In construction, it is often necessary to seal cracks and joints exposed to high temperature effects. Means for solving such problems must simultaneously withstand temperature fluctuations and maintain ductility. A real breakthrough in this area was the invention of a special composition, which is based on silicone rubber.

Application Features

Before applying silicate pastes, the surface must be moistened. Heat-resistant silicone should be used at temperatures ranging from +5 to + 40 °. If the temperature of the environment drops below zero, then the composition simply will not freeze. The optimum temperature for use is an indicator of + 20 °. The master should definitely use personal protective equipment in the form of gloves, since sealing silicone mixtures may contain substances that can cause chemical burns on the skin.

In order to avoid contamination of surfaces that should not be subjected to sealant application, masking tape should be used on their bases , which is glued on both sides of the seam. Experts advise strictly adhering to the instructions, which provides for compliance with the thickness of the seam, it should not be more than recommended. This is due to the fact that there is a risk of cracking during the operation of a material that may not harden.

Varieties of sealants

Heat-resistant silicone is based on polymers, which can be completely different, which gives the composition certain characteristics. Such mixtures are realized in tubes, which can have different volumes and configurations. On sale you can find two-component compounds, which, before starting work, require mixing. Quite often, they are used by professionals for the reason that stringent requirements are imposed on the composition. When mixing, you have to measure the parts, strictly following the instructions. However, the error is still acceptable, but it is only 1 g. If the ingredients are not mixed correctly, a reaction will occur, and the suitability of the silicone is only a few hours.

To solve everyday problems, it is best to use one of the varieties of silicone sealants, which is presented in a pasty form, since they are easier to apply. It is recommended to purchase high-temperature compositions for furnaces and chimneys; they are offered for sale in the form of heat-resistant, heat-resistant and

heat-resistant materials.Features of heat-resistant sealants

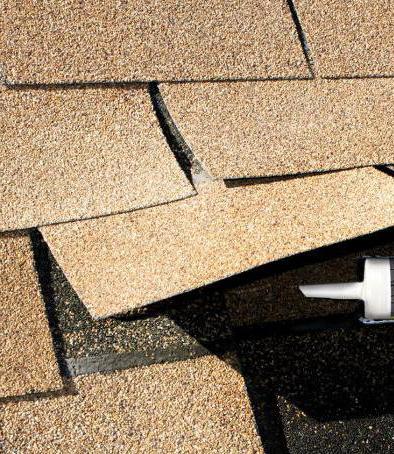

Heat-resistant silicone is one of the varieties of the described compositions and is used for places that during operation will be heated to 350 °. Their scope is the outer surfaces of fireplaces and crevices. Using heat-resistant sealant, you can close the gaps between the bricks in the masonry. However, heat-resistant sealant should not be used between furnace castings. It can be used to seal sandwich panels and roofs, as well as joints of brick chimneys.

But there are exceptions to this, which are expressed in metal chimneys. But you can close the gaps in the hot water heating system using heat-resistant sealant.

Description of heat-resistant or heat-resistant sealants

Heat-resistant silicone can be presented in heat-resistant or heat-resistant form. These compounds are able to withstand temperatures of 2500 °. If we are talking about a fireplace or stove, the scope is limited to masonry and casting, as well as furnaces and combustion chambers in boilers.

As for chimneys,

heat-resistant sealant can be used in joints and joints. This should include the place near the outlet pipe of the chimney. These mixtures can be used in areas that are in direct contact with the flame. However, before you get such a heat-resistant silicone, you should ask whether its characteristics include fire resistance and fire resistance.

Technical characteristics of heat-resistant sealant

Heat-resistant sealant is made on the basis of silicone. The temperature regime may vary depending on the composition. Thus, to increase the heat resistance , iron oxide is added to the ingredients . Such sealants cope with temperatures up to 250 °. Short-term temperature can rise up to 315 °. If iron oxide is present among the ingredients, then the paste will have a reddish-brown hue. Such mixtures are used for fireplaces or stoves made of brick.

The appearance of the surface during the sealing of cracks will not be possible to damage, since the sealant is almost invisible. It is important to pay attention to the composition of the silicone sealant, as it can be neutral or acidic. In the latter case, acetic acid will be released during hardening. Such mixtures cannot be used with metals that are unstable to corrosion.

Additional features of heat-resistant sealants

The mixtures described above are resistant to ultraviolet, so they can be used for external work, as well as for sealing the roof passage. They are waterproof and highly adhesive. The composition retains plasticity, it does not crack under vibration and deformation. The curing rate can range from several hours to several days, this characteristic will depend on the composition of the mixture.

Technical characteristics of heat-resistant sealants

Sealing silicone heat-resistant pastes are designed to fill gaps on surfaces operated at temperatures from 1200 to 1300 °. Short-term increase is possible up to 1600 °. Therefore, these sealants are often used in places where direct contact with open flame is possible. If you plan to assemble a chimney or any other design that will be collapsible, then you need to handle the joints. When loosening two links, it will be possible to crush the sealant and disconnect the parts. If you grease the glued surfaces, then the design will turn out to be almost monolithic, and disassembling it without damaging it will not work.

Heat-resistant silicone sealants have poor adhesion with smooth materials, so before applying the surface must be abrasive, then rinse and degrease again. Before sealing the surface, it is not necessary to wet, and a non-dried composition can be removed with a damp rag. Some formulations require the creation of special conditions. Thus, furnace sealants must be dried for several hours at different combustion rates. If you strictly follow the instructions, you will be able to get a tight connection or joint.

Description of KLSE silicone sealant for creating molds

On sale you can find another kind of sealant - heat-resistant silicone for molds. The resulting products can be operated at a temperature that does not exceed 400 °. If this threshold is higher, then after a while the form will lose elasticity. The described sealant is a fluid composition that has a brick color. It is implemented as a base and comes with a catalyst. Hardening occurs within 24 hours at room temperature, as a result, it is possible to obtain rubber-like products.

The surface of the original from which the mold is to be removed must be degreased, cleaned of rust and dirt, if the surface is porous, it is best to use a separating composition. The mixture should be processed the original product and left in this condition for a day or less. If the ambient temperature is lower than recommended, the curing time may increase. It will be necessary to develop a compound in half an hour.

Alternative silicone heat resistant sealants

If you are looking for heat-resistant silicone gasket, you can choose Pentelast-1110, which is used as a liquid gasket in joints and for sealing threaded pipelines. It is able to maintain performance at temperatures from -50 to + 250 °. Short-term exposure to high temperatures is also possible, but no more than 10 hours. In this case, the thermometer can rise to 300 °.

During vulcanization there are no toxic and acid emissions. If necessary, you can use heat-resistant silicone RTV 118 Q, which is colorless and is a one-component adhesive sealant. It is applied at room temperature, and in the initial state is a paste. Application can be carried out on horizontal and vertical surfaces. The operating temperature range varies from -60 to + 260 °.

Other offers

Heat-resistant sheet silicone is also popular when carrying out a certain kind of work. The dimensions of the plate can vary from 300x300 to 500x500 mm. Its thickness varies from 1 to 12 mm. This material is made of silicone and can be used in food equipment at temperatures from -50 to + 250 °. The products are safe, chemically stable, non-toxic and environmentally friendly. Heat-resistant molding silicone is used for the manufacture of gaskets. The latter can be used to seal fixed joints.

But the heat-resistant silicone spray is a universal lubricant that protects and protects metals, rubber or plastic, as well as wood. With it, you can eliminate unpleasant sounds. The material creates a waterproof protective film that does not leave greasy stains.