At the turn of the nineteenth and twentieth centuries, a new branch of scientific knowledge emerged - the psychology of management, and one of the most popular was the theory of the scientific organization of labor developed by Frederick Taylor. Taylor outlined his main ideas in the book "Principles of Scientific Management", published in 1911.

Reasons for the emergence of new management theories

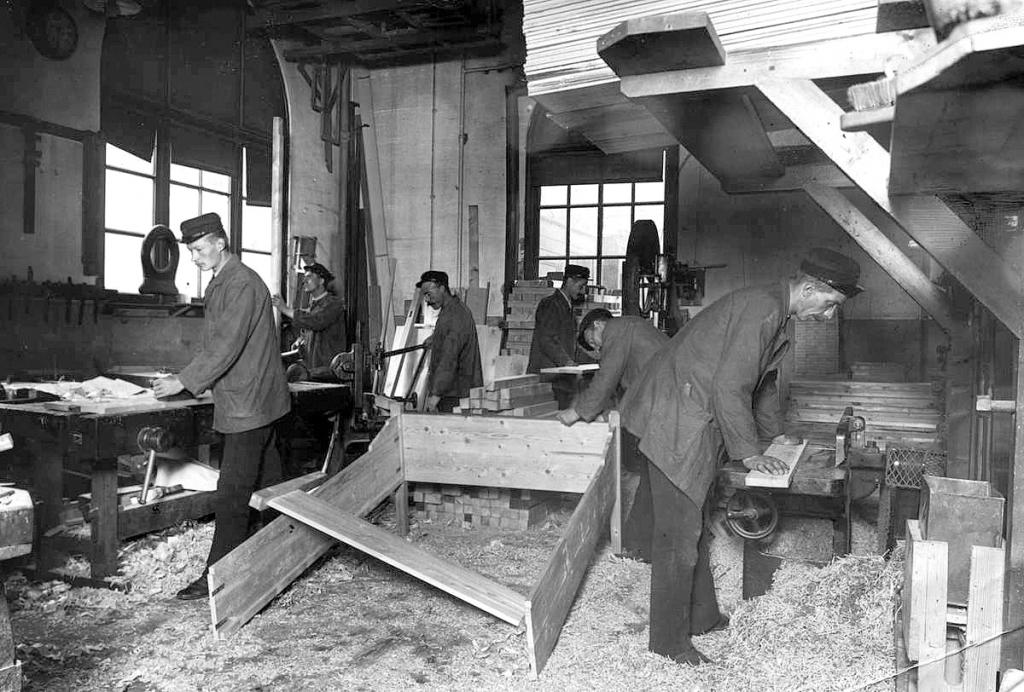

In the Middle Ages and early modern times, no special management methods were required. But as a result of the industrial revolution and technological acceleration that occurred in the 18th-19th centuries, the situation changed. Even in small factories and enterprises there were quite a lot of workers, which required the modernization of traditional management strategies.

Not only the increase in the number of workers, occurring in parallel with the complexity of the business, posed new organizational tasks. The entrepreneur is primarily interested in the amount of profit received by him. It soon became clear that inefficient management leads to significant losses. To avoid them, rationalization was required.

Organizational Management Theories

The evolution and change of technological modes is always associated with the development of science. But in this case, it is not only about inventions that drive progress. Understanding the accumulated knowledge, including in the field of management, was the basis on which new organizational models were built.

Management theories began to appear at the dawn of the last century. All of them can be classified according to two criteria: by the method of their development and subject of research. In this regard, it can be noted that some of the theories of that time were created as a generalization of accumulated experience in the field of labor organization in production, while others appeared due to the transfer of advanced ideas of economics, psychology, and sociology to a new environment.

Of particular interest is the application of the principles of the last two sciences. Almost any author of a management theory drew attention to those aspects that had not been noticed before: problems of interpersonal communication at work or employee motivation for work and its stimulation. Labor organization has ceased to be regarded as a kind of chaotic system in which feedback between workers and managers is not traced. Instead, the communications arising in production and their influence on the functioning of production itself were studied.

Frederick Taylor

An engineer by training, Taylor became a pioneer in introducing the principles of scientific management in production. He was born in 1856 in the small Pennsylvania city of Germantown in an educated family. Initially, he planned to become, like his father, a lawyer, but a sharp deterioration in his vision did not allow him to continue his studies. Since 1878, Taylor has become a laborer at the Midwhelle Steel Mill. His career goes uphill: he very soon becomes a mechanic, and then heads several mechanical workshops.

Taylor recognized the profession not only from within: in 1883 he received a diploma from the Institute of Technology. Even before the creation of his famous theory, F. Taylor became known as a specialist in the field of rationalization solutions. As soon as he got the position of chief engineer, he introduced a differential pay system at the enterprise entrusted to him and immediately registered a patent for his innovation. In total, there were about one hundred such patents in his life.

Taylor's experiments

The theory of scientific management could not have taken place if Taylor had not undertaken a series of tests of his observations. Their main goal he saw was the establishment of quantitative relations between productivity and the effort expended on this. The result of the experiments was the accumulation of empirical information necessary to develop a methodology for performing the various tasks that a worker faced in the process of labor.

One of Taylor's most famous experiments was to determine the optimal amount of iron ore or coal, which one worker can lift on shovels of various sizes without losing his ability to work for a long period of time. As a result of careful calculations and several checks of the initial data, Taylor found that, subject to such conditions, the optimal weight is 9.5 kg.

Along the way, Taylor made an important observation that the optimal weight is affected not only by the time taken to complete the task, but also by the rest period.

Taylor's Evolution

Thirty-odd years have passed from entering a steel mill as a simple worker to publishing fundamental work on control theory. Needless to say, for such a long time Taylor’s views have changed due to an increase in the volume of knowledge and observations.

Initially, Taylor believed that the introduction of the principle of piece payment was necessary to optimize production. Its essence was that the employee’s initiative should be paid directly, which could be measured in units of time: how many products a person produced, for so much he should receive money.

Soon Taylor revised this postulate. The experiments associated with determining the optimal correlation of the efforts made and the result obtained allowed the researcher to say that in the production process control is not of the greatest importance for labor productivity, but for the methods used. In this regard, he is taken to develop practical recommendations for employees, and also sets new wage boundaries: the highest for hard work and the minimum for light.

In the final phase of formulating his theory, Taylor came to grips with the scientific analysis of labor activity. The reason for this was the reflection on the formation of a certain body responsible for the planning of labor activity at the enterprise. The very idea of decentralization of management on the basis of competence required the identification of new grounds for control. These included the time spent on labor, the determination of the complexity of a particular task, and the establishment of signs of quality.

Basic principles

Based on his work experience, observations and experiments, Taylor formulated the main principles of his control theory. Taylor first of all sought to prove that scientific management is capable of producing a real revolution in production. Previous authoritarian methods based on a system of fines and other sanctions up to dismissal, according to the researcher, should have been canceled.

Briefly, the principles of Taylor's theory are as follows:

- The division of labor should occur not only at the grassroots level (that is, within the same workshop or workshop), but also encompass management layers. This requirement implied the requirement of narrow specialization: not only the worker should fulfill the function assigned to him, but also the manager.

- Functional management, that is, the implementation by the worker of the tasks assigned to him, should be carried out at each stage of production. Instead of one master, there should be several at the enterprise, each of which would give the worker recommendations according to his competence.

- Detailing of production tasks, which implied the existence of a list of requirements for a worker and practical recommendations for their implementation.

- Stimulating worker motivation. Taylor considered it necessary to convey to everyone that the remuneration of his work directly depends on productivity.

- Individualism understood in two dimensions. Firstly, it is the limitation of the impact on the work of a particular person of the crowd, and secondly, the consideration of the individual abilities of each employee.

Planning system

As can be seen from these principles, Taylor’s management theory was based on a rather strict management of the employee’s actions from the outside. This was precisely the rationalization position of the author of the theory, which later became the main object of criticism from the trade unions. Taylor suggested introducing a special department at enterprises that is responsible for rationing and optimizing production.

This body was supposed to perform four main functions. Firstly, it is the supervision of production order and the identification of priority areas of work. Secondly, the creation of production instructions that reflect the methodological principles of the implementation of the tasks. Thirdly, the rationing of the duration of the production cycle, as well as the study of its impact on the cost of marketed products. The fourth task of the planning department was to control labor discipline.

At the grassroots level, these postulates of Taylor’s theory of organization were implemented by the reorganization of managerial staff. For their implementation, according to the author, four employees were required: a foreman, an inspector, a repair foreman, and also an accountant who determines the pace of work.

Human factor

The excessive sociologization prescribed by F. Taylor’s theory of management was partly offset by her attention to an individual worker, something that management did not know before. It was not only about the developed principles of bonuses or taking into account individual abilities. Taylor's classical theory also called for the need for professional selection and training of workers.

Since there were no special skills tests yet, Taylor developed them himself. For example, a speed test was especially often used for product quality control workers.

There was a certain patriarchy at the enterprises, manifested primarily in the fact that in the spirit of the Middle Ages, young workers were trained by already experienced craftsmen. Instead, Taylor suggested developing specialized programs for training courses, as well as continuing education courses.

Criticism

The theory of F. Taylor immediately provoked protests from the trade unions, who saw in her postulates the desire to turn the worker into a "spare part" at the enterprise. Sociologists and philosophers also noted some unfavorable trends in the constructions of the American researcher. For example, the French sociologist Georges Friedman saw in Taylorism the gap between the principles of trust declared by him between managers and workers and their actual implementation. Planning and vigilant control of a person at each stage of labor did not contribute in any way to the warm-hearted relationship between workers and superiors.

Other critics, in particular A. Chiron, considered the division into thinkers and performers established by Taylor's theory unacceptable. Based on the fact that such a division was provided for by the practical part of his work, Taylor was accused of ordinary demagogy. Even stimulating the initiative of the worker caused a lot of complaints. As an example of the fallacy of this postulate, there were cases when workers, on their own initiative, limited production standards, which led to a decrease in their wages, as well as the existence of class solidarity, in the name of which people made various sacrifices, including material ones.

Finally, Taylor was accused of ignoring the capabilities of the human body. The issue in this case is not only that the rationing, no matter what experiments on timekeeping of labor were carried out, was flexible, but also about depriving the worker of the right to creative activity. Detailed recommendations led to the fact that the spiritual aspect of labor remained the monopoly of the factory bosses, while the worker himself sometimes did not suspect what he was doing and why. Sociologists drew attention to the possible dangers of both psychological and technical nature from the separation of the execution of tasks and thinking.

The meaning of Taylor's concept

Despite a number of criticisms, fairly fair in their essence, Taylor’s theory of control is undeniably important in the history of management psychology. Its positive side in the first place was the rejection of outdated methods of organizing labor, as well as the creation of specialized training courses. Taylor’s recruitment methods, as well as his fundamental requirement for regular recertifications, albeit modified to meet new requirements, continue to exist to this day.

Taylor managed to create his own school dealing with problems of scientific management. His most famous followers are spouses Frank and Lily Gilberta. In their works, they used movie cameras and microchronometers, thanks to which it was possible to create practical recommendations for increasing labor productivity by reducing the amount of effort spent. Taylor’s recruiting ideas were also common: Lily Gilbert is now considered the creator of such a discipline as HR.

Although Taylor’s school was engaged in purely improving production efficiency at the grassroots levels, leaving aside the problems of intensifying the labor of managers themselves, its activity was a turning point. The main provisions of Taylor's theory were quickly borrowed by foreign manufacturers who introduced it in their enterprises. The most important thing, perhaps, was that Taylor first raised the question of improving management methodology with his activities. Since the release of his book, this problem has been dealt with by numerous scientific trends and schools, and new approaches to the organization of labor appear to this day.