Individual residential construction is not without costs, efforts and calculations, which not everyone can cope with. After all, it is not enough to build a wall of foam concrete, it is necessary to understand the details of the design, the rules of calculation and the features of the work process. Therefore, it is so important to try to understand how to build a house on your own, where to start and how to calculate the thickness of the walls of foam concrete according to the standard.

Material Specifications

Before you understand and calculate what should be the thickness of the walls of the foam blocks, familiarize yourself with the distinguishing features of the material:

- High compressive strength - from 3.5 to 5 MPa. This confirms that it is possible to build two- and even three-story houses from foam blocks.

- The material weighs a little, but at the same time it has a low density, up to 3 times lower than that of expanded clay.

- The foam block is often compared with wood due to thermal conductivity, which, in comparison with ceramic brick products, is an invaluable advantage. A wall of clay blocks with a width of 600 mm retains heat in the same way as foam concrete with a thickness of 200 mm.

- When building a house from foam blocks, there is no need to arrange additional sound insulation. Well-laid blocks protect against noise.

- The price of the material does not compare with anything. Foam blocks are cheaper than other raw materials, even taking into account transportation costs.

- Accessibility is proved by the ability to work with the material without special training. This means that you can build a house with your own hands, without additional help.

- Density.

- Dimensions of blocks.

- The way to fix the blocks.

Important! Do not forget that too cheap foam blocks do not differ in quality. In this case, the material may be manufactured in violation of the technology, and poor-quality second-class blocks may prove unsafe in construction - the structure may simply collapse. Therefore, save wisely!

Wall thickness and how to determine it

On the Internet, there is a lot of false information about how to determine which wall thickness of foam blocks is optimal. To protect yourself and find the right solution, take into account several features and build on this information:

- Determine the lowest temperature in the region for the winter season. In areas with unstable weather conditions, severe frost and wind, it is required to erect additional heat-insulated thickened walls.

- Choose a heater and determine for yourself whether you will install it or stay on ordinary plaster. For walls up to 300 mm thick, additional insulation with a material thickness of up to 100 mm is required.

- Insulation not only helps to keep warm inside the house. It also repels adverse ultraviolet radiation from foam blocks, preventing it from affecting the structure of the material.

Note! The choice of foam blocks is also affected by density. This is the first parameter that you should pay attention to. It differs depending on the technical specifications. The higher the density, the greater the cost of the products.

How to determine the thickness of the walls of foam blocks

From the foregoing, we can conclude that the recommended wall thickness of foam blocks for a house in a region with moderate winter temperatures is 300 mm with a density of D600 foam blocks and a layer of thermal insulation.

These are the optimal indicators of the thickness of the material for all regions of Russia. Due to the additional thermal insulation of the walls outside the house, the cold does not enter the room at all, which creates a favorable atmosphere even in harsh climates.

As for strength, it is noted that the load on the walls, regardless of the number of storeys, should not exceed 20 tons (together with the roof, floor slabs, furniture). According to technical indicators, it is known that every 100 mm of foam concrete can withstand a load of up to 10 tons.

Important! Do not forget to pay attention to such technical characteristics as strength and resistance to physical impact. It is easy to break through a wall with a sledgehammer at 300 mm, but 400 mm is more reliable, and the blocks themselves are distinguished by density and strength indicators.

The optimal wall thickness of the foam blocks can be calculated visually by reading the indicators in the form of a visual diagram or drawing.

Calculation of thermal conductivity and determination of the optimal thickness, based on the formula

The thickness of the foam blocks for the external walls is selected, not forgetting that the external heat transfer resistance, taking into account all layers of the finish, should be at least 3.5 ° C per m 2 / W. To determine the optimal wall thickness, consider the process in more detail, based on different indicators of block density.

According to the technical characteristic, it is known that products with the D600 and D800 indicators differ in coefficients of 0.14 and 0.21 deg * m 2 / W, respectively.

As the exterior finish, facing brick with an indicator of 0.56 deg * m 2 / W and decorative plaster with a value of 0.58 deg * m 2 / W are used.

Where to start the calculation

When calculating the wall thickness of foam blocks, follow the instructions:

- First, determine the thickness of the brickwork and the layer of plaster. Often, if the installation of a heat-insulating layer is not provided, then the brick is laid in two rows. It turns out 120 mm.

- This number is converted into meters and divided by the coefficient of thermal conductivity of the facing material. The result is a resistance equal to 0.21.

- The same is done with a applied layer of plaster, having a final value of 0.03 mm.

Work with formulas and some calculations

Then they start working with formulas:

foam concrete D600 = (3.5 - 0.21 - 0.03) x 0.14 = 456 mm,

where 3,5 is a number expressed as the total heat transfer resistance; 0.21 - brick resistance; 0,03 - plaster resistance; 0.14 - the coefficient of the foam block.

The result is a rounded number of about 450 mm (do not forget to translate the indicators from meters). This is the optimal wall thickness using the materials described above during the construction process.

Foam concrete D800 = (3.5 - 0.21 - 0.03) x 0.21 = 684 mm,

where 3,5 is the total heat transfer resistance; 0.21 - brick resistance; 0,03 - plaster resistance; 0.14 - the coefficient of foam blocks.

Now it becomes clear how thick the wall of foam blocks should be. The option of building a wall according to the second example is notable for its power. Notice that the thicker the wall, the greater the cost. Although, if you add here a typical insulation for the facade (expanded polystyrene), then the thickness of the facade will significantly decrease.

Important! The optimal wall thickness of the cinder block is calculated in an elementary way. Only in this case there is one but! Do not forget to take into account the thickness of the moisture-proof material, since without it the cinder block loses its strength.

If you plan a bath of foam blocks, the wall thickness in areas with extremely low temperatures, to -30 ° C, does not fall below 700-800 mm.

The course of the construction process: the construction of walls

According to the instructions for building external walls, you can build a house regardless of the environmental factors affecting the material. We’ll talk about some of the recommendations below.

Some rules for building a house of foam concrete

Follow the simple rules of individual residential construction, and building a house will not be a problem for you:

- First prepare the foundation. Cleaned of dust and dirt, leveled in the presence of irregularities.

- Then they proceed to calculate the required amount of materials, building blocks and adhesive concrete mortar. In 1 m 3 - 30 blocks (20x30x60 cm). When using a material with such dimensions, the wall thickness of the foam block is 30 cm.

- An approximate calculation of the glue is determined. On 1 m 3 of the wall 30 kg are left. Therefore, it is first worth knowing the total area of the vertical surfaces of the future structure.

- Having bought the materials and having collected the necessary tools, begin to knead the mortar for masonry foam blocks, of course, if you have not purchased ready-made concrete.

- First, the concrete mortar is applied to the surface of the foam block, which is placed on the tile floor or foundation.

- Before laying the next block, an adhesive mixture is applied to the end part of the first product, carefully coating the surface. Concrete mortar should fill all the hollow gaps.

- Excess glue is removed by tapping on top of the block with a mallet.

- The second row is laid out so that the joints of the blocks do not coincide, but are shifted to the side when laying each of the rows of the wall. To do this, cut one block in half and start with a half.

- Foam concrete blocks are easy to process, so you can easily fit the opening under the window or door structure.

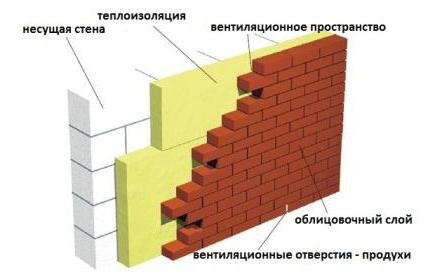

Features of facade insulation taking into account the thickness of the walls

At the final stage, the facade of the house is insulated from foam blocks. What wall thickness of the structure is determined at the design stage:

- using dish-shaped nails, install special polystyrene heat-insulating plates;

- for brickwork in a foam concrete wall, between the blocks, several rods of thin reinforcement are fixed to connect the inner wall with brickwork from the side of the building facade;

- if it is planned to finish by plastering the walls, then a reinforced mark is pulled over the foam blocks for better adhesion of the main surface and the finishing material. The plaster is applied in two layers: the first is heat-insulating, hiding the mesh, the second is finishing, finishing.

Note! The type of material used and its quantity will be better determined at the design stage to avoid unnecessary costs. Do not forget to take into account all the points: the presence of door and window openings, internal partitions.

To summarize

As you have already noticed, there are few factors affecting the thickness of the walls made of foam blocks and the definition of this parameter. Basically it is weather conditions, the presence of a second (third) floor, attic.

One way or another, you should focus on financial opportunities. It is not difficult to understand that the greater the thickness of the walls of foam concrete, the greater the consumption of material. Accordingly, the cost of construction increases.

Do not try to guess the thickness of the walls from the foam block - calculate it at the design stage, because the quality and reliability of the structure depend on this. The house, built according to technical requirements, can withstand any frost with minimal heat loss: it will not release heat from the inside of the room and it will not let the cold outside.