Any heating unit is a device that heats the coolant. Almost 99% of all boilers that exist on the market today have a high efficiency. The strapping of such equipment plays an important role and is responsible for how efficient the heat transfer will be, how comfortable the person in the house will feel. For this reason, there are all kinds of disputes about which strapping scheme is optimal, and also with which of them the heat transfer level will turn out to be as high as possible.

Types of tying schemes

TT boilers can be tied according to one of the existing technologies. You can talk about which strapping will be more effective or better after analyzing the design features of the heating system. If you want to learn about the simplest scheme, then you can consider the one that represents the connection of the boiler to the gravitational system. This scheme is simple, but provides a high efficiency and safety. If such a scheme is used, then an expansion tank of a membrane or open type is required. In the second case, the location of the tank plays an important role, as for the first case, the presence of a safety valve is important. Tying the TT boiler according to this scheme is very simple, but it is difficult to control. The need for constant monitoring of the amount of fuel and high consumption of resources require design improvements. You can outwit the circuit by inserting a three-way type thermal valve. In this case, a certain water temperature will be maintained by mixing the coolant with the return and supply. It is possible to use constructive solutions with pumping equipment, the use of solid fuel boilers of low power or thermocouples. The valve is mounted on the return flow of water, and when the temperature of the coolant is higher than the standard, the automation blocks access, after mixing it stops.

Alternative strapping options

Long-life TT boilers must be installed in tandem with the pump. For the reason that they work from the network, it is necessary to monitor its presence. For example, a heat accumulator will solve the problem of shutting down pumping equipment. The layout of the solid fuel boiler strapping may turn out to be different from the above, however, a number of features are generally accepted.

Strapping Tips

Not only can you make a TT-boiler with your own hands, but also make it strapping. For this, certain recommendations should be taken into account. Therefore, the connections must be made properly. The most common circuits are those that assume the presence of two circuits. The use of pipes made of combustible materials is completely unacceptable. Polypropylene strapping can only take place when certified products are used. Maintenance should be carried out regularly, this will keep the system in working condition. In order to eliminate premature damage to the pipe, it is necessary to keep the coolant in a clean state. The binding should be done correctly and correctly, only then the system will be effective. It is also important to calculate the correct boiler output. TT boilers of long burning must be cut off according to the technology, it assumes the presence of an air vent, which eliminates the possibility of airing the system. In order to prevent possible leakage on the joints, it is necessary to use paronite. If we are talking about a room that has a small area, it is best to use the natural course of water. The dimensions of the expansion tanks must be calculated. The larger the strapping, the larger the tank should be.

Additional recommendations

TT-boilers should be tied up taking into account the high-quality performance of all nodes, elements and parts, it is these parameters that determine the quality of the strapping. If you use low-quality parts, then you will waste time and money. The described process should be carried out during the off-season period, only in this way you can eliminate the room overheating.

Specialist advice on self-manufacturing solid fuel boiler

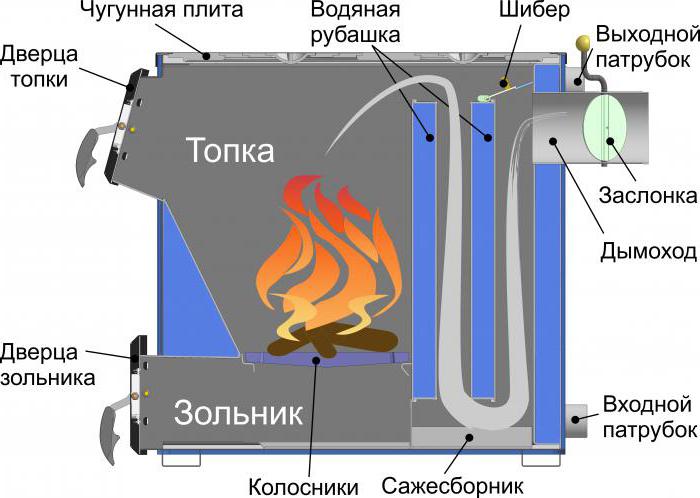

TT boilers have a fairly simple design. The heat exchanger can be made using sheet steel, giving the workpiece the appearance of a water jacket. In order to achieve maximum heat transfer efficiency or increase the area of contact with the flame, as well as the heated gas, the jacket design should have two reflectors, they are protrusions facing inward. TT boilers are often manufactured according to the principle, which involves the presence of a water jacket and a slit-like register. A water jacket is located around the combustion chamber, but as for the second element, it should be made of sheet metal and located in the upper part.

Alternative manufacturing options

You can make a boiler yourself. The energy of TT equipment will be used with greater efficiency if the work is carried out according to technology. You can use one of the proposed options. Some devices include a water jacket, which is complemented by heat transfer registers. The latter are made of pipes located in the upper part of the combustion chamber. Among other things, such units are designed for cooking. Another option for the manufacture of the boiler provides for higher power and the presence of a door, which is located on top and involves top loading.

Features of manufacturing a boiler with top burning

If you will make a TT-boiler, the scheme of this unit will help you during the work. If we are talking about equipment with upper combustion, then it will differ from the above. Considering the features, we can distinguish a shape that has a circular cross section. This indicates the possibility of using pipes of different diameters in the process of work. The second distinctive feature is the burning of fuel from top to bottom. To ensure such a combustion process, it is necessary to equip the air supply from above, while masses of oxygen will flow to the combustion site. In this case, this function is performed by an air-supplying telescopic pipe; it rises when fuel is loaded and lowers after ignition. With gradual combustion, this element will fall down under its own weight. The pipe in its lower part for a uniform supply of oxygen should have a pancake equipped with blades.

Conclusion

You must adhere to generally accepted technology if you intend to make a boiler yourself. The energy of TT equipment will be sent as efficiently as possible if an oxygen heating chamber is installed in the upper part. The supply of air masses and the burning rate will be adjusted by a valve at the entrance to this chamber. The heat exchanger in this case should be made in the form of a water jacket, which should completely encircle the combustion chamber.