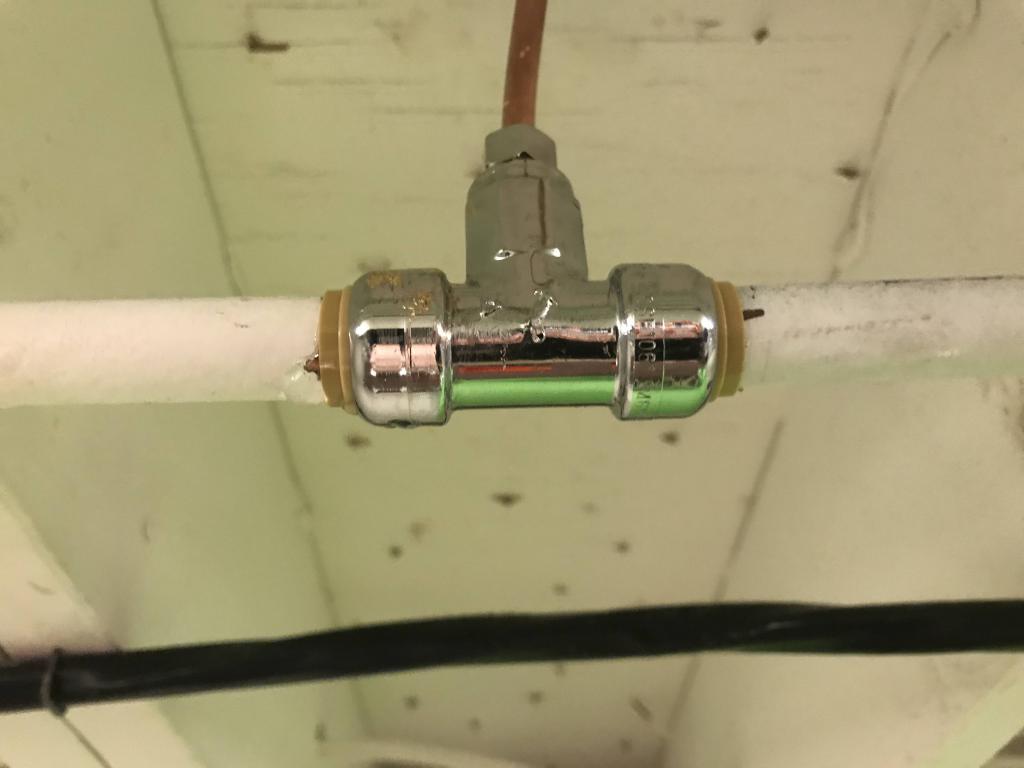

- Tee. One of the most popular fitting variations used for branching and multi-level pipe joints.

- Combined. It happens that in one device combines several design solutions. For example, a Comisa TM screw fitting for metal pipes with an external thread works according to the “collet-chuck-collet” connection system, while also being a tee adapter.

Fitting Instructions

Before assembly activities, a pipeline assembly scheme is developed, in which the points of connection, transitions and changes in the direction of the circuits are marked. Next, pipe components, fittings, tools and consumables are prepared. Burrs and dirt are removed from the ends of the connected segments. For a more reliable and tight fit, it is advisable to round the edges. Directly installation of metal-plastic pipes with fittings is performed according to the following instructions:

- A nut is mounted at the installation site, which will subsequently be tightened on the outside of the element.

- After disassembling the fitting, the clamping ring is installed so that its thicker part is oriented towards the end of the pipe.

- The pipe is inserted into the fitting until it stops, after which the clamping ring advances towards it.

- The nut is tightened. First, you must perform manual twisting, and then with the help of a pressing key to complete the operation with great effort.

This is a universal wiring diagram, which with various technical nuances can be applied to threaded and crimp fittings - again, adjusted for specific design features.

Conclusion

Each plumber seeks to minimize the presence of foreign elements in the pipeline system, while maintaining the integrity of its design. Nevertheless, there can be no question of the complete exclusion of technological units that change the line configuration in a particular section, since even simple contours cannot do without turns and, in principle, connections. To solve such problems with minimal losses in tightness and mechanical strength allow press fittings for metal-plastic pipes, which can have a variety of technical and structural designs. The key to successful assembly of the pipeline in complex areas will be the high quality of the fitting itself and compliance with the installation rules. Also, do not underestimate the value of auxiliary consumables - from rubber seals to sealants and crimping nuts.