Polypropylene and polyethylene are materials that are quite difficult to glue. If welding is not used, the process of joining two elements will be problematic. Among other things, surfaces need preliminary initial preparation. Alternatively, polypropylene adhesive can be used.

The main types of adhesives

If you need glue for plastic, then you should know that it has two varieties: thermosetting and thermoplastic composition. The basis of the first are epoxy, thermosetting and polyester resins. The second category of adhesives can be divided into two directions, the first is made on the basis of rubbers, while the second is based on resins.

Thermoplastic compounds soften materials and dissolve under the influence of temperature. If we compare them with thermosets, they do not change their chemical structure when glued, which is a significant plus. Adhesive for polypropylene can also be divided by the number of components, such mixtures can be one- or two-component. The first are presented in finished form in one package. These include the Moment adhesive for polypropylene. And the second is packaged in two packages, each of which contains the ingredients for mixing. As an example of a one-component composition, Cosmoplast 500, which is used to connect profiles in window production, can be considered. If you need a two-component composition, then you can use epoxy adhesive for plastic, which is made on the basis of hardener and epoxy. Two-component adhesive has the advantage that is expressed in the long shelf life. The reason is that before joining the ingredients do not come into contact and hardening does not occur.

Main characteristics of Cosmoplast 500 glue

The aforementioned adhesive for polypropylene acts as a one-component composition that can be used in industry and everyday life. It can be used for bonding joints at an angle of 45 °. This mixture surpasses its analogues in a shorter drying time. The composition is resistant to water, cold and heat. The approximate drying time is 3 seconds, and the final solidification time at 20 ° C is 16 hours.

Cosmoplast 500 Instruction Manual

If you decide to use the above adhesive for polypropylene, you should first familiarize yourself with the features of its use. It is necessary to use the mixture from a measuring container or together with Cosmoplast CA, which is a measuring device. Application should be carried out on one side of the surface, which must first be cleaned of dirt and dust, and also dried. Cleaning can be done using special tools like Cosmofen 60. Surfaces must be bonded and pressurized for a period of time until dry in the open. Due to the low viscosity, the described composition may not withstand the tension of the glued gap. If there is a need to connect large gaps, Cosmoplast 564 may be used at discretion.

Glue cleaning

The adhesive for bonding polypropylene can be cleaned in a still dry form using the Cosmoplast 597 preparation. Rinsing the measuring container from dry glue is carried out using the same means. If the glue has already dried, then you can clean it manually. When surfaces contain solvent, glue that has already been dried can be completely removed.

Dow Corning 7091 Adhesive Sealant Specifications

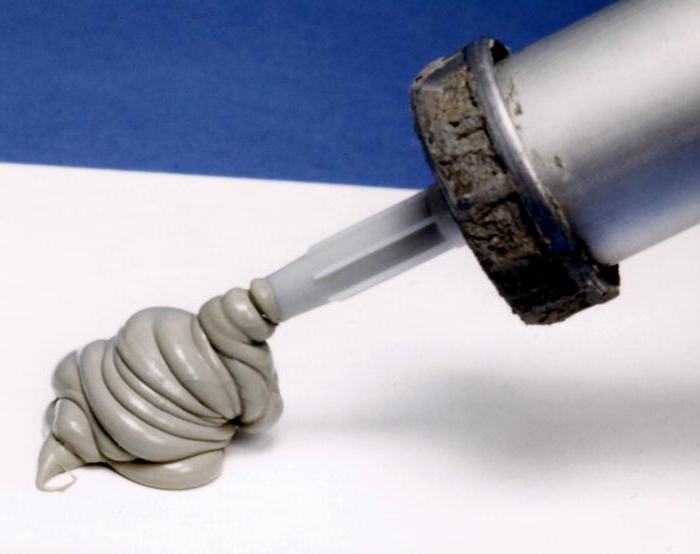

This polypropylene adhesive sealant is a viscous fluid mass that is used to seal joints and protect various surfaces. The composition can be used for bonding homogeneous materials to each other. Among the main characteristics of this glue can be distinguished such as:

- ability to seal and glue different materials;

- heat resistance;

- resistance to ultraviolet rays;

- durability;

- high adhesion with different materials;

- high elasticity of the seam.

It should be remembered that the sealant can be characterized by an acid type of curing, which indicates that the composition has the ability to release a certain amount of acetic acid during the solidification process. This can cause the destruction of non-ferrous metals and their corrosion. This should also include marble and some other materials. This glue is universal, it is convenient and easy to use, it has the qualities of water resistance and resistance to chemicals and vibration. It can be operated at temperatures from -55 to +180 ° C. This transparent adhesive for polypropylene hardens at room temperature, it has good adhesion without additional priming with conventional materials. The composition is capable of acting as an adhesive with a layer thickness of up to 5 mm; it can be used as a sealant if a layer of up to 25 mm is formed. When applied, it is a pasty, non-viscous consistency. After the curing step is completed, the consistency resembles elastic rubber. Among the qualities, the ability to seal homogeneous materials and those that have different coefficients of thermal expansion should be highlighted.

Why you should choose Dow Corning 7091 adhesive sealant

The adhesive described above for polypropylene and polyethylene has the qualities of oil resistance, resistance to moisture, high elasticity and strength. It is easy to apply, among other things, it is able to endure temperatures from -55 to +180 ° C.

Application Features

Sealing surfaces must be degreased, cleaned and dried. Degreasing is possible with solvents such as acetone or isopropyl alcohol. The required amount of sealant should be applied to one of the surfaces, and then connect the two bases. You can adjust the relative position of parts within 15 minutes after application, until a film forms on the surface of the adhesive. If the conditions of room temperature and relative humidity of 50% are met, then the vulcanization rate will be 2 m per day. If the humidity is reduced, the solidification time will increase.

Characteristics of two-component WEICON Easy-Mix PE-PP glue

This composition is a two-component mixture for bonding polypropylene and polyethylene. It is made on the basis of acrylate and has a high adhesive force of low-energy plastics and plastics. It is noteworthy that pre-treatment of the surface is not necessary. This composition is universal, so it can be used for bonding polyamide, polyvinyl chloride, polycarbonate, polymethyl methacrylate, as well as fiberglass and other materials.

Conclusion

If using one of the above compositions you plan to glue polypropylene pipes, then the temperature in the room should be in the range from +5 to +35 ° C. It is important to have a glue gun, natural bristle brushes, as well as a pipe cutter. Before applying the adhesive composition, the edges of the sections should be cleaned, only in this way it will be possible to obtain high reliability of the seam.