Previously inherent only to the Canadian population, and now to the whole world, houses made of sandwich panels are now very popular among Russian residents. Small-sized dwellings of this type are being built in the suburbs, in the regions of the country, in the southern regions and in the most remote, northern ones. Building a house from sandwich panels is easy, simple, fast, and most importantly - not so expensive. Therefore, below we will take a closer look at the process of erecting such a dwelling, and also look at materials that, thanks to their excellent quality, give us the opportunity to live in warmth and comfort all year round.

Brief description of the material

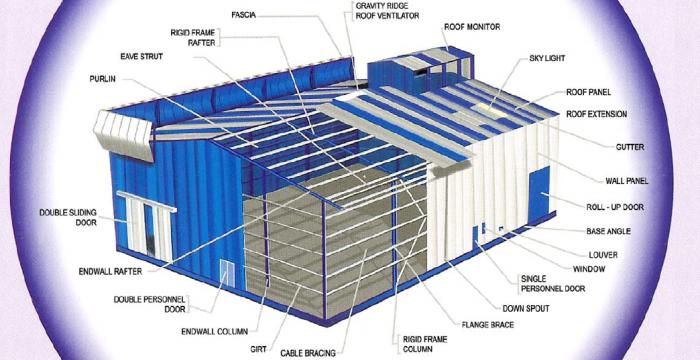

The sandwich panel itself consists of three parts. These are two dense layers (particleboard, MDF or something else) and a soft layer of insulation, which is located between them. Each layer is attached to the other by means of a hot press, so they will not be able to disconnect in the future. The very construction of houses from sandwich panels suggests that two types of such material are needed. The first is referred to as wall. Its surface is either completely smooth or profiled on one side, which gives the walls a certain decor. Roof panels are used to equip roofs . They can be profiled on both sides, or only with one - external.

Material application

Nowadays, many construction companies offer the population in the shortest possible time to build a house of sandwich panels. Reviews of people on this account, as a rule, depend on the company that took up the job, and on the quality of execution. The material itself, which is used in this process, is undeniably good in both quality and price. Domestic construction firms erect such projects in about two to three weeks. The most difficult stage in this work is the arrangement of the foundation. Further construction of walls and ceilings is as easy as shelling pears. Such houses can be sold on a turnkey basis, which is most often observed in our country. Less often, people order frame housing for themselves on an individual project. Externally, houses made of sandwich panels look like full-fledged brick cottages, mansions, with a chic appearance and impressive facades. However, not at all chic - the main criterion for such housing. According to your sketches, the workers will be able to build a medieval castle from such panels, as well as a hut with one window.

Design

Before starting work, you should definitely draw up an accurate drawing of your future home. If such work is beyond your power, then sketch a sketch, and a professional will do the calculations, with whom you will clarify all the details. It should be noted that there are also ready-made house designs from sandwich panels, for which prices have already been set in advance. Also, those buildings that are made according to standard drawings, the most economical in terms of consumption of building material. Therefore, if you first want to save money - take a note of this. The project itself, which you will compose as a result, will consist of two parts, which we consider in detail below.

Drawings of parts and products for further installation

Here we include an explanatory note with all the transcripts that will be present on subsequent pages. Then we put all the data on the floor panels, the same thing needs to be written about the wall panels of the first floor and the attic. We note the parameters of the details of wall panels. The next item is data on roofing materials. As a rule, houses made of sandwich panels are always complemented by wooden elements. It can be racks on the porch, balcony, in the house itself, etc., because in this section we also indicate all the data on them.

Assembly drawings for further assembly

As soon as you have calculated all the data for the house from the sandwich panels, we collect the project into one whole. To do this, you need accurate pictures on which the scale will be displayed and each line in accuracy. We list what we need specifically:

- ground floor plan;

- attic plan;

- sketches of facades (in axial directions);

- foundation plan and calculation ;

- foundation cut;

- a plan for mounting panels that will overlap the foundation;

- plan for mounting wall panels on the ground floor;

- floor plan for installation of floors that relate to the first floor;

- mounting plan for wall and floor panels of the second floor (or attic);

- installation of roofing panels;

- incision in the area of the stairs;

- an incision in the ridge;

- plan and calculation of the roof.

Stages of construction. Foundation and initial work

The construction of houses from sandwich panels begins, like any other, from the foundation. In this case, the requirements for it are not so high due to the fact that the walls and floors of the future home are light and unpretentious. Depth depends strictly on the terrain and type of soil. Ideally in this embodiment, a strip foundation or columnar is suitable. At the same time, workers are beginning to make an assembly system for the home. Its essence lies in the fact that a solid beam is attached to the foundation with the help of anchor bolts. This material is impregnated with antiseptics and other protective mixtures, which allows you to keep the house always clean, dry and comfortable in the future. It is on this strapping beam that panels will later be mounted.

Installation and installation of walls and ceilings

First, let's take a look at how unfinished houses from sandwich panels look. Photos clearly show us that although they are considered “cardboard huts”, they still have their own frame. It consists of boards, which are the connecting element that runs between each panel. It is on such a "lattice" that the panels themselves are attached, and all the cracks are blown with foam. Assembly of the finished house always starts from the corner. In order to mount such a dwelling, no more than two workers are required at the site. Ceilings at home always include blowing, which provides natural ventilation. Due to the fact that the house is based on a timber frame, it is easy to mount window panels and door panels.

Roof installation

At the very end, the roof of the house is mounted. The process itself is no different from the standard that was used by our ancestors. The bottom line is only that sandwich panels are nailed onto skates and floors from the timber. Sometimes the roof is also equipped with a waterproofing film for added protection (especially if you have an attic floor). After the work is completed with the main material, decorative is mounted. Its role is most often played by standard shingles. The main thing here is that it should suit your project in color and texture.

Your home from sandwich panels. Owner reviews

Everyone in our time who has acquired this type of housing has never complained about it. People say that the house is always warm, cozy, comfortable. It is made of environmentally friendly, high-quality and durable material. Another huge plus - the cost of finished housing does not exceed $ 30-33 per square meter. An important place here is also occupied by communications and equipment. All pipes, wires and other details, without which a comfortable existence in our world is impossible, in such dwellings are hidden either in special boxes or behind false walls. Well, of course, every consumer is happy with the free space that allows you to install any furniture in the house. The height of the ceilings is 2.8 m on average, and you can determine the meter of rooms for yourself.