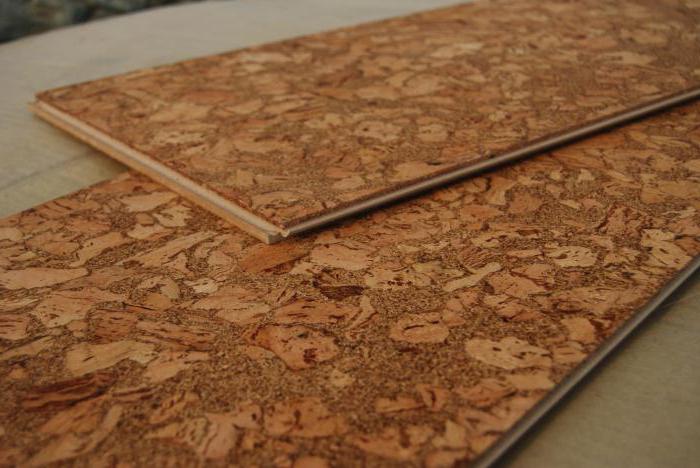

Cork flooring is quite popular among owners of apartments and country houses. And no wonder. The advantages of such a material is simply a huge amount. They make it from the bark of cork oak growing in the forests of Portugal and Spain. In the manufacture of such boards, a substance obtained from the cashew shell is used as a binder.

The main advantages of cork

This modern flooring among property owners enjoys popularity primarily due to its environmental safety. Indeed, in its production only natural materials are used. During operation, the stove does not emit absolutely no harmful substances into the air.

In addition, the advantages of cork flooring include:

- Antistatic and hypoallergenic.

- Good thermal insulation performance.

- Resistant to moisture.

- Attractive appearance.

- Good sound absorbing qualities.

Cork flooring does not absorb any unpleasant odors. And mold never appears on it. This material is distinguished by its resistance to ultraviolet radiation. Therefore, it can be fearlessly laid even in well-lit rooms. Another plus of the finish of this variety is that it is completely not afraid of vibrations. Cork coating, of course, can catch fire. However, in this case, unlike artificial synthetic materials, it does not emit any particularly harmful substances into the air.

Cork flooring: reviews of apartment owners

Since this material is simply remarkable for its performance characteristics and looks solid, the opinion of the property owners was, of course, only positive. Many people think that cork coverage looks no worse than parquet. But at the same time, it is much more resistant to mechanical damage. Cork has also earned good reviews from owners of apartments and houses because it is very pleasant to walk on it. Such a floor is never cold.

What should I look for when buying?

When choosing cork floors, you should first of all take into account such important factors:

- Variety of coverage.

- Its design.

- Brand of the manufacturer.

- The thickness of the material.

- Its design features.

What types of cork flooring are there?

This finishing material is classified into three main groups:

The first cork flooring can be safely operated for 10-40 years. There are no traces of furniture legs on it. In addition, it is resistant to chemically aggressive substances and is very easy to install. Liquid cork coating is a new finishing material, which appeared on sale recently. Putting it on the floor surface is even easier than installing the tile. The installation technology of such a cork resembles simple coloring. After drying, the liquid coating becomes porous and at the same time very dense. That is, in its operational characteristics, it is similar to ordinary tiles. Attractive appearance is also what distinguishes this cork flooring. In the interior, it looks very solid and prestigious.

The sprayed coating from the liquid differs mainly only in the method of application. His composition is almost the same. Spray the cork with a compressor and a gun (usually in two layers).

What could be the design?

Of course, the cork flooring should be chosen in such a way that it harmoniously fits into the design of the entire room as a whole. The color of the material can vary from light beige (almost white) to brown and reddish. There are also yellow and even black tiles of this variety on sale. The cork texture usually mimics wood. However, on sale there is also a finish of this variety "marbled" or in the form of sandstone. In some cases, silicone lacquer is applied to the cork. This makes floors even more resistant to abrasion and scratches.

Design Features

Liquid and sprayed types of cork coating are easy to install and look attractive. However, in our country such materials are used quite rarely. Most often, owners of apartments and houses veneer the floors with still more familiar tiles. This kind of coating, in turn, is classified into two more large groups: adhesive and castle. The first option is better suited for rooms with high traffic. Laying the cork flooring of this type, as can already be judged by the name, is done on glue. Such a tile holds on the base very tightly. Many property owners also use it for rooms with complex contours.

Castle cork floors are mounted on the same principle as the popular laminate. Each plate in this type of coating is equipped with a special lock. Unfortunately, this mount cannot be called too reliable. Such cork floors are quite quickly shaken. Therefore, floating coatings at the final stage of installation are covered with a special varnish, including cracks. The need for this procedure is primarily due to the fact that in the event of ingress of water between tiles, the service life of the entire cork floor is significantly reduced.

Manufacturer's Tips

In building hypermarkets, cork flooring is currently sold by a wide variety of companies. These can be Egger, Corkart, Allied Cork, Wicanders, etc. Specialty stores mainly sell European cork brands. The Chinese, fortunately, have not yet mastered this market. And therefore, any cork today can be bought almost fearlessly.

Prices

Most often in building hypermarkets there is material of this variety of the Portuguese company Wicanders. This is perhaps the best cork flooring today. A square meter of plates from this manufacturer with a thickness of 4 mm will cost about 1000-1500 p. For the same material, but at 6 mm, you will have to pay 2,000-3,000 rubles. Tile thickness of 11 mm is even more expensive - about 4000 p.

Features of mounting adhesive tiles

The thickness of such a coating can vary from 3 to 6 mm. It is a pressed cork coated with veneer of the same material and additionally treated with a protective compound. In order to perform high-quality installation of such tiles, you should first take care of buying a suitable glue. Cork wood flooring is a material that, as you might have noticed, is quite expensive. And therefore, glue should not be saved for him. To purchase is a tool recommended by the manufacturer. The exception is only those cases when the coating is mounted in a pool or bathroom. For such rooms it is worth buying a special moisture-resistant glue.

Carrying out the actual installation itself, you must strictly follow the manufacturer's recommendations. Instructions should be followed exactly. The fact is that warranty obligations for cork coverings apply only with strict observance of the laid laying technology.

Preparatory work

Before you start installing the tiles, the floors must be leveled. The concrete base should be adjusted using a self-leveling mixture. On a wooden surface you need to putty all chips and scratches. If on such a floor there are hollows-scuffs or any bulges, it should also be pre-cycled and sanded.

What tools will be needed?

To work with cork, you should prepare a meter rule, a construction square and an office knife. You also need to purchase a wide glue tray and a new paint roller. For even laying, you need a chop thread. In addition, you should purchase a special rubber mallet for parquet. Glues of different composition can be used for laying tiles. Some of them have no smell. Others emit very harsh and unpleasant aromas. In the latter case, before starting work, wear a respirator.

Adhesive Installation Tips

Start work on laying the cork should be from the center of the room, moving to its edges. In order for the coating to lie as evenly as possible, a preliminary breakdown should be done with a thread. In the process of laying, glue is applied both to the tile itself and to the floor. It should be spread evenly over the cork. Such adhesives dry quite quickly. Therefore, experts recommend simultaneously applying the product to as many tiles as can be laid in no more than half an hour. Accordingly, the surface of the floor should not be smeared entirely, but partially.

Cork boards must be laid as tightly as possible to each other. Do the work more carefully. Correcting something after some time after installation due to the quick drying of the glue will not succeed. Mount the tile so that the seams are jogged. In order for the elements to lie tightly and to the surface, it is necessary to tap on them with a mallet (over the entire area).

When laying the adhesive cork floor, the rule should be used to control the evenness of the rows. This tool is applied to the end of the tiles and see that there are no swelling and waves on the finished surface. Like parquet, cork flooring with fluctuations in humidity and temperature can slightly change its area. Therefore, it should be laid in such a way that around the entire perimeter of the room between it and the walls there is a gap of about 5 mm.

Sometimes it happens that with the edge of the room at the final stage of laying the whole tile does not fit. In this case, you should measure the distance from the wall to the last row laid and transfer it to the material. Tile must be carefully cut - with a sharp clerical knife. Having made a deep incision, the element is carefully broken by hands.

Features of laying lock plugs

If the cork adhesive flooring is installed in approximately the same way as parquet, the floating floor is laid in approximately the same technology as the laminate. Previously, such a tile should be maintained in the room in which it will subsequently be laid, within 24 hours. Installation in this case is made from the wall. When laying a floating coating, as well as during the installation of the adhesive, temperature gaps should be left around the perimeter of the room. The floor is tiled with this type of tile in the following order:

- The first row is laid. When assembling it, the spikes on the ends of the panels should be firmly inserted into the grooves of the previous elements.

- The last panel is cut to the required length. Its remainder is used as the first element in the next row. This ensures the expansion of the seams.

The side panel is attached to the element of the previous row, inserting it with a spike into the groove at an angle of 45 degrees. After the coating is fully assembled, it is advisable to additionally treat it with varnish recommended by the manufacturer, or seal the joints with sealant.

If in most cases the installation of adhesive tiles is trusted by specialists, then the cork flooring with a lock, as you can see, is easy to assemble with your own hands. The cladding technology in this case is extremely simple.

Coating Care Features

Contact with various kinds of chemicals the cork transfers relatively calmly. Therefore, the floors lined with it can be washed using any household cleaning products. The only exceptions are those cases when stubborn spots appear on the cork. It is not worth rubbing such contaminants with shampoo. It is better to use a special tool designed for cork. Like parquet, it is advisable to periodically rub the coating of this variety with a special compound prepared on the basis of paraffin and wax. The use of such a tool will help to make floors more attractive and at the same time significantly extend their service life.