The need to perform welding work under water may be due to various reasons, as a rule, associated with construction work. For example, this may relate to the installation of structures of hydroelectric stations, port groups, bridges, etc. Pipeline arrangements are also widespread. In any case, underwater welding has been used for more than a year, and the quality of the result is slightly inferior to standard techniques.

Principles of forming a welding arc under water

Various technological methods of organizing the welding process under water are used. Two methods are radically distinguished: with the formation of an artificial gas medium and with the use of equipment provided with effective insulators from water. The most reliable and productive way is considered to be a method of welding in a deep-sea chamber, containing both the welder and the working unit. A dry environment is formed that completely eliminates moisture interference. Next, welding is performed under water pressure with the connection of a barocomplex providing communication supply to the chamber.

The quality of work meets the highest requirements, but technically organizing such conditions is quite difficult and expensive. Only large enterprises working on large-scale projects can afford this. Therefore, the method of arc welding in a gas bubble formed during the evaporation of water and molten metal elements is more often used. In this process, the coating of the electrode will play an important role.

Required Equipment and Materials

Welding can be performed on alternating or direct current. Equipment with consumables is selected for specific arc parameters with the expectation of providing protection against short circuit and loss of combustion stability. By the way, the average arc voltage should be 30-35 V. The power sources are single-post and multi-post devices, complemented by the traditional combination of transformers (generators) and converters. The voltage of the units at idle should vary on average from 70 to 100 V.

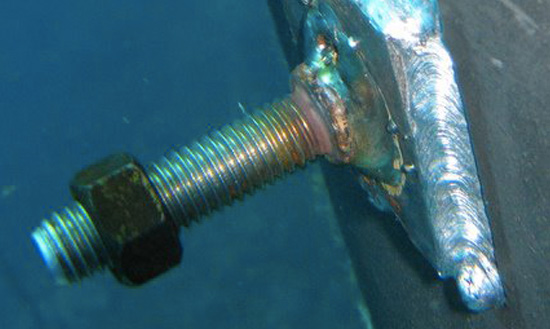

Particular attention is paid to the selection of electrodes. For underwater welding in manual mode, rods with a thickness of 4-6 mm are used. But the most important thing is the characteristics of the electrode coating. At a minimum, it should be a waterproof layer impregnated with nitro-lacquers, paraffin, solutions of celluloid in acetone and synthetic resins with dichloroethane. A diver-welder handles the electrode using a special electrode holder, provided with electrical insulation over the entire surface.

Instructions for performing hydraulic welding

Dry welding technology in which the gas environment is localized. In the working area, a camera is mounted from portable modules that allow you to organize a dry, isolated environment under water. Metal welding is performed as follows:

- An electrode wire is fed through a flexible hose into the chamber.

- At the same time, the inert gas supply begins, which will protect the welded area and the electrode coating.

- The diver-welder regulates the wire feed using a traction mechanism.

- Through current sources located on the surface, voltage is supplied to the arc.

- Using a working tool with an electrode holder, the operator starts the ignition of the arc and directly the thermal effect on the metal.

The peculiarity of this process in relation to conventional welding on land can be called the use of a wide group of instrumentation, which allow you to comprehensively take into account the pressure, moisture and temperature in the chamber.

Wet Welding Instructions

By this method, both manual and semi-automatic welding can be implemented. When assembling large structures, the lap joint technique is usually performed, and the typical thermal exposure operations allow for the angular, tee and butt joints of the metal. How to cook under water by welding with this technology? The technique is based on the ability of an electric arc to maintain combustion in an artificially created gas bubble under conditions of active cooling with water. The welder is in a special diving suit, receives equipment and necessary hoses from equipment located on the surface. Further, the process is performed according to standard arc welding technology. In semi-automatic mode, autonomous wire feed is possible, which makes the workflow continuous. However, this method is associated with many shortcomings - including poor visibility, arc tightness, obtaining a porous seam, etc.

Features of cold welding under water

This method eliminates the need for thermal effects on the metal in order to ensure the melt. The principle of action is the chemical processes that activate a special paste. These are compositions on a one-component or two-component basis, which are a highly adhesive adhesive mixture. In particular, for welding under water, plastic and waterproof pastes with metal fillers are used. After performing putty, the composition is activated, providing durable sealing of the working area. The main disadvantage of such welding is the limited use. This method is only suitable as a means of restoration of minor damage in structures and pipelines. Such mixtures are not strong enough to connect massive metal elements.

Features of performing electric arc cutting

The working process in this case is carried out under high welding current. In this case, the equipment can be used the same as in arc welding. The electrodes are preferably used with a larger diameter - about 5-7 mm and a length of up to 700 mm. Cutting is performed as the electrode moves in the working area. It is recommended to start with a hole or an edge, and then stably maintain the cutting contour until it ends. In the case of thick sheets of metal, electric arc welding under water is performed by a smooth movement from the top point to the bottom, and fast when lifting from bottom to top. The following feature is also taken into account: as the thickness of the billet increases, the productivity of the equipment will sharply decrease in terms of electrothermal effects. At the same time, the consumption of electrodes will increase significantly.

The difficulty of performing work from the position of a welder

The problems of working under water are caused by a whole range of factors. Among them, we can mention the already mentioned poor visibility, tightness of movements due to equipment and pressure, overcoming the underwater current and the lack of reliable reference points. All this affects the accuracy of the manipulation of the electrodes and the connection of equipment. The most common and characteristic defects in underwater welding include poor penetration, bursts and undercuts. The risk of typical negative factors increases, from which on the surface they are traditionally protected by flux and gas insulating media.

Conclusion

The success of the production of underwater welding will most of all depend on the quality of their technical organization. Even the choice of the method of thermal action is not so fundamental, since all methods are based to different degrees on the principle of ignition and maintenance of the electric arc. Unless underwater welding using synthetic paste-sealants has fundamental differences, although it is used in exceptional cases. But even with this method, it is important to consider the smallest organizational details. These include the quality of working equipment, the accuracy of the preparatory operations and the coherence of the actions of all members of the assembly team. It is important to emphasize that underwater welding requires the participation of a whole group of specialists in addition to the diver. Most often, working equipment remains on the surface and a significant part of the control and regulatory operations is carried out by electricians without the participation of a welder.