Japanese water stones differ from domestic and western counterparts. First of all, this refers to their softness. It is determined using volumes of ligaments and pores, as well as abrasive grains.

General information

Artificial hard abrasives from North America or Europe are most often oriented towards mechanical equipment and industrial production. They are used with continuous cooling or dry. High labor productivity is the result of automation of grinding and grinding processes. This also applies to the average quality of the processed surface, as it is replete with burns and microcracks.

Manual tool sharpening: features

In this case, the hard abrasive quickly clogs due to chips. Thus, its salting occurs. Due to this factor, such tool sharpening is carried out at a fairly low speed. In accordance with European traditions, the elimination of defects occurs at the final stage by the electric method or with the help of polishing layers.

Sharpening on Japanese water stones

These sanding stones are well suited to manual work. They are used exclusively with water. The appliances are very soft and grind faster. At the same time, new grains of abrasive are gradually exposed. At the same time, a suspension forms on the surface of the bar. This occurs as a result of the interaction of spent grains with a liquid. It is known that Japanese water stones wear out much faster. However, they are able to provide high stable performance. In this case, there must be a high surface finish.

Major differences

When using small grains, a relatively quick fine-tuning of the cutting edge to excellent condition is ensured. Polished layers, felt circles, straightening slings and other traditional western accessories are not used. Water stones for sharpening knives are characterized by high performance. However, it is inferior in removal rate to diamond elements. But they, in turn, differ in a more limited range of grain size. In addition, the final stages of sharpening should be highlighted. In this case, it is very easy to overdo it and thin the blade excessively.

Marking

It is based on the granularity possessed by water stones for sharpening knives. Marking characterizes the number of holes per square inch of the sieve on which the grain fraction settles in accordance with a certain interval. Abrasive can be obtained by sieving. At the same time, the average grain size is at least 50 microns. Smaller abrasives are sieved using other methods. In this case, we mean the air separation and hydraulic method.

Determination of the number of grinding elements

It all depends on the task assigned to the grinder. Fine-grained Japanese water stones (# 6000) are suitable for dressing and refinement. For conducting a slight sharpening, other elements will be required. The knife is pre-set on a bar that has a grain size of up to # 5000. For ordinary sharpening, other parameters are characteristic - # 600-2000. The blade can be severely worn, have nicks or other damage. In this case, coarse grinding stones are used to remove defects.

Maximum sharpness

It can also be called shaving. This requires the highest individual skills in the field of fine-tuning and sharpening. However, such sharpness is not required on every blade and not always. Trying to put her on a soft stainless steel is a futile undertaking. The fact is that in this case the effect is extremely short-lived. Soft knives, which are made of low carbon steels, can be fixed using musat. It is worth noting that this will not be enough for a high-quality solid product. Thus, when buying a good knife on sharpening tools, it is impractical to save.

Replace Items

This should be done more often. To confirm, you can resort to a simple calculation. Thanks to it the abrasive and time are saved. If the granularity is gradually and gradually reduced, the traces of the previous, larger stone will be eliminated quite quickly. Thus, a good surface finish is ensured, and the longevity of the bar and its resource are also increased. A set, which includes from 5 to 7 stones, will cost not at all cheap. However, blades are rarely brought to a state where a full arsenal is required to fix them. In order to maintain the product in good shape, as a rule, only 2-3 fine-grained bars are sufficient. One polisher will also be required.

Household use

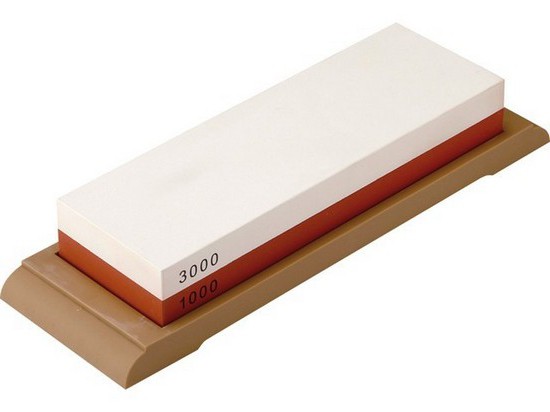

Currently, the most popular combined Japanese whetstones, which are sold at an affordable price. They consist of two halves of different grain sizes bonded with waterproof glue.

Work principles

Each water stone for sharpening must be pre-soaked. The use of deep plastic containers is recommended. It’s better to be transparent. It will be good if a separate container is provided for each type of stone. Due to this, particles of large abrasive will not fall into small. To determine the soaking time, you need to pay attention to the air bubbles that the stone makes water grinding. Porous and large elements in the process of absorption of the liquid release them for about 5 minutes. Small, with medium grit, to saturate takes more time - up to 15 minutes. Fine-grained, dense Japanese water stones are soaked for the longest. Their saturation time can be up to 20 minutes. After that, you need to install the stone on the stand. The main requirements for it are ensuring a stable position of the bar and eliminating its movement during operation. It is worth remembering that both hands are required for sharpening. Fine-grained elements suggest the creation of a layer of suspension immediately before dressing. It is advisable to use a bar Nagura.

Handling a heavily blunt and damaged blade

Coarse abrasive required - # 80-400. First of all, you should start by removing nicks. For this, the remnants of the blade are removed. Material must be removed along its entire length. Thus, the geometry of the blade will not be distorted. Do this until the damage is completely repaired. A straight line appears. Further, an assessment of the uniformity of its thickness is required. She can swim. In this case, it is necessary to restore the profile of the blade. The work is carried out with descents. Excess material should be removed. After this work is completed, the width of the face should be constant along the entire length of the blade. The thickness is selected according to the purpose of the knife. Next comes the pre-sharpening line. In this way, descent sites that are still in need of correction will be identified.

Practical recommendations

The amount of suspension increases during polishing and grinding. It must not be allowed to become too thick. Her flushing is also not required. The Japanese produce periodic wetting of the suspension. To do this, the fingertips are dipped in water, and the latter is shaken off on a bar. You can also use a disposable syringe or household spray. It is important by chance not to allow its complete washing off.

The use of the entire area of the bar is recommended. When working with coarse-grained abrasive during intensive metal removal, wear should be carefully monitored. Basically, the middle part of the bar is most at risk. Thus, the working plane is distorted, and the cutting edge collapses. There are many ways to deal with this phenomenon. The Japanese make special stones for this. Their basis is hard wear-resistant grades of abrasive. Such stones have a number of parallel cuts. They are also involved in the process of leveling the worn stone. Recovery should be carried out with water. Then wash the abrasive thoroughly. To do this, use a brush that is designed to remove stuck particles.

Storage

Bars should be kept in individual containers. It can be either cardboard or plastic. It is acceptable to store medium and coarse stones in water if they are used regularly - about once a week. Bars that are used less often must be thoroughly dried after work. Do not leave wet whet in the cold. Frozen water can contribute to its destruction. Regular editing will benefit the bar. This process simplifies maintenance and also reduces uneven wear. Chipped edges of the stone can be prevented. To do this, periodically during operation (in accordance with wear) a narrow chamfer should be placed on its face. The required angle is 45 degrees. Thin grinding water stone is recommended to stick on an even piece of wood or organic glass. This is done with waterproof glue. Thus, the service life of the bar will be extended.