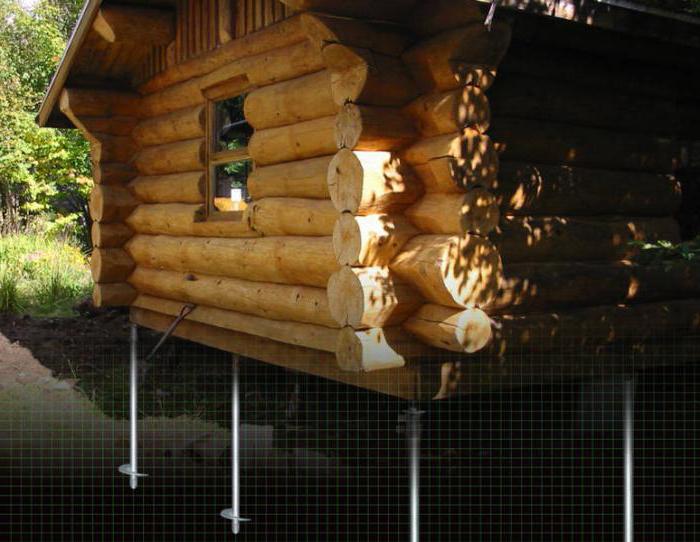

Today, screw piles are increasingly used for the construction of the fundamental foundations of private houses and for the construction of larger industrial facilities. Supports of this type experience enormous loads and, after the construction is completed, continue to be subjected to the destructive effects of environmental factors. That is why many are now interested in whether it makes sense to use screw piles or is the service life of these widely available building elements too short?

A bit of history

Screw-type piles appeared about 200 years ago. All this time they were widely used in the construction of bridges, moorings, towers, power lines and many other serious facilities. There is a lot of evidence that the life of screw piles can reach up to 150 years. For example, the pier, which has been standing in sea water on similar supports for more than a century and a half, has still not collapsed.

There are entire museums where visitors can personally see the tips of the very first screw piles. However, all this does not mean that metal structures will last forever. Negative reviews on the service life of screw piles are quite justified, since the supports made by the artisanal method really collapse quite quickly. The manufacturing technology of building structures differs in a lot of nuances and features. If the production standards were violated, then the finished piles will not last even a third of the declared time. Therefore, it is very important to pay attention to these subtleties when choosing structures for the foundation.

GOST service life

According to state regulations, the service life of screw piles is from 60 to 120 years. GOST also indicates the following data:

- Electromechanical corrosion of metal in the soil develops at a rate of 0.02 to 0.05 mm per year.

- The wall thickness of the screw and the support itself is at least 5-6 mm.

- The pipe walls decay at a speed of 5 mm / 0.5 = 100 years.

In addition, piles are covered with special polymer compositions of a two-component type, which retain their properties for 7-15 years. This allows you to increase the service life of screw piles under the foundation. If during the manufacture of the supports these conditions were violated, the products will be less reliable and durable.

Is there a difference between cast screw and weld piles

There are no significant differences between such products. Cast tips are made of standard steel marked 35L. The main difference between these support elements is that helical lines are not welded to the pile cones, but are immediately cast along with them. However, few people know that in fact cast tips are welded to the pipe. This means that when using them, it will not be possible to avoid welds.

If we talk about the shortcomings of cast tips, then in their production it is necessary to control the level of quality of the pour. In addition, their manufacture is impossible without the use of ultrasonic equipment. The fact is that in the material from which the product is made, small cracks, pores and voids can occur, which will significantly reduce the strength characteristics and service life of screw piles.

Welded tips can be checked independently, since even with a visual inspection it becomes possible to assess the quality of production. Cast piles cost almost 25% less.

Is there a difference between painted and galvanized pile tips

The main difference is resistance to corrosion. According to numerous reviews, the service life of screw piles treated with paintwork material is significantly lower due to the influence of an aggressive environment. The protective coating lasts a maximum of 15 years, after which the metal products begin to quickly become covered with rust.

Piles that have undergone hot dip galvanizing do not corrode for 40-50 years. However, it all depends on the aggressiveness of the soil. Thanks to the hot dip galvanizing method , a layer of 0.2 mm thickness is formed on the surface of the piles, which does not wear out over a long period of time. In addition, the protective layer of zinc will not be rubbed off while screwing the support.

It is also worth paying attention to the cost of products. Supports that have undergone hot-dip galvanizing will cost 25% more than products treated with paints and varnishes.

What affects the decrease in durability

The service life of the foundation on screw piles can be significantly reduced due to the following factors:

- The impact of mobile soils. Under normal conditions, soil has a minimal effect on screw piles. However, when it comes to extreme conditions and increased mobility of the soil, this may affect the operational characteristics of the supports.

- Thermal impact. Due to seasonal temperature fluctuations, the metal is constantly narrowing and expanding, its structure is broken. The bearing capacity of the supports is significantly reduced, as cracks and pores appear in the material. When using high-quality piles, the number of freezing and thawing cycles of which is enough for up to 120 years, this does not happen.

- Chemical corrosion. If the level of acidity is exceeded in the soil, then the rust on the piles will spread much faster.

- Electromechanical corrosion. Such damage occurs during strong oxidation of piles due to stray currents, which may be part of the soil. Most often, electromechanical corrosion affects supports located near underground cables or various industrial facilities.

How to increase the life of screw piles

There are several ways that will help extend the “life” of the foundation installed on supports of this type:

- Use piles with thickened walls. Each millimeter of metal extends its service life by approximately 15 years.

- Use supports made of alloy steel only. Piles should be treated with special compounds that prevent chemical corrosion.

- If the products are not protected from rust, you must independently coat them with anti-corrosion compounds.

- Concreting the inner trunk. Thanks to this procedure, it is possible to protect the structure from moisture and increase the bearing capacity of the support.

During the installation of piles, it is not recommended to use impact equipment. This will save the structure of the products and increase their life. If the installation of piles was carried out in accordance with the regulations, then the supports will last up to 100 years.

Benefits of Screw Piles

Despite the problems that may arise during the operation of supports of this type, they are still very often used for the construction of foundations and the construction of other structures. This is due to the following advantages of screw piles:

- A medium-sized base can be built in the shortest possible time (no more than 1-2 days).

- The cost of the foundation is almost halved, making the construction of the entire structure much cheaper.

- Screw piles are optimally suited for use on unstable soils.

To summarize

Knowing the truth about the life of screw piles, you can build a durable, reliable and strong foundation in a short time. The main condition is compliance with the technological process of manufacturing supports and proper installation of products.